Robotic vs. Conventional Palletizers: A Guide to Boosting Efficiency

Palletizing is essential but is often riddled with safety issues and inefficiencies. Fortunately, automation can transform this process, increasing safety, productivity and product quality. This blog will compare manual, conventional and robotic palletizing so you can make an informed decision when choosing a palletizing solution.

Understanding the Palletizing Process

Palletizing is the process of stacking and arranging goods and products onto a pallet to create a single, stable, organized load for shipping or transporting. Depalletizing is the process of unloading goods from stacked pallets and placing them in another area, such as a production line or onto another pallet to be shipped elsewhere.

Palletizing and depalletizing are critical in the manufacturing, warehousing and shipping industries because these processes increase the efficiency of handling goods, reduce damage and save space in the facility.

The Challenges of Manual and Conventional Palletizing

What is Manual Palletizing?

In manual palletizing operations, workers physically lift and stack boxes or bags onto pallets. Manual palletizing causes repetitive motions injuries because workers must bend and lift heavy boxes and bags. This results in downtime and absenteeism, as well as expensive medical bills, workers’ compensation claims and rising insurance premiums. It is also difficult to find and retain employees for these physically demanding, but boring positions.

Additionally, using manual labor to perform palletizing and depalletizing tasks leads to unstable pallets, damaged product and end-of-line bottlenecks as workers become fatigued.

What is a Conventional Palletizer?

Conventional palletizing machines remove the human element and replace it with large, fixed machinery that arranges products by layers on pallets. While palletizers increase efficiency when compared to manual palletizing, these machines may lack the flexibility to manage multiple products, and it can be difficult to integrate with other system components and production lines.

How Robotic Palletizers Revolutionize the Process

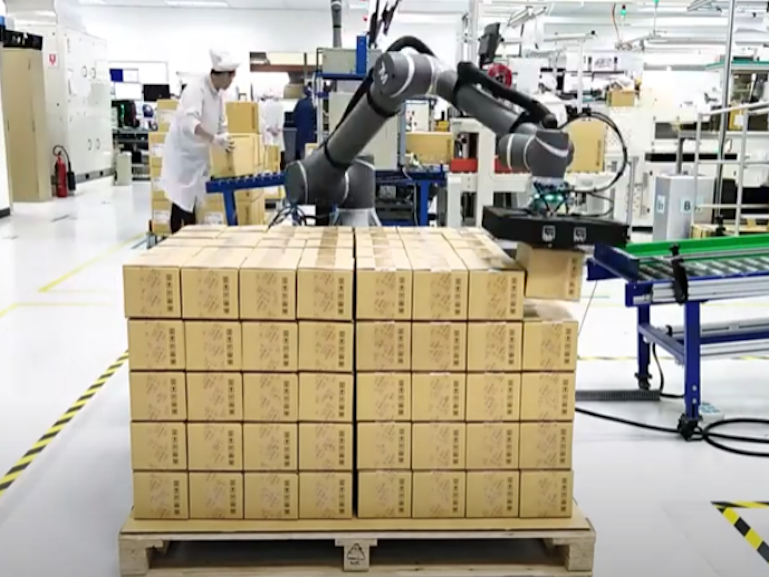

Robotic palletizers automate the process using a robotic arm outfitted with end-of-arm tooling to pick up, orient and place individual products into a stack, which is then moved as a single unit, resulting in less product handling, maximizing efficiency and minimizing product damage.

To operate, a robotic arm picks up and orients products and places them on the pallet, arranging them into a single unit load. Robotic palletizers repeat this action to construct layers of product, using slip or tier sheets if needed. Once a pallet is fully loaded, it is removed from the area by an outfeed conveyor and the process begins again with a new pallet.

What are the benefits of a cobot palletizer?

Collaborative robots are compact, flexible solutions designed with safety features that allow them to work alongside human employees. Cobot palletizers offer several benefits for your operation, including:

Minimized injuries: Free your team from this demanding task by using a cobot palletizer, which will help mitigate repetitive motion injuries, keeping workers safe and minimizing costs associated with injuries and absences.

Boosted productivity: Robotic palletizers work faster than manual workers and can operate continuously to eliminate bottlenecks and increase throughput.

Improved quality: Product damage may be reduced because cobot palletizers can handle stacks or individual products. They are also programmed to create stable, secure pallets, ensuring consistent, error-free stacking.

Unmatched flexibility: Robotic palletizers can handle a range of applications, including standard cases, mixed pallets and bags or can be customized for bales or heavy, hazardous materials. They can be programmed to handle multiple SKUs and complex patterns on a single line.

Lower operating costs: Using cobot palletizers reduces expenses related to labor, injuries and damaged products to provide a strong ROI.

Types of robotic palletizers

Classified by configuration and construction, robotic palletizers are available in several different types, including:

In-Line Palletizers: These consist of a single robotic palletizer and offer features such as the ability to place tier or slip sheets and dispense pallets. They can service one or multiple palletizing lines and employ articulated arms with specialized end of arm tooling.

Palletizing/Depalletizing: These can perform all the functions of an in-line palletizer, but can be used for depalletizing and will unload products from mixed pallets and sort them according to SKUs. However, these robots do not usually perform both functions – the term simply means the palletizer can be programmed for use as a depalletizer.

Layer-Forming Palletizers: These palletizers consist of an integrated system of robots with each performing a single task. One may layer products, while a second stacks them, which increases productivity, making them a great choice in high velocity/throughput applications.

Mixed-Configuration Palletizers: Capable of taking boxes and cases of varying sizes and shapes and creating a stable layer, mixed-case palletizers come in a variety of styles. A robot may be mounted to a track, allowing it to move between a series of pallets, select a product and then set it onto the receiving pallet in a stable configuration or a series of conveyors may feed product into a staging area where a robotic arm selects and orients the products, forming layers of configured products into a load that is then lifted onto a pallet by another robot.

How to Choose a Robotic Palletizer

When choosing a robotic palletizer for your operation, consider the following:

Product type: Noting the size, shape and material characteristics of the products being palletized, as well as the container type, dimensions and weight will help determine the required payload of the robot, as well as end-of-arm tooling requirements.

Palletizing needs: In addition to knowing the required throughput, consider the expected configuration of each pallet, including number of layers, different layer arrangements, if you anticipate mixed pallets and whether slip or tier sheets will be used.

Speed and accuracy requirements: Your robotic palletizer must be able to provide the necessary throughput, so select a palletizer with palletizing rates that match your needs. Take note of how accurately the robot can place product onto pallets while maintaining the required speed. You don’t want a robot that moves quickly, but doesn’t properly stack the pallet.

Flexibility: If your product mix changes frequently or pallet configurations may differ in the future, flexibility is important. Look for a robotic palletizer that can be reprogrammed or re-tooled to handle changes.

Product mix and pallet configuration: If you have a complex product mix or pallet configuration or a very high throughput application, several robotic palletizers may be needed. Typically, robotic palletizers can be purchased individually or as part of a system that allows multiple palletizers to run simultaneously.

Location: The location of the system, as well as that of the packing or production equipment it serves will determine how the palletizer is arranged, the required reach and what type of robotic arm is most suitable. Keep in mind that robotic palletizers and associated components can have a large footprint, so determine how much area will be dedicated to the palletizing operation and find a palletizer that meets these specifications.

Safety: Because safety is a priority, be certain a risk assessment is performed and the robotic palletizer comes with or can be equipped with safety features such as pallet guards, light curtains and emergency stop mechanisms. Cobots used in palletizing offer built-in safety features to ensure the safety of nearby workers.

Common Questions about Robotic Palletizers

Are palletizer machines easy to program

Yes, modern systems, especially cobots, feature intuitive interfaces that simplify programming and permit quick changeovers.

Can a palletizer handle fragile items?

Absolutely. With advanced end-of-arm tooling and precise motion control, robotic palletizers can handle delicate products gently and securely.

How fast can a robotic palletizer operate?

Application speed is dependent on the robot and specific requirements of the application, but modern systems are designed to keep pace with upstream product lines, often outperforming them.

Your Partner in Palletizing Automation

As a partner in your success, the automation experts at JHFOSTER can evaluate your specific needs to design and integrate a tailored solution that works for your palletizing operation. Ready to start working faster, smarter and safer? Contact the JHFOSTER team today to discuss your palletizing needs and request a quote.