How to Tell When Your Compressed Air System Needs New Filters

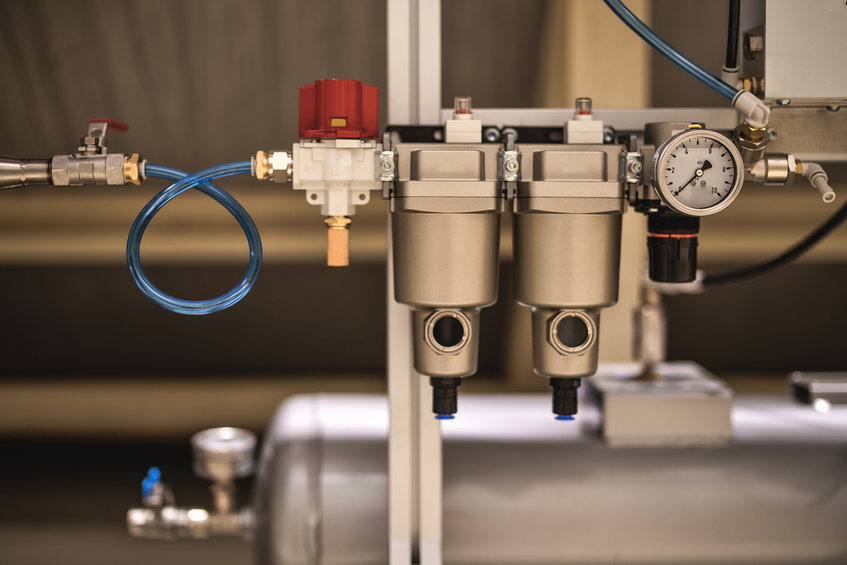

Using clean dry air is beneficial for compressed air systems in many ways. It will reduce wear and tear and maintenance required for pneumatic tools, machines, and devices used in the manufacturing environment and help maintain product quality and consistency. You can reduce machine downtime by having the proper filtration system in place while also increasing the longevity and efficiency of the equipment.

What if an Air Compressor has a clogged or worn filter?

clogged filters cause a drop in pressure which will make your Air Compressor less efficient.

How do I know which type of Air Filter is right for my Air Compressor?

Your Air Compressor may need a specific type of filter to keep your compressed air compliant. Make sure to use the filters recommended in the compressor manufacturers operators manual and replace them as directed.

What are common contaminants that may be found in Compressed Air Systems?

| Particles of Dust and Dirt | Water Vapor |

| Your Air Compressors location can affect what kinds of particles are traveling through your machine. If they stay in the airflow, these materials can damage pneumatic tools. They may also cause health risks for employees. | Naturally occurring water is in the air as vapor. A portion of this vapor carries into the compressed air. With high humidity in workspaces these particles could cause problems with continued exposure. Water vapor can cause higher rejection rates for plastic injection and spray painting. It can also cause corrosion in the pipe system and increased leakage. |

| Microorganisms | Lubricant and Oil |

| Many of the contaminating particles in compressed air can lead to the growth of microorganisms in pipes when they mix with the water and oil residues. Viruses and bacteria can multiply under these conditions which would further contaminate the air coming from your pneumatic devices. These particulates are removable if you have the proper filters in place. | Oil particles are prevalent in compressed air. The amount of oil particles that pass through depends on the type of machine you’re using. Factors that contribute to this include the current performance of your Air Compressor, its working condition and age. |

What are indications that my Air Compressor needs a new filter?

Air Compressors have filters that keep contaminants out of the equipment. An Air Filter is an important part of this process.

Less-than-optimal performance:

If your Air Compressor acts improperly after getting a new Air Filter, it may be a good time for a close inspection. Waiting too long to replace your Air Filter can lead to less-than-optimal performance.

Manufacturer’s recommendation:

Your Air Compressor manufacturer will typically recommend changing Air Filters every 2,000 hours. They may recommend changing it more frequently.

Noticeable wear

It is best not to risk running your air compressor with a damaged Air Filter. If your filter looks worn down or shows signs of damage, it is a good idea to replace it. This type of wear can happen prior to the 2,000 hour mark.

Why is Air Filter replacement necessary?

Three key reasons to replace Air Filters:

- Reduction of machine shutdowns: Your Air Compressor could malfunction due to a faulty Air Filter. If you don’t have a backup Air Compressor ready, you may need to shut down operations for a few days.

- Prevention of costly repairs: Replacing your air filter every 2,000 hours is a wise step toward preventing performance issues with your Air Compressor.

- Increasing the lifespan of your machine: Air Filters block contaminants and keep your Air Compressor running at an optimal level of performance.

What can I do if I have questions regarding Air Filters for my Air Compressor?

One of our technicians would be happy to discuss your Air Filter inquiries.

We have experienced and knowledgeable consultants at JHFOSTER.

At JHFOSTER we work with all types of Compressed Air systems and their components.

You can trust us to meet your Air Filter and Air Compressor requirements.

A JHFOSTER representative is available at 651.998.7428 or 855.688.0065