How to Select a High-Quality Industrial Electric Actuator

With the rise of robotics and automation, electric linear actuators have become an essential component in the processing equipment, assembly machinery, machine tools and robots found in almost every industrial facility. Used to convert the rotary motion of an electric motor into linear motion, electric linear actuators enable industrial equipment to do its job; however, choosing a high-quality model that is suitable for an application can be a challenge. This blog will outline best-in-class manufacturing practices and provide information on the selection process.

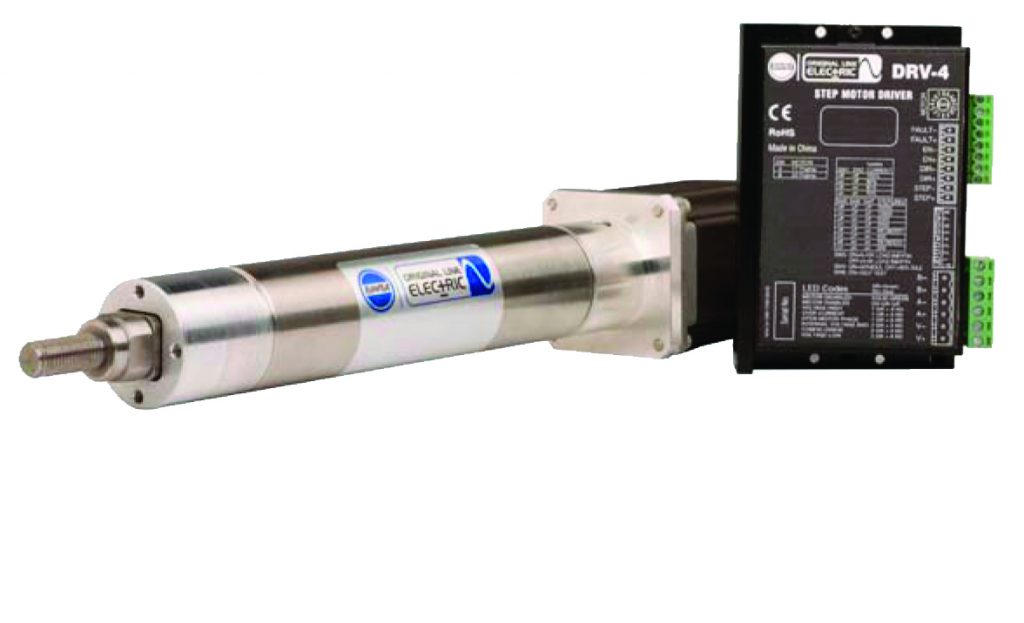

How Electric Linear Actuators are Made

The manufacturing process begins with the electric motor, which has two main components: a stator, and rotor, which sits in the middle of the stator’s magnetic field causing it to spin, thus creating the motion. Motor assembly is usually fully automated, monitored and optimized to ensure quality.

Following motor assembly, the linear actuator is built in a more hands-on manner using trained technicians that assemble the unit based on engineered specifications. Typically, components such as gearboxes, drive screws and circuit boards are selected and tested to provide reliable, powerful and long-lasting actuators. Best-in-class manufacturers inspect each component and monitor each step in the assembly process to ensure the highest quality final product.

Once fully assembled, reliable manufacturers employ quality control teams that inspect the unit. Next, the linear actuator is subjected to testing to ensure that requirements for operating performance temperature, IP ratings and duty cycles are met. If the unit passes all the necessary inspections, it is sent to distribution centers and is likely examined once again to ensure that it meets the specifications and was not damaged during shipping. At this point, the electric linear actuator is ready to be sent along to its final destination – your industrial application where it should provide long life and high-quality performance.

How to Select an Electric Linear Actuator

Because industrial electric linear actuators come in many sizes and with a variety of motor choices and because each application has different requirements, the selection process can seem intimidating. However, answering the following questions should narrow down the choices so you can determine which linear actuator will best fit your application.

- How much force is required? This may be the weight of the object to be moved including the friction the linear actuator will need to overcome. Also consider the orientation of the load and actuator, whether or not the load is externally guided and in what direction the actuator will need to move. Any linear actuators that are not capable of producing enough force for the application can be eliminated from the selection process.

- How far does the linear actuator need to travel? Once you know how far the linear actuator needs to move in your application, you can determine the required stroke length. Keep in mind that when using rod style actuators, the longer the stroke, the longer the actuator will be when fully retracted, which is an important consideration if the unit needs to fit into an existing space. A rod-less style actuator maybe be necessary if space is limited.

- What is the required speed? Does the application require fast or slow motion? The speed of linear actuators is measured in distance per second. Typically, linear actuators with higher forces provide slower speeds, so determining the required combination of speed and force will eliminate any actuators that do not provide adequate speed and force to meet your specifications. Acceleration and deceleration requirements need to be considered also.

- What is the expected duty cycle? How often the actuator will operate, also called the duty cycle, is an important consideration. The duty cycle is based on the number of repetitions per unit of time. Reputable manufacturers should provide this information, and it is an important consideration for reliability.

- What is the operating environment? Environmental factors such as temperature, moisture, vibration and shock can impact operation, as can harsh outdoor conditions. For this reason, it is important to note these challenges as it may necessitate purchasing a linear actuator with the proper protection rating or the provision of external protection.

- How much Precision is required? Position accuracy and repeatability are also important considerations for many applications.

Because linear actuators are an integral component in industrial operations, it is crucial that they are high quality and that the right unit is selected for the application. The above-mentioned steps should help you choose a suitable actuator and using a reliable supplier will ensure that you are purchasing a well-made product.

For more information on selecting an industrial electric linear actuator, please reach out to a representative at JHFOSTER.