Food Manufacturing Companies Rely on Pneumatic Actuators

Efficiency, reliability and cleanliness are top priorities for food manufacturing companies, so it’s no surprise that pneumatic actuators are frequently the technology of choice for automated equipment that processes and packages food and beverage products. This blog will focus on the advantages pneumatic actuators provide in various applications within the industrial food industry.

What is an Actuator?

A primer on actuator technologies may be in order before discussing the advantages and applications for pneumatic actuators in the food manufacturing industry.

Actuators are motion control components used within automated machinery to convert energy into lifting, ejecting, pressing, clamping and other motions.

Actuators are categorized by the type of motion they produce, with linear actuators providing straight-line motion and rotary actuators offering circular motion, as well as by the form of energy that powers that motion.

There are three main actuator types, including:

- Hydraulic Actuators: Hydraulic actuators rely on hydraulic fluid to create and control movement. This type of actuator provides significant force, strength and power and offers reliable operation and long service life.

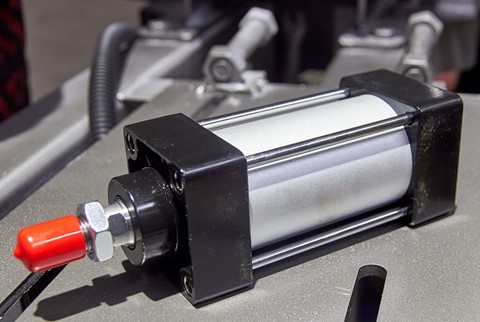

- Pneumatic Actuators: Pneumatic actuators, or air actuators, convert compressed air into mechanical energy to create force. While air-powered actuators are often chosen based on their initial low cost, they offer simple, reliable designs that are capable of high speeds, provide accurate and repeatable motion profiles and can be a clean technology in industries, such as food and beverage processing, where hygienic operation is essential.

- Electric Actuators: Electric actuators use electrical currents and an electric motor to create the force that generates motion. They can be somewhat complex and are often costly to purchase, but deliver precise control, accurate positioning, excellent response times, high speeds and small sizes.

The Advantages of Pneumatic Actuators in Food Manufacturing

Recognized as a clean, safe and reliable technology, air-powered actuators deliver high levels of performance and many advantages for food manufacturing companies, including:

| Clean Technology | As pneumatic actuators are air-powered devices, they are not subject to leaking oil as hydraulic actuators are, which is essential in the food and beverage processing industry, where contamination is strictly prohibited. However, it is important to ensure the cleanliness of the compressed air to avoid contamination risks. In addition, with proper design and options, air-powered actuators are rugged enough to withstand the harsh cleaning regimes used in the industrial food industry. |

| Pneumatic actuators can provide high forces and fast speeds in motion control applications thanks to the air pressure and flow within the device. Food and beverage manufacturers can rely on air actuators to provide high levels of performance in an industry that requires the most efficient operations to remain competitive. | High forces and speeds |

| Precision | Air actuators provide enough precision to handle delicate food items and can do so gently to successfully avoid damaging the product during processing and packaging to help maintain product quality. |

| Because they are air powered, pneumatic actuators do not overheat in food and beverage manufacturing operations where they may encounter high temperatures during processing. Further, air actuators can be built to withstand the harsh operating conditions, such as extreme temperatures, humidity and moisture, that are present in the food processing industry. | Durability |

| Reliability | The simple design and robust construction of pneumatic actuators enables long-lasting performance and minimizes the need for maintenance, which reduces unplanned equipment downtime and helps ensure productivity and throughput on fast-paced food manufacturing equipment. |

| Because they are simple in design and built to last in harsh food processing environments, air-powered actuators have a low upfront cost and a minimal cost over their lifecycle, making them a cost-effective motion control device. | Cost Effectiveness |

Applications for Air Actuators in Food Processing

With all the benefits they deliver, it is no surprise that a pneumatic actuator is often the go-to choice when designing food and beverage manufacturing equipment.

You’re likely to find an air actuator in the following food processing operations:

- Pick-and-place: Because they offer cleanliness in addition to precision and high speeds, pneumatic actuators are often used in cobots end of arm tooling designed for pick-and-place activities, such as picking toppings when assembling pizzas and sandwiches and picking and placing items for packaging.

- Material handling: Pneumatic actuators are widely used in material handling equipment and conveyors in food manufacturing facilities because they offer high speeds and strong forces capable of moving products from one stage of production to the next or along packaging and labeling lines with high levels of reliability and safety, while ensuring cleanliness in operations.

- Food and Beverage Processing: Due to their cleanliness, safety, precision, speed and high levels of reliability, air-powered actuators can be found in all types of food and beverage processing equipment. In the dairy industry, pneumatic actuators may be used in equipment that pasteurizes milk or controls cheese production. In beverage production, air actuators may be used in carbonation processes or bottling and labeling applications. In meat and poultry operations, pneumatic actuators may be used to encourage the precise flow of marinades or sauces. And in baked goods production, air-powered actuators may be used in equipment that dispenses ingredients or in cobots that decorate cakes.

- Packaging Lines: The benefits of pneumatic actuators also apply to food packaging lines where they may be employed in equipment that picks and places items for packaging, seals bags or dispenses glue on boxes, all while providing clean, efficient and reliable operation.

What to Look for in Pneumatic Actuators for the Food Industry

When selecting a pneumatic actuator for sanitary food and beverage processing operations, it is crucial to ensure that it meets the hygienic demands of the application. For this reason, it may be necessary to seek out an air actuator that offers:

Compliance with food safety regulations

In the production of food and beverages, there are many regulations with which to comply, so be sure that the selected air actuator meets any necessary mandates. As discussed earlier, the compressed air quality should also meet the guidelines for the application in order to ensure compliance.

Food-grade materials

Pneumatic actuators that come in contact with food products should be composed of food-grade materials to ensure product integrity and regulatory compliance.

Smooth surfaces

Smooth surfaces ensure that there are no nooks or crevices in the device that may harbor food particles or contaminants that can lead to quality issues.

Pneumatic actuators deliver a solid solution for food manufacturing companies as they provide efficient, reliable and clean motion in an industry that demands the highest levels of quality and productivity. JHFOSTER is standing by to provide assistance with selecting an air-powered actuator for your food processing application.