Exploring the Advantages of Wireless Pressure Sensors

Pressure is one of the most important measurements in the manufacturing and process industries because accurate measurement and control of pressure influences safety, process and energy efficiency, product quality and costs. For this reason, there is a mind-boggling array of pressure sensor technologies available to suit every application. This blog will explore the importance of pressure measurement, the different types of pressure sensors and the advantages of wireless pressure sensors.

The Importance of Measuring Pressure

The Importance of Measuring Pressure

Pressure is a crucial measurement in industry. Industrial pressure sensors are used to measure and monitor the pressure of process flows, fluid and gas flows through pipelines or piping systems, measure the fill level of tanks and vessels and even detect leaks in a facility.

Accurate measurement and control of pressure allows users to ensure safety, improve process control, optimize energy efficiency, ensure product quality and better control operational costs in the following ways:

- Safety: Keeping a close eye on pressure allows manufacturers to be sure that equipment and processes are well controlled and operating safely. Pressure sensors can alert users to pressures that are too high before an accident or explosion occurs.

- Process Control: By monitoring pressure, operators can better control the process so that it is running optimally, enhancing the efficiency of operations and ensuring that the process is operating within specifications.

- Energy Efficiency: Because pressure can be directly related to energy usage of equipment, monitoring and controlling pressure allows users to reduce pressures that are too high, which will in turn reduce energy consumption and utility costs.

- Quality Control: Pressures within the process can directly impact the quality of the product, so measuring and controlling pressure to keep it within proper specifications allows manufacturers and processors to produce products that are of the highest quality.

- Reducing Costs: By measuring pressure to avoid accidents, improve process and equipment efficiency, optimize energy usage and control quality, processors and manufacturers can reduce downtime and unnecessary expenses, including utility costs and costs associated with scrap and wasted product that results from process upsets.

Types of Pressure Sensors

Because pressure measurement is an essential tool for industrial and manufacturing processes, there are many types of pressure sensors to choose from.

But before delving into that, let’s look at the three most common methods of pressure measurement:

Gauge Pressure

This is the pressure measured relative to the ambient atmospheric pressure. A gauge pressure sensor features two ports, allowing the media at the reference pressure and at the actual pressure.

Absolute Pressure

Absolute pressure is the measurement of pressure relative to a reference of zero pressure.

Differential Pressure

This is the difference in pressure between two points in the process. Differential pressure sensors are often used to measure the flow of fluid or gas in a pipeline.

The method of pressure measurement used will be determined by what is needed for the application, as the way in which pressure is measured has a direct influence over the accuracy of measurement. Once you’ve determined which method of pressure measurement is required, the next step is making a selection from the various types of pressure sensor technologies that are available.

For reference, pressure sensors are the devices used to take the actual pressure measurements. These devices detect and monitor the pressure of liquids or gases so that operators can use the provided measurement data to better control equipment or the process to enhance safety, efficiency, quality, etc. Pressure sensors work by detecting a force and then converting it into an output signal that is relative to the strength of the pressure being exerted, providing operators with an accurate pressure measurement.

There are a variety of pressure sensor technologies available from simple pressure gauges to differential pressure sensors to more complex electronic pressure sensors and digital pressure sensors. Because more industrial facilities are opting to go wireless with pressure sensors, this blog will discuss wireless pressure sensors from Banner Engineering Corp., which provides a variety of wireless pressure sensors with innovative features.

Wireless Pressure Sensors

Wireless pressure sensors are pressure measurement devices that rely on wireless technology to transmit data about pressure measurements to operators. The pressure sensor converts the pressure measurement into an electronic signal and transmits this output wirelessly to a receiver or monitoring system. Many industrial users are employing wireless pressure sensors because they are often easier to install, offer improved accuracy and allow remote monitoring.

Banner Engineering Corp. offers a variety of wireless pressure sensor options including:

The Q45DPSD differential pressure sensor node, which combines a differential pressure sensor with a reliable industrial wireless architecture into one package, eliminating the need for ordering multiple components. The industrial grade, battery-powered device can be used to wirelessly transmit differential pressure levels to a wireless controller or gateway for remote monitoring of critical systems.

The Q45PS all-in-one pressure sensor and wireless node measures air, gas and fluid pressure of systems and equipment. It can be used with cloud-based software to create an end-to-end IIoT solution that helps users identify and resolve problems more quickly, enabling better, data-driven decisions.

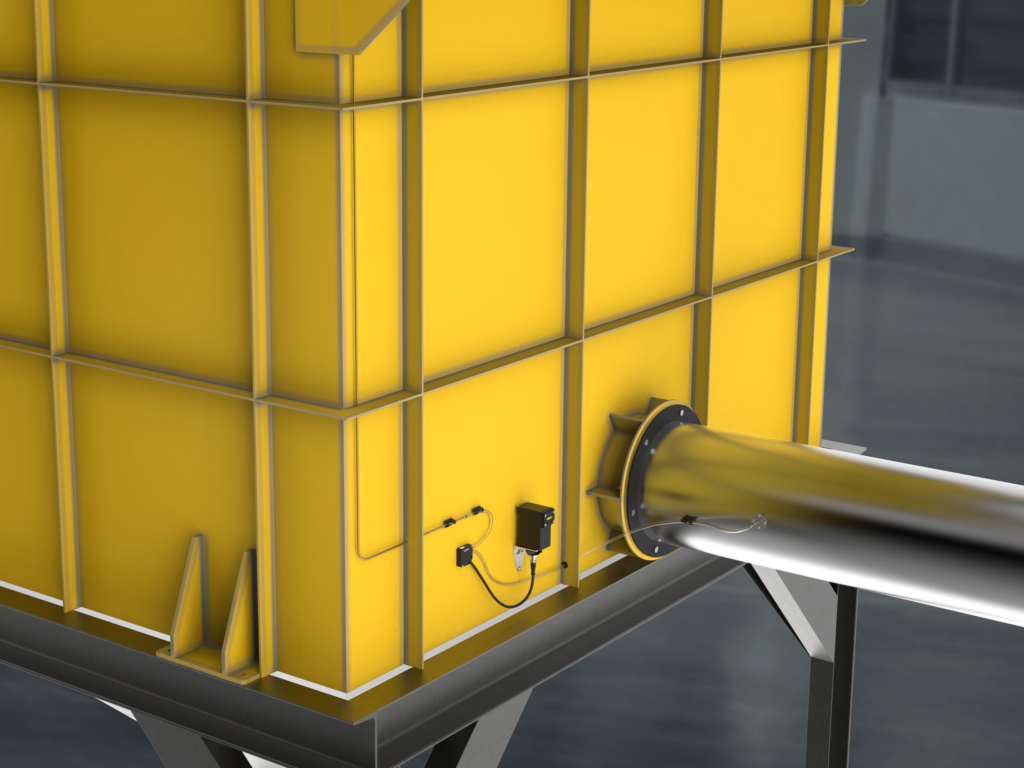

The wireless Q45UPSD pressure monitoring node and cabled transducer accessories combine a media-isolated pressure sensor with a reliable wireless architecture into one packaged solution. This solution monitors pressurized systems in remote locations without human intervention. The industrial-grade, battery-powered device can wirelessly transmit pressure levels to a wireless controller/gateway for remote monitoring of critical systems.

Pressure sensors combined with wireless technologies connect remote or inaccessible processes with operators who rely on the pressure measurements for safety, troubleshooting, predictive maintenance, efficiency improvements, product quality enhancements and other reasons.

Wireless pressure sensors allow operators to monitor and manage equipment and processes in real time from anywhere, such as spaces where traditional wired pressure sensors are impractical, too expensive, inaccessible or ineffective. Wireless pressure sensors from Banner Engineering Corp. allow processors and manufacturers to adapt modern technology and its benefits to their environment. To learn more about wireless pressure sensors or other pressure sensor technologies, please contact Sensors Incorporated, a Tavoron company today.