Category: Safety

Safety-Integrated Motion Control Allows Safety and Productivity to Co-Exist

Ultimately, the objective of any manufacturing operation is to produce product. Accordingly, corporate goals often focus on efficiency, quality and productivity. While some companies view safety as a necessary evil or, worse, a costly drain on productivity, top-tier manufacturers rank safety as a priority and embed it deeply into the culture of the company. Furthering […]

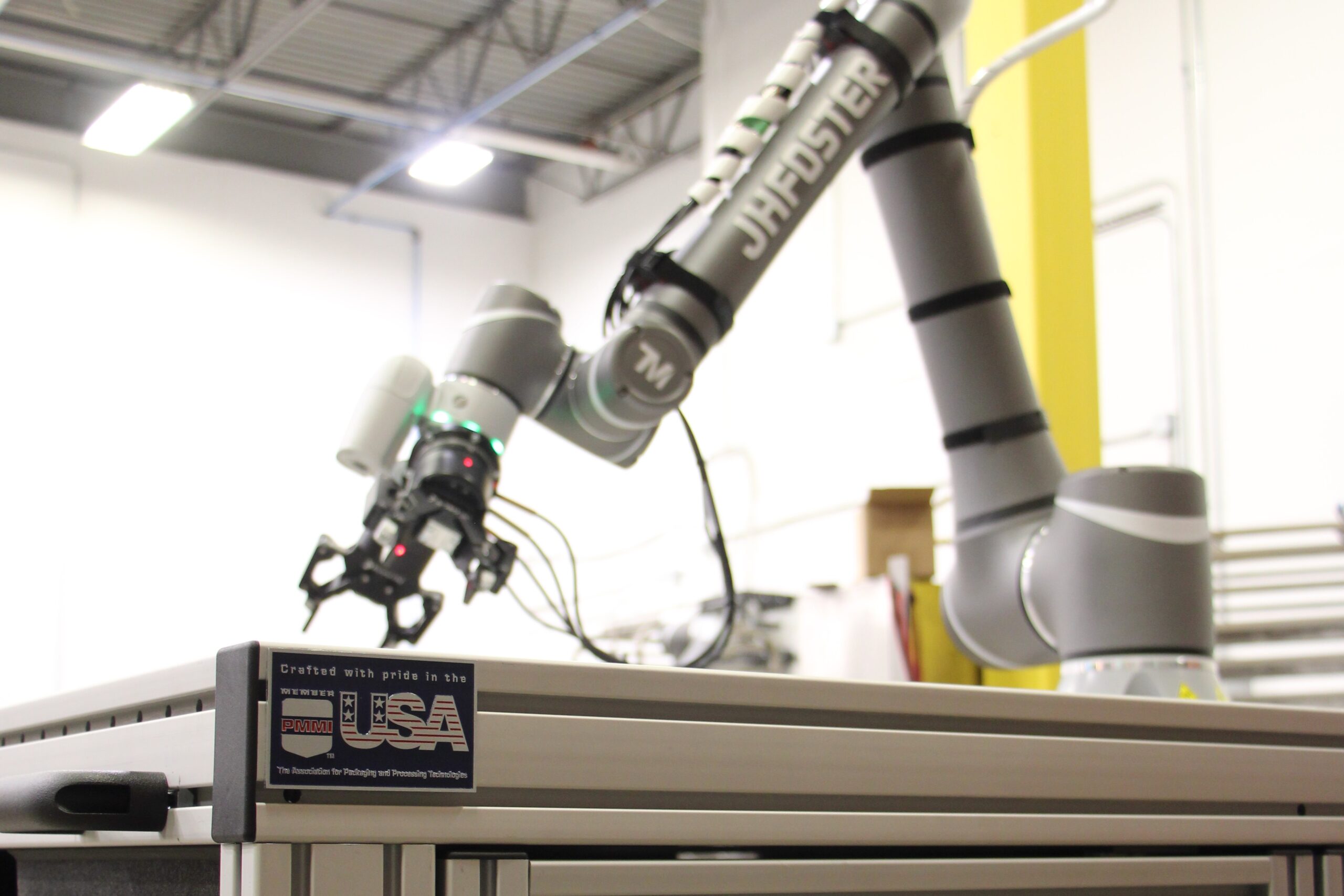

Are Collaborative Robots More Efficient than Workers?

The core motivation at the heart of technological advances is the desire to create tools that provide an improvement in our effectiveness as workers and, in turn, our business as a whole. As advances in technology continue, they broaden the boundaries and landscape of what was thought possible, and forces employers to be constantly reexamining […]

What Are the Signs Your Collaborative Robot Needs Repair?

Your collaborative robot, also known as a cobot, has been working hard to increase efficiency and reliability within production. This new technology has quickly paid for itself and has become indispensable for human coworkers working alongside the robot. Or perhaps you have used robotic technology for quite some time, and it has become a staple […]

Ways Robotic Technology Enhances Worker Safety

Robotic technology is becoming a mainstay of many industrial environments. From packaging applications to lab analysis and testing, robots are being used for a variety of tasks previously performed by humans. As robotic technology rolls out, many companies are wondering about how safe robots are for their human coworkers. Are robots truly safe to be […]

Safety Pointers When Working with Compressed Air Systems

Compressed air systems are used for varying industries, from agriculture to pharmaceutical manufacturing, requires workers to operate systems within safety parameters. Any sudden changes in pressure or malfunction equipment may cause an accident that could damage products or applications as well as injure workers. Practicing safety best practices allows workers to take all required precautions […]

Safe Operating Procedures for Compressed Air Systems

In the world of manufacturing, air compressors play a far more vital role in day-to-day proceedings than most people realize. But at the same time, it’s also one of the more dangerous pieces of equipment on a shop floor – which is why employees should proceed with extreme caution during their operation. Not only can […]

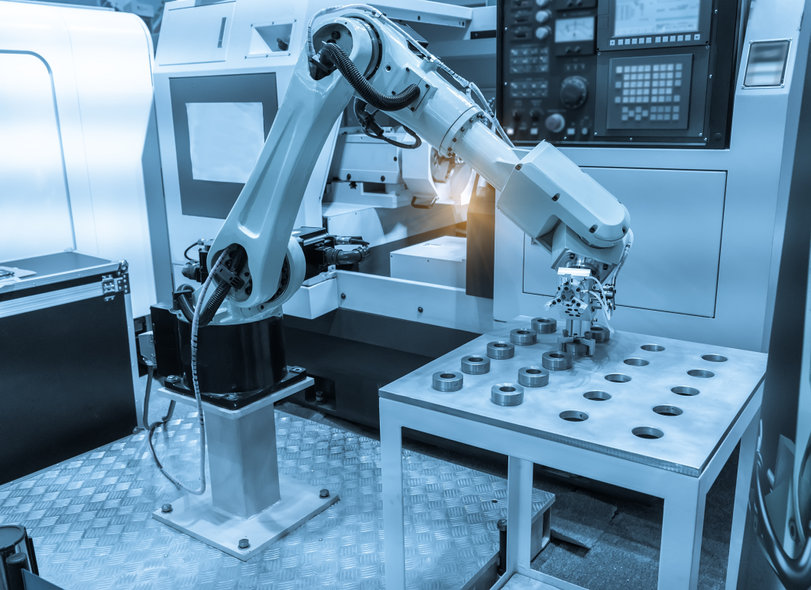

The Safety Benefits of Automation

Workplace safety is the most important thing a manufacturing company needs to consider. When workers aren’t safe, everything else suffers, including quality, productivity and operations. And it turns out, one of the best ways to improve worker safety is to enhance your factory’s automation levels. Automation can help keep workers safer in a number of […]