Category: Compressed Air

Compressed Air Rebates Save You Energy and Money

Have you ever winced when looking at your power bill? Whether you’re looking at your company’s power bill or your very own home’s electric bill, that number after the dollar sign can be less than ideal. What if we told you that you could lower it by using Compressed Air Rebates and Incentives? You probably […]

Choose the Right Vacuum Pump for Your Compressed Air System

We say this pretty often about choosing equipment. The saying holds true, though. Choosing the right Vacuum Pump for your Compressed Air System really depends on the application you are using it for. There are five main types of vacuum pumps. Each is suited best for a specific purpose. So let’s break down what a […]

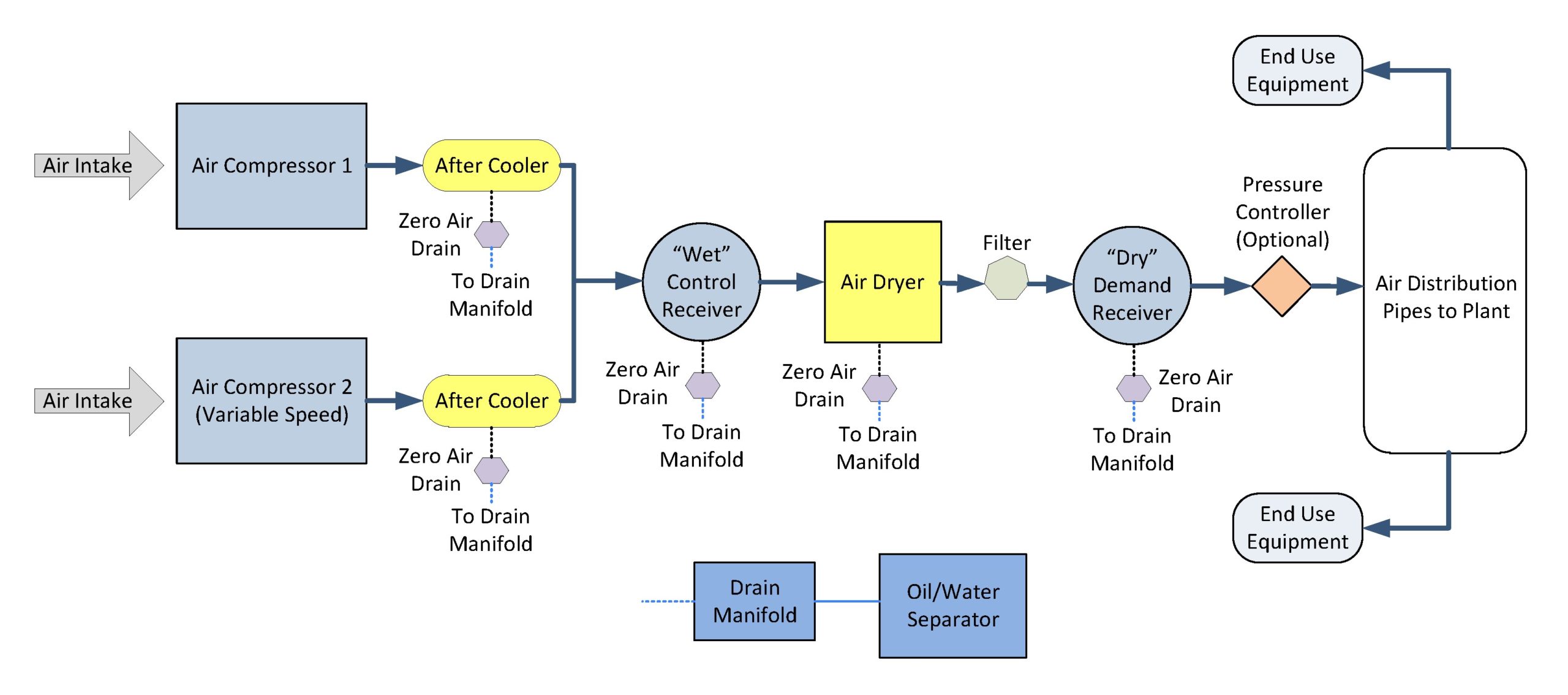

Use Control (Wet) Storage for an Efficient Compressed Air System

When evaluating a compressed air system and the proper use of storage, many people misunderstand control storage. Many people refer to control storage as wet, or primary storage. However, the term control storage is more reflective of its main function – to maximize the operation of the compressor control. For the purpose of this post, […]

How to Remove Water from Your Compressed Air System

Condensate Management and Filtration You need to supply clean, dry compressed air to your tools, equipment, and system processes. However, how exactly do you ensure that this air is clean and pure? By using filtration and condensate management. If you haven’t selected compressed air accessories to manage condensation, we will go over how to do […]

Your Ultimate Guide to Medical-grade Air Compressors

The medical industry is no doubt busier than ever. The effects of COVID-19 have changed the medical industry forever. Efficiency, sterility, and cleanliness are at an all-time high of importance. Clinics are trying to ensure that their patients are kept healthy and that nothing gets in their way of healing. The question is: how can […]

How To Improve Efficiency Using Compressed Air Storage

With today’s ever-increasing focus on improving manufacturing efficiency and reliability, all aspects of the manufacturing process should be examined. Energy audits of manufacturing plants have shown that compressed air systems are often not the most efficient systems. However, increasing efficiency in one area of a compressed air system can improve your energy bill: compressed air […]

Use Demand (Dry) Storage for an Efficient Compressed Air System

This post will focus on a type of supply-side storage: demand (dry) storage. Before diving in, remember that you should consider control and demand storage as separate storage solutions based on their purpose. When using control (wet) storage in your system, the main goal should be improving the efficiency of the compressor controls. Other issues […]

Why Oil-Free Compressors are the Best Option in Most Applications

There is an old adage which is also a law of physics; what goes in will, eventually, come out. This applies to compressor lubricants in oil-flooded rotary screw compressors, too. At a rate of 2 ppm carryover, an oil-flooded 100 hp compressor operating for one year (8000 hrs) will introduce over 4 gallons of lubricant […]

The Application and Use of Heatless Regenerative Air Dryers

The use of heatless regenerative air dryers in the compressed air world has increased because of the demand for clean, dry compressed air. Heatless dryers are named as such because they do not use any outside sources for heat. Not only in traditional industrial applications but also in clean industries such as medical, electronics, food, […]

Protect Your Compressed Air Equipment from the Summer Heat

It is a well-known fact that high temperatures have never been kind to technology. This holds true for even your compressor system. Have you noticed that summer heat affects compressed air systems within your company? Fear not! We will tell you WHY the summer heat is affecting your system and the changes you can make […]