Category: Compressed Air

Building Pneumatic Circuits

Pneumatic motion circuits can encompass a huge variety of components and applications across hundreds of industries. How do you know where to begin? At the very basic, there are seven components common to most pneumatic systems: Air compressors are necessary to start the whole process – without pressurized air, there is no motion! Compressors come […]

Importance of Sensors and Position Sensing

Numerous automated machinery and equipment applications that use pneumatic cylinders also utilize sensors to detect the linear position of the piston, position feedback, and travel within a given operation. Depending on where a sensor or switch is mounted, the sensor can detect extension, retraction, or individual positions along the cylinder body. Accurate positioning is incredibly […]

What Are The Most Common Repairs For An Industrial Air Compressor?

Most industrial air compressors are worked hard. Used to produce compressed air for pneumatic tools, actuators, grippers, conveyors, and spray systems, if the plant is running the industrial air compressor is running. That often means 24×7 operation. Modern compressors, especially the rotary screw type, are very reliable. Even with appropriate maintenance though, problems can still […]

How Much Does it Cost to Install and Operate a Quincy Air Compressor?

Air compressors and compressed air systems are a staple in a variety of industries — from medical to automotive to manufacturing. And while air compressors can help streamline production efficiency and reduce operating costs over the long term, it goes without saying that an appliance such as this does come with an upfront cost. And […]

The Minimum Operating Temperature for an Oil-less Compressor?

There’s a winter cold snap and you need to fill your tires with air to offset a loss in air pressure caused by the weather. You pull into the service station near your house only to see a sign on the air compressor that the device is frozen and out of service. It’s a problem […]

The Difference Between Medical Oxygen & Industrial Oxygen

It’s a scientific fact that every part of the body needs oxygen to survive. In fact, that’s the main purpose of the body’s respiratory system — to take in oxygen and breathe out carbon dioxide. You might, however, be surprised to learn that there’s more than one type of oxygen — and two of these […]

What Are The Most Common Repairs For An Oil-free Air Compressor?

One of the benefits touted for oil-free air compressors is reduced maintenance. While there are differences in what oil-free and oil-injected compressors need, neither type will provide reliable operation with no maintenance at all. What’s more, while oil-free compressors may need less frequent attention it might be argued that they need overhauling more often. Here […]

How Long Does It Take To Install A Compressed Air System?

Whether you’re looking to power tools in a machine shop or equipment on the factory floor, a compressed air system can help streamline productivity and efficiency in an industrial environment. But unlike the portable air compressors that you may have around the home to inflate tires and power certain handheld tools in your workshop, a […]

How Do I Control Contaminants In My Compressed Air System?

Contaminants in compressed air are bad for business. They degrade product quality, impair the safety and efficiency of manufacturing equipment, and can sicken customers and end users. Fortunately, there are proven methods and techniques for taking them out before they affect anyone’s health or the financial bottom line. Before detailing these though, it is important […]

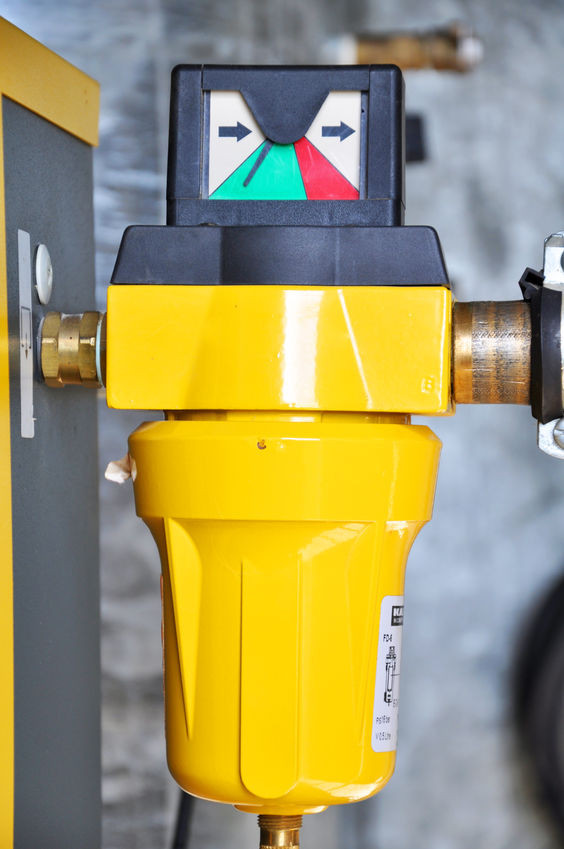

How Often Should Industrial Air Compressor Filters Be Replaced?

An air compressor filter keeps debris and other contaminants from reaching the rest of the system. This keeps compressed air clean and also prevents damage to your compressed air system caused by the contaminants. This means more efficiency for you and a decreased chance of expensive shutdown. Replacing your filter on time prevents your filtration […]