Category: AFFS

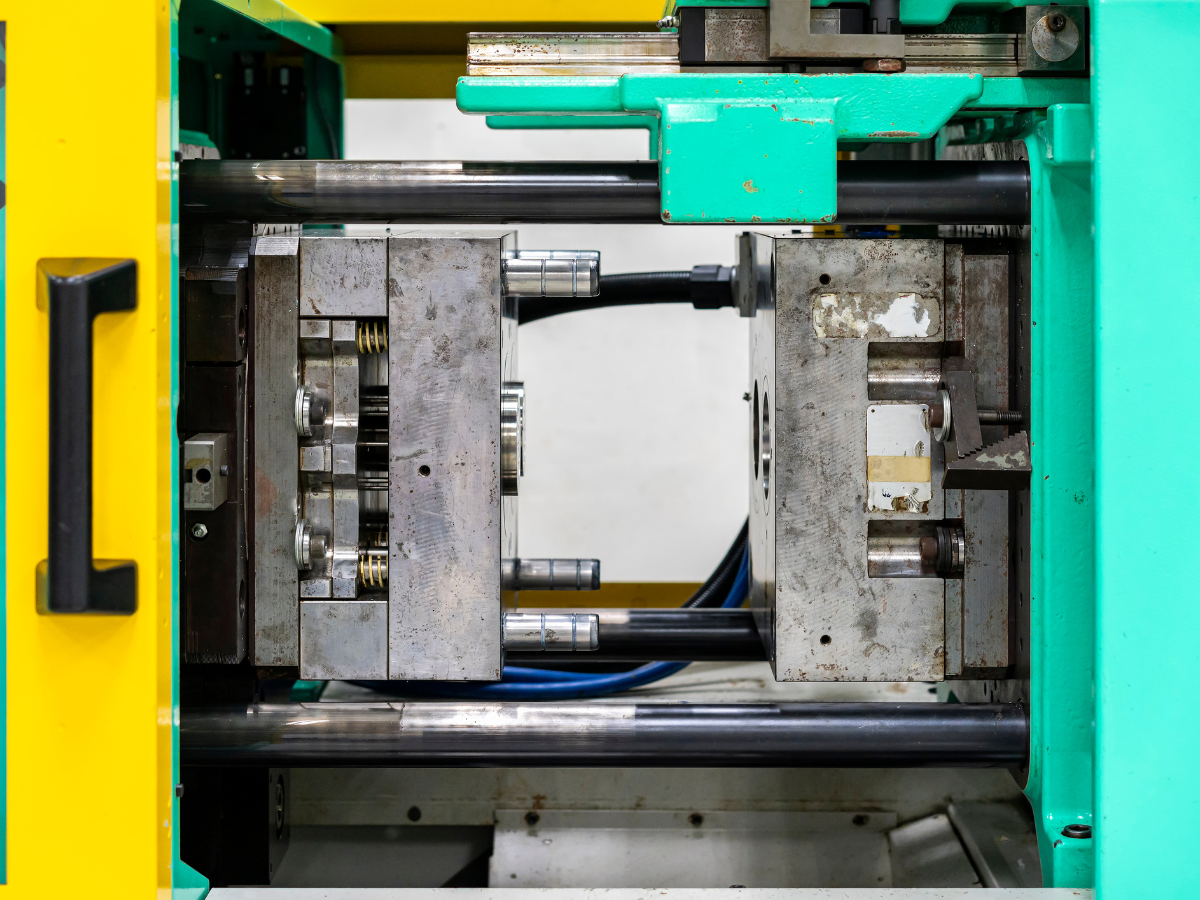

Injection Molding Techniques Call for Flexible Parts Feeding Systems

Traditional injection molding typically involves the use of volumetric and gravimetric feeders that precisely measure raw plastic granules, powders or pellets into the process. However, newer injection molding techniques – over molding and insert molding – call for an additional feeding system, an automated and flexible feeding system that can efficiently and accurately pick and […]

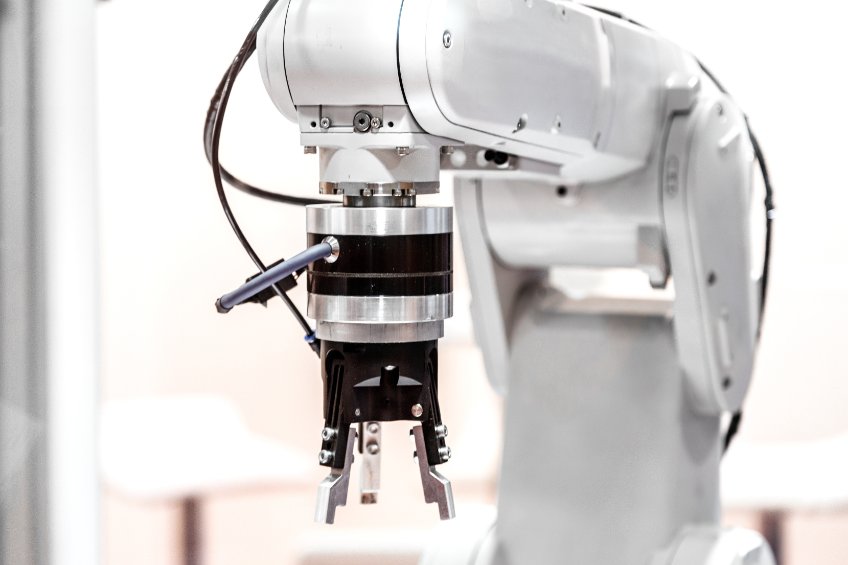

Integration of Feeders and Cobots Revolutionizes Material Handling

As manufacturers continue to seek ways to improve their productivity and efficiency, many are turning to automated feeding systems because the technology significantly speeds up the process of feeding parts to conveyors and assembly lines and improves the accuracy and consistency of material handling, enhancing productivity and throughput. To further boost efficiency, flexible feeding systems […]

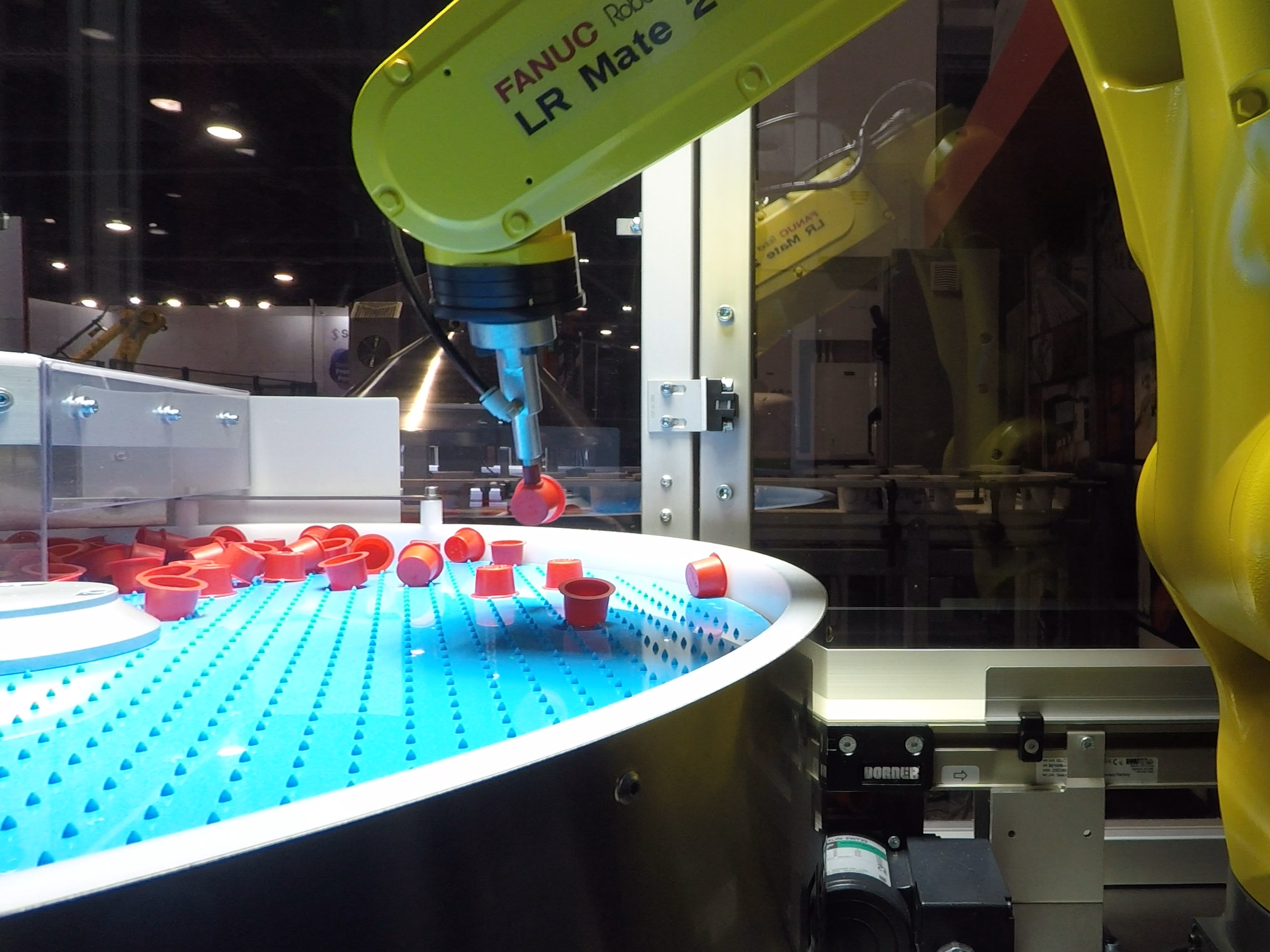

The Automated Flex Feeder System Advantages over Bowl Feeders

Faced with mounting pressure to improve efficiency, accuracy and quality, many manufacturers employ automated feeding systems to further boost throughput and reduce the burden on manual laborers. Automated feeding systems enhance productivity because they quickly separate bulk parts and place them in the proper orientation so they are consistently fed onto an assembly or production […]