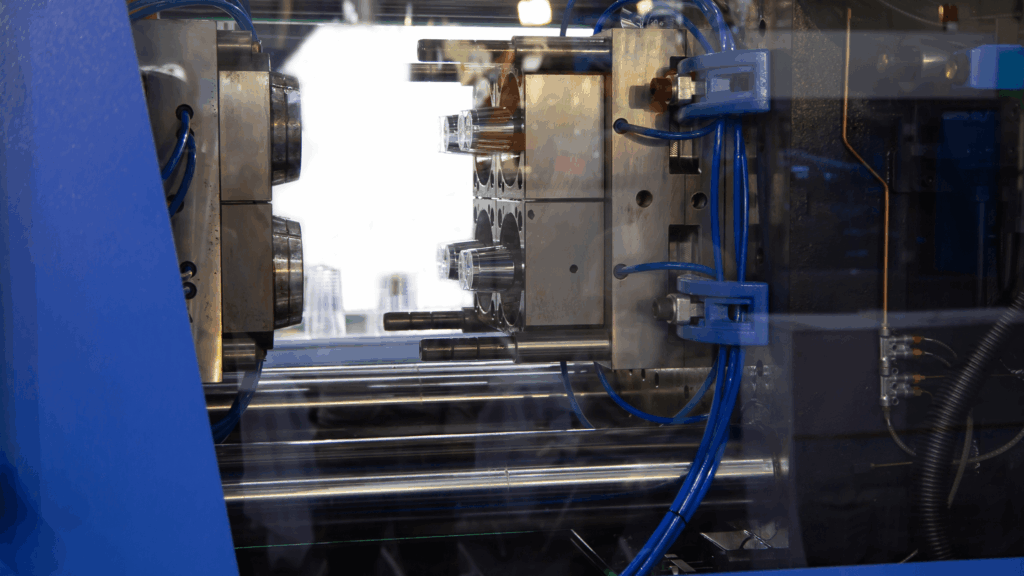

Injection Molding Automation: Upstream & Downstream Processes

Injection molding is the ideal solution for mass production, but the process includes multiple steps, many of which are repetitive, labor intensive and demand precision. Automating these tasks is the key to reducing injuries, boosting throughput and improving quality.

While many manufacturers automate part removal, the real competitive advantage comes from automating the entire workflow, especially the often-overlooked downstream processes. When upstream and downstream injection molding processes are automated, they become automatic systems where robotics and controls, usually PLCs, are integrated to manage the process – from part extraction to post-processing – with minimal human intervention.

This blog explains how it all works together to bring higher levels of efficiency, quality and safety to your business.

Common Upstream Injection Molding Automation

Upstream injection molding automation includes tasks that are commonly performed at the molding machine. JHFOSTER provides solutions to automate these foundational, high-repetition tasks.

Automated upstream processes include:

Part extraction: Using robots to unload finished parts from the machine.

Insert loading: Precisely placing inserts, such as metal pins, blades or clips, into the mold prior to injection to increase speed and precision.

Over-molding: Automating the process of combining two or more separately molded parts to create a single part.

In-mold labeling (IML): Automatically placing labels or decorations into the mold during the molding cycle.

Unlock New Efficiency: Downstream (Post-Process) Automation Opportunities

Injection molders miss significant gains by managing downstream applications with manual labor. Thanks to advances in robotics, vision systems and end-of-arm tooling, all post-process tasks can be automated, creating a key opportunity to unlock new efficiencies in the injection molding process.

Automated downstream injection molding processes include:

Machine tending: Robots pick finished parts and place them into a CNC machine or other secondary processing equipment.

Pick and place: Transferring parts to conveyors for assembly, packaging or printing.

Trimming and deflashing: Using robots to precisely trim or clip excess material, sprues and runners from the part.

Assembly: Performing complex assembly of molded parts, including the precise dispensing of adhesives and sealants.

Testing and inspection: Integrating robotic automation with machine vision to test and inspect parts for quality and relocating failed parts to a reject bin.

Automated finishing: Employing robotic cells for high-speed, safe and repeatable hot stamping tasks.

Recycling: Using robots to collect sprues and runners and place them into a granulator for recycling and reuse.

Wrapping, packaging and palletizing: Automating end-of-line procedures for speed, consistency and accuracy.

Key Components of an Automated Injection Molding System

A successful automated solution is a complete system. At JHFOSTER we evaluate your needs to integrate the right robot, control system and end-of-arm tooling.

Robotics: Robotics are the muscle in automated injection molding systems. The robot itself – whether a 6-axis, SCARA or collaborative robot – is selected based on your application’s payload, reach and speed requirements. The cost of a robot varies, but the focus should be less on cost and more on return on investment (ROI). JHFOSTER helps evaluate your application to find the most cost-effective solution, so it delivers rapid payback based on labor savings and increased throughput.

Control system (PLC): The PLC, or programmable logic controller, is the brain of the injection molding system. It’s an industrial computer that sequences and controls the robot, molding machine, conveyors and downstream equipment, ensuring they all communicate and work together safely, efficiently and effectively.

End-of-arm tooling (EAOT): These are the custom “hands” for the robot, and may include grippers, vacuum cups or vision-guided tools, that are designed specifically to handle your parts.

The Measurable Benefits of Full-Process Injection Molding Automation

When you automate both upstream and downstream operations, you gain measurable, high-value benefits that boost your bottom line.

Full-process injection molding automation benefits include:

Reduced labor costs: Automating repetitive, labor-intensive tasks offsets worker shortages and high costs. This frees your skilled workforce for more complex, high-value tasks.

Increased throughput: Automation is faster, more accurate and runs 24/7 without breaks, significantly increasing production output.

Faster lead times: By increasing throughput, you can accommodate shorter customer lead times, giving you a competitive advantage.

Higher quality parts: Automation provides precision and repeatability, ensuring that parts are processed the same way every time. This reduces mistakes, scrap and rework.

Reduced waste: Higher accuracy means less scrap and rework. Automation can also collect runners and sprues for recycling, increasing material savings.

Your Partner in Injection Molding Automation

JHFOSTER is more than a distributor. We are your expert integration partner. We have over eight decades of experience helping manufacturers in the upper Midwest work faster, smarter and more efficiently.

We provide end-to-end solutions. Our evaluate, design, integrate and support process means our team of experts will analyze your entire injection molding application – from upstream through downstream – to identify the best opportunities for optimization. We will design, build and support the custom automation solution that works best for you. Contact us today for a consultation on automating your injection molding application. Let our experts help you boost efficiency, throughput and quality so you get a competitive edge.