Achieve Unmatched Quality with Automated End-of-Line Vision Inspection

Eliminate end-of-line bottlenecks and ensure quality with an automated visual inspection solution. As your automation partner, JHFOSTER’s experts will engineer a custom visual inspection system that delivers high-speed, precise performance and puts an end to slow, error-prone manual inspections. Discover the right solution for your business by contacting us today for an evaluation.

What is Automated End-of-Line Vision Inspection?

End-of-line vision inspection is the final, critical quality check before product ships to ensure that every item meets exact specifications. Automated vision inspection systems use industrial cameras, specialized lighting, and intelligent software to perform non-contact, high-speed, precision checks.

Manual vs. Automated Vision Inspection

What’s the difference between manual and automated inspection? Manual inspection is a slow and variable process that relies on human eyesight, interpretation, and capabilities, making it error-prone and costly.

Automated end-of-line visual inspection provides reliability that surpasses human abilities and delivers consistent precision. Automating the process allows more throughput and prevents more defects from slipping through, increasing productivity, cutting costs, and ensuring customer safety and satisfaction.

Key Benefits of Automated Visual Inspection

When you partner with JHFOSTER for your automated visual inspection solution, you can expect:

- Unmatched precision and accuracy: Automation eliminates human fatigue and errors, providing consistent 100% inspection rates.

- Increased productivity and efficiency: Automated inspection systems can operate 24/7 at high speeds to remove end-of-line bottlenecks.

- Reduced costs: By minimizing costly scrap, rework, and product recalls, operating costs dramatically decrease.

- Enhanced reputation: Strong quality control prevents defective products from reaching consumers, protecting your brand reputation.

How Do Automated Visual Inspections Work?

Automated vision systems operate in three steps:

Step 1: Image Capture: Industrial cameras and specialized lighting capture images of the product.

Step 2: Image Processing: Special software processes the image and compares it to a defined “gold standard.”

Step 3: Decision/Action: A pass/fail signal is sent to the automation system for sorting, packing or rejection.

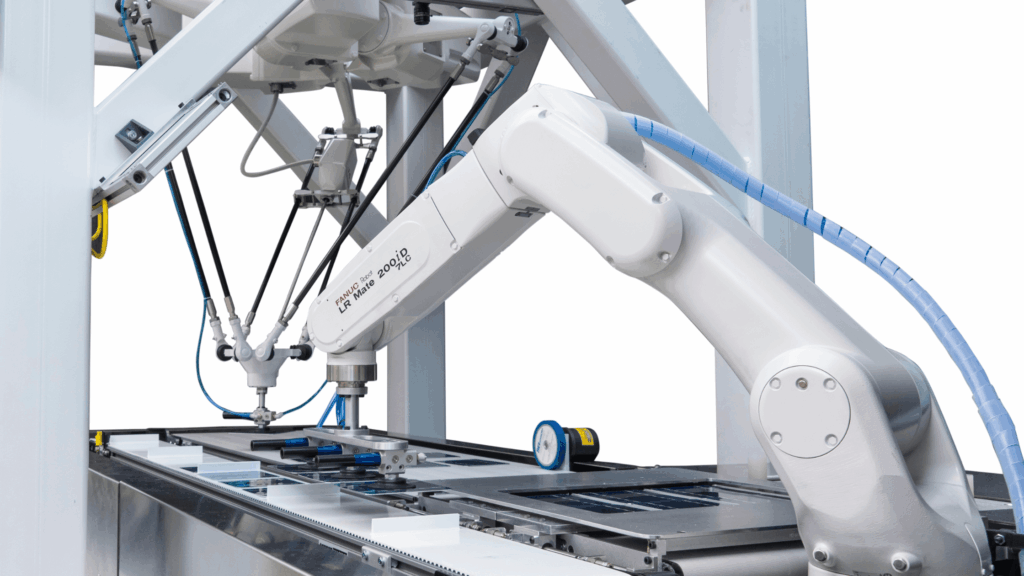

Automated vision inspection systems can be integrated with other automation solutions, like pick-and-place or machine tending collaborative robots to further boost speed and throughput.

Key Applications and Technology

Because automated visual inspection offers high-speed, reliable, precise, and objective quality checks, it is used in critical applications.

For example, automated optical inspection (AOI), a type of visual inspection, is often used for quality control on printed circuit boards (PCBs) and other complex assemblies because it offers high levels of precision.

Common applications for automated visual inspection technologies include:

- Barcode reading and verification.

- Part presence/absence and component positioning.

- Dimensional gauging (measurement).

- Surface defect detection.

- Label/print quality verification.

Your Partner in Automated Vision System Integration

Thanks to the high-speed, reliable, and accurate performance of automated vision inspection systems, you can expect a quick return on investment. While the cost of vision inspection systems varies based on complexity and hardware, the long-term savings of a faster, more precise inspection system easily offset the initial investment.

Rest assured, JHFOSTER’s expertise in designing a customized solution balances cost and necessary precision, providing you with the highest ROI.Browse machine vision systems at our sister company, Sensors Inc., to see how our systems can help you minimize defects and achieve higher quality. Start operating smarter and more efficiently by requesting a quote for a tailored vision system today.