Month: January 2023

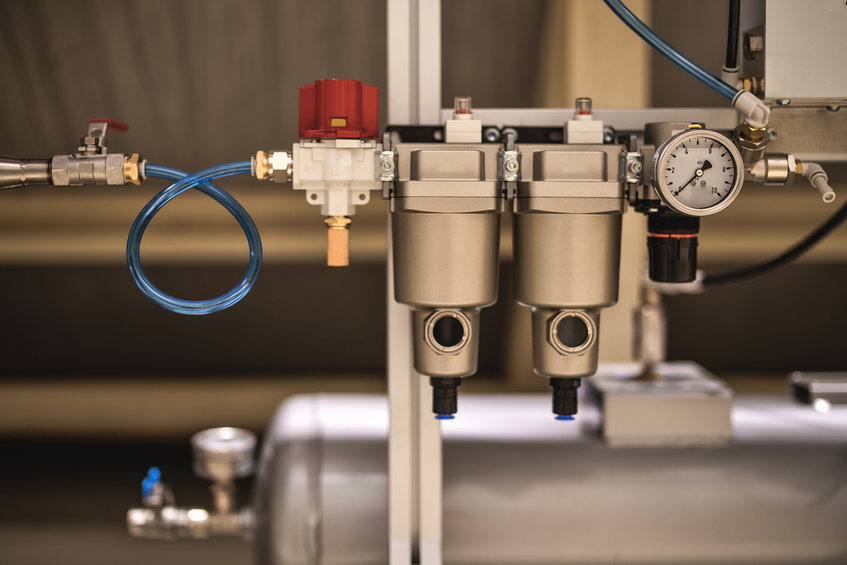

How to Tell When Your Compressed Air System Needs New Filters

Using clean dry air is beneficial for compressed air systems in many ways. It will reduce wear and tear and maintenance required for pneumatic tools, machines, and devices used in the manufacturing environment and help maintain product quality and consistency. You can reduce machine downtime by having the proper filtration system in place while also […]

How Can I Tell if My Air Compressor is Overheating? How Can I Prevent it?

Compressed air systems provide a critical energy source required for machinery and tools used in almost every industry. Unfortunately, the operating cost of air compressors can be quite high and if a business wants to remain competitive, proper maintenance of the compressed air equipment is required to assure reliable, efficient operation. When an air compressor […]

Understanding the Safety Functions of Collaborative Robots

As the use of collaborative robots continues to expand in industrial workplaces, humans are more frequently sharing space with cobots, as they’ve come to be nicknamed. While collaborative robots are considered “inherently safe” by design, there are understandably concerns regarding the safety of human operators working in close proximity to swift-moving industrial equipment. However, advances […]

What Should I Expect During an Air Energy Audit?

Compressed air systems are a necessity in most industrial facilities as they power many machines, tools and processes; however, they are notorious for consuming significant amounts of energy. As a matter of fact, the U.S. Department of Energy says that as much as 10% of all electricity generated in the United States is used by […]

How to Select the Best Industrial Robot for Manufacturing Applications

As robotic technology continues to develop, more manufacturers are applying industrial robots to automate tasks that are repetitive or dangerous for human workers or those that create bottlenecks within the facility. In these situations, robotic automation can increase productivity and efficiency, boost product quality and improve safety in a variety of manufacturing sectors. While the […]

Troubleshooting Motion Control Malfunctions

Motion control is a critical part of automated equipment and machinery found at industrial facilities. Malfunctions can result in downtime, wasted material, and safety issues. Quickly finding and fixing root causes will eliminate these losses and lead to reduced production delays. This blog will provide information on how to troubleshoot your motion control system so […]

How to Select a High-Quality Industrial Electric Actuator

With the rise of robotics and automation, electric linear actuators have become an essential component in the processing equipment, assembly machinery, machine tools and robots found in almost every industrial facility. Used to convert the rotary motion of an electric motor into linear motion, electric linear actuators enable industrial equipment to do its job; however, […]

Maximizing Air Compressor Efficiency Improves the Bottom Line

Because compressed air is widely used in industrial facilities, improving air compressor efficiency can create a competitive advantage as it will not only generate cost savings that will boost the bottom line, but it can also help your facility improve quality and achieve sustainability goals. While U.S. Department of Energy (DOE) statistics show that compressed […]

Regular Maintenance Ensures Functional and Efficient Pneumatic Systems

While pneumatic systems are often selected because they have a reputation for providing high reliability in tough industrial applications, that doesn’t mean that they don’t require a little TLC now and then. As a matter of fact, creating and adhering to a schedule of regular inspection and maintenance activities will ensure that your pneumatic systems […]