Month: August 2022

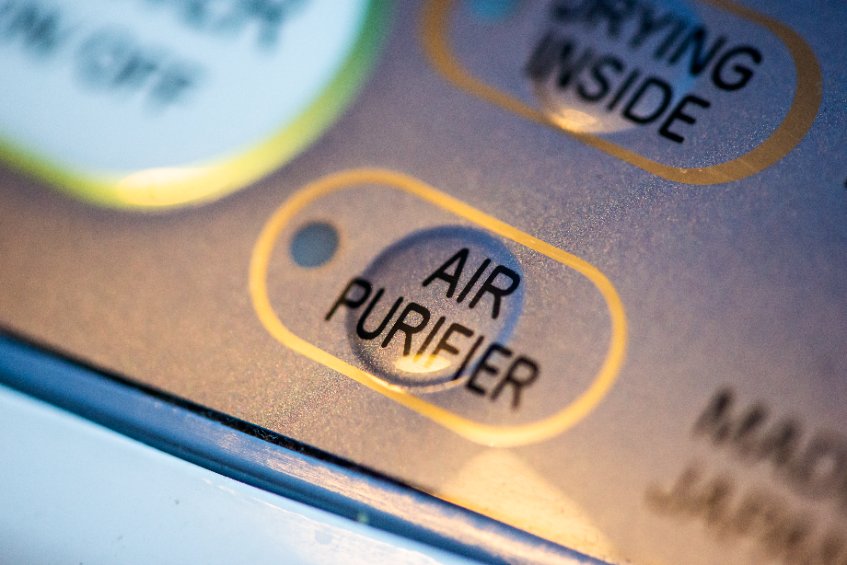

How to Pick the Perfect Industrial Air Compressor

From automotive to pharmaceutical, a lot of industries rely on air compressors. These machines push air into things to make them work. This can include powering up tools like jackhammers or staplers or supplying air pressure to industrial equipment. With so many on the market, it can be hard to know which one is right […]

The Differences Between Collaborative and Industrial Robots

As the world of robotics continues to become a fast-growing industry, so does the way in which we use them. Collaborative robots and industrial robots are quickly becoming staples in modern factories and businesses. In this article, we will explore the significant differences between cobots and traditional industrial robots. We will also discuss the benefits […]

Pulsed Air-Piloted Valves or Direct-Acting? When OEMs Only Go With What They Know, They May Be Missing Out

By Tom Voth, product marketing manager: pneumatic machine safety and electronic proportional valves, Emerson OEMs are always seeking solutions that reduce machine complexities and minimize operator intervention, and proportional valves are one of many important technologies involved in achieving these design goals. Though several proportional valve designs exist, pulsed air-piloted and direct-acting are the most […]

Help! I Think I Need a Larger Industrial Air Compressor!

Uh-oh. Suddenly there seem to be more operator reports stating that tasks can’t be completed because the air-powered equipment isn’t supplying enough pressure to get the job done. When these problems arise and your maintenance team has ensured that it’s not related to clogged filters or other issues that can cause the air compressor to […]

Accessorizing Your Air Compressor to Improve Efficiency

Air compressors may come with all the essential accessories, or…they may not. In other cases, an air compressor may not be working the way it should be because an accessory is in disrepair, in need of a replacement or was never added to the system. Either way, your compressed air system should be supported by […]

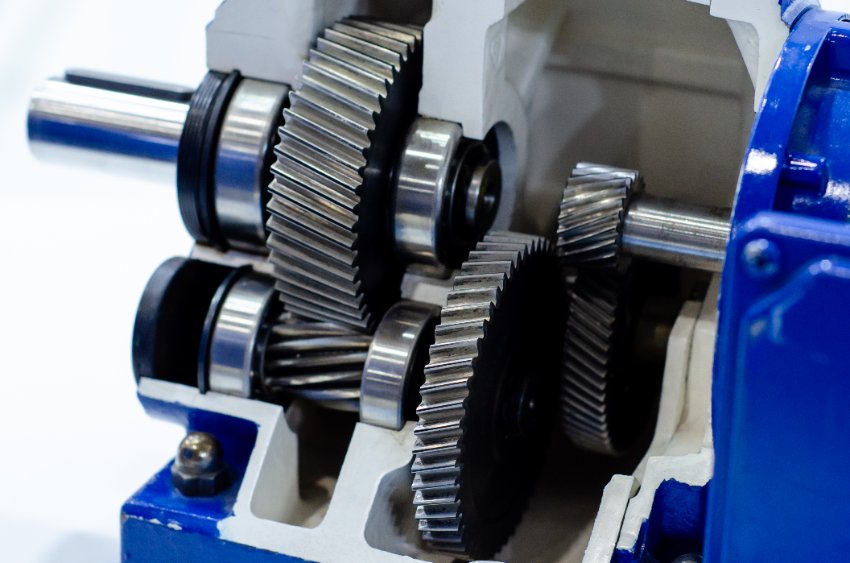

Proper Mounting Helps Prevent Gearbox Failure

Essential to providing speed and torque control to the motors of almost all industrial machinery, gearboxes can be found in applications ranging from machine tools to conveyor belts to industrial robots to heavy-duty mining equipment. Because they are durable mechanical devices designed to withstand the high temperatures, pressures and extreme conditions found in industrial environments, […]

Using ISO 8573-1:2010 to Ensure Compressed Air Purity Levels

Often called “the fourth utility,” compressed air systems are used throughout the manufacturing industry and serve many functions within a facility. They drive pneumatic equipment used on items such as conveyors that move product from place to place; run tools, machines and other equipment essential to production and power packaging systems that keep finished product […]

Regularly Performing Compressed Air Energy Audits Can Boost the Bottom Line

A focus on sustainability coupled with the rising cost of electricity has made energy efficiency a top priority for industry. Unfortunately, improperly designed and maintained compressed air systems can be major energy hogs. As a matter of fact, the U.S. Department of Energy’s Compressed Air Challenge found that in a typical industrial facility, approximately 10% […]

Five Common Issues Found in Compressed Air Systems

Compressed air systems are an essential part of many industrial and commercial settings. They provide the power to run tools, equipment, and machines. According to the United States Department of Energy, compressed air systems alone consume about 10% of industrial electricity. However, these systems can be plagued by several common issues. If left ignored, these […]