The Automated Flex Feeder System Advantages over Bowl Feeders

Faced with mounting pressure to improve efficiency, accuracy and quality, many manufacturers employ automated feeding systems to further boost throughput and reduce the burden on manual laborers. Automated feeding systems enhance productivity because they quickly separate bulk parts and place them in the proper orientation so they are consistently fed onto an assembly or production line. Until recently, bowl feeders were the go-to solution, but advances in automation, robotics and vision systems make a newer technology – automated flexible feeder systems – a superior choice in applications that must further maximize production efficiency and/or require flexibility for variations in parts.

This blog will explore the differences between bowl and flexible feeders, introduce one of the most versatile automated flexible feeders on the market and highlight 10 advantages of flexible feeders over bowl feeders.

Bowl Feeders vs. Flexible Feeders

Traditional bowl feeders typically rely on mechanical vibration or centrifugal force to sort and supply parts and components to a production line. They are well suited to applications in which a high volume of a single part must be supplied to a fixed production line; however, bowl feeders are usually designed to be part specific, making it difficult to convert them to feed a different product. For manufacturers that run mixed or variable production, it is often necessary to have several different bowl feeders available.

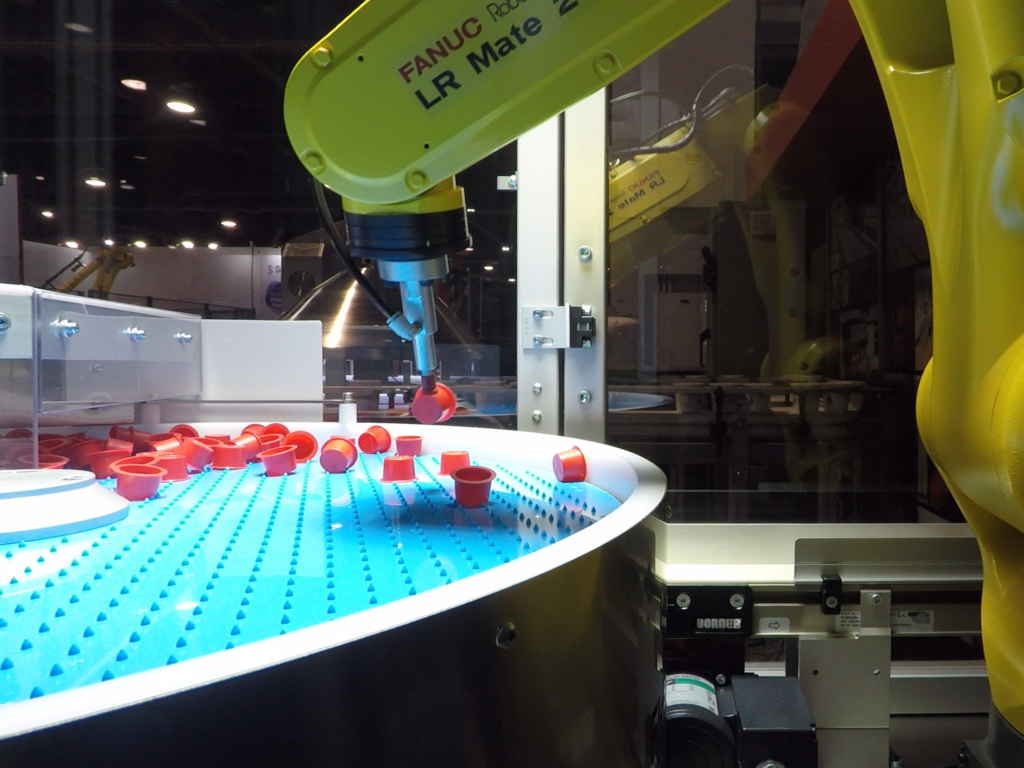

In comparison, an automated flexible feeding system consists of the feeder, a vision system and a robot. In action, parts from a hopper are dropped onto the feeder surface where a robot equipped with a vision system identifies parts that are properly oriented and then uses pick and place functionality to grab and supply them to the production line with speed, accuracy and consistency. Additionally, the ability to pre-program an automated feeding system for multiple parts permits many different components to be run on the same feeder.

A prime example of this technology is DevLink’s AFFS Automated Flexible Feeder System. It consists of a flexible feeder bowl, an integrated vision system and a robot, which seamlessly work together to easily align and feed parts, regardless of their shape, in assembly and packaging applications. Using this automated system, parts are dropped onto a rotating disc where they are oriented and aligned for robotic pick and place. The system is compatible with most parts, even silicone, and multiple programs can be loaded to the system to permit simplified switching between parts. Pairing with FANUC robots, the AFFS can feed multiple types of parts on the same feeder – saving manufacturers valuable real estate on the assembly floor, while providing both efficiency and the agility to handle a variety of parts.

10 Advantages of Automated Flexible Feeding Systems

With an integrated vision system and the ability to pre-program for multiple types of parts, automated flexible feeding systems like the AFFS from DevLinks provide a lot of advantages over traditional bowl feeders, including:

| 1 | The flexibility to process more than one specific part or component on the same feeder, making automated flexible feeder systems suitable for mixed or variable production facilities. |

| 2 | The ability to identify parts that are correctly oriented enables flexible feeder systems to increase accuracy, consistency and efficiency. |

| 3 | Pre-programming for multiple parts allows operators to introduce product changeovers with the touch of a button, reducing costs and labor time, while further boosting productivity, throughput and efficiency |

| 4 | The integrated vision system can help identify defective parts, which improves quality control efforts. |

| 5 | Unlike traditional feeder systems the AFFS is excellent at feeding silicone and rubber parts |

| 6 | The vision system can identify parts that are properly oriented, not overlapping and have enough space around them to be picked with accuracy, enabling the system to pick without error. |

| 7 | The ability to streamline assembly, even if a vendor delivers unorganized parts. |

| 8 | Because only one system is needed for multiple products in a mixed or variable production facility, floor space requirements are reduced, as are costs associated with purchasing several feeding systems to accommodate mixed or changing production. |

| 9 | The arrangement of the system prevents jams, which are common with traditional bowl feeders, helping to decrease downtime and improve throughput. |

| 10 | Less noise is created with flexible feeding systems than with traditional vibratory and centrifugal bowl type feeders |

Is an Automated Flexible Feeding System Right for You?

Because automated flexible feeding systems like the AFFS Automated Flexible Feeder System from DevLinks can align and feed parts, regardless of shape, size or material, without error and with high levels of efficiency, many manufacturers are opting to employ them over traditional bowl feeders, but are they right for your facility?

The answer is likely “yes,” if:

- You have limited floor space.

- You change parts frequently for assembly or production.

- You feed silicone parts.

- Your vendors deliver unorganized parts for assembly or production.

For more information on how the advantages of flexible feeders like the DevLinks AFFS Automated Flex Feeder System can streamline your assembly or production line, please contact a representative at JHFOSTER.