Air System Filters, Regulators, and Lubricators

Air leaving a compressor is hot, dirty, and wet which can damage and shorten the life of downstream equipment, such as valves and cylinders. Before air can be used it needs to be filtered and regulated. Lubricators are available if the equipment requires lubrication. JHFOSTER distributes a full line of compressed air filters, regulators and lubricators for keeping industrial compressed air clean and dry with products such as Arrow Pneumatics, AVENTICS, Beach, Bimba MFD, Parker-Domnick Hunter and ASCO. Contact us today at 855.688.0065 or email and we can help you find the right pneumatic filter, regulator or lubricator for your equipment needs.

Filters Your Air Compressor Needs

The air entering an air compressor is often hot, damp, and full of contaminants from the surroundings. A high-quality air filter is necessary to keep out particulates, dust, oil, and oil in the air from damaging downstream equipment such as valves and cylinders, wearing down parts and causing blockages.

You can help prolong the lifespan of your by using a high-quality air filtration system. Apart from ensuring that contaminants do not reach your downstream machines.

Durable and High-Performance Regulators

A malfunctioning or broken regulator results in inconsistent airflow and pressure. Your equipment could be subjected to the wrong PSI, resulting in poor performance and eventual damage.

Recommended Products and Solutions

Instead of individual solutions, a filter, regulator, and lubricator treatment accessory can be equipped into your air system. It’s a complete solution and can be easily adjusted according to the filtration and air pressure your machine needs. The air gets treated while regulating the pressure and the flow direction.

The lubricator feature also ensures that specialized lubricant is applied to your machine, reducing equipment friction. This also helps improve the speed performance of your machine.

Contact Us to Find the Air System Filter and Regulator You Need

Depending on its make and model, your machine might need a specific air filter, regulator, and lubricator accessory. JHFOSTER has an extensive range of compressed air system filters and regulators suitable for various equipment.

Call our experienced evaluators today to get a quote and learn more about the best accessories for your compressed air system. You may also reach out to us via our online form to request more information about our air system accessories inventory.

Literature Library

Looking for additional information? Check out JHFOSTER’s Automation Library.

TECHNOLOGY

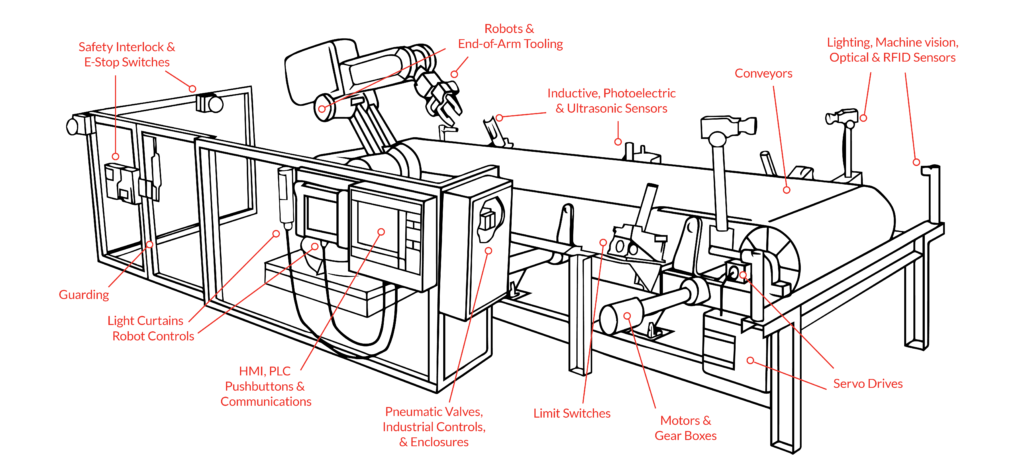

Motion & Mechatronics

- Rotary/Linear Motion

- Sizing/Consultation

- Motors/Drives/Control

- Robots

- Conveyors

Sensors & ID

- Presence

- Inductive/Capacitive

- RFID/Bar Code

- Safety

Data

- Networks (LAN/WAN)

- HMI/Web Panel

- Remote Access/Monitor

PRECISION MACHINING

- Horizontal Millin – 5 axis

- Vertical Milling = 5 axis

- Turning (up to 14″)

- Swiss Turning (approximately 3 – 20 mm)

- CAD Solidworks

- Gibbs & Surfcam

ELECTRO-MECHANICAL ASSEMBLY

- UL508A Certified Panel Shop

- Control Panel Build

- Enclosures

- Value Added Sub Assemblies: Pneumatic, Mechanical, Electrical, Build to Print

- Horizontal Millin – 5 axis

- Vertical Milling = 5 axis

- Turning (up to 14″)

- Swiss Turning (approvximately 3 – 20 mm)

- CAD Solidworks

- Gibbs & Surfcam

Frequently Asked Questions

It’s crucial to ensure that the compressed air in your pneumatic system isn’t wasted. By using a pressure regulator, you’ll be able to control and maintain a constant output despite varying input pressures and output flows.

It depends on the specific product that you own. Modern pneumatic products typically have seals made from Nitrile, with some seal manufacturers incorporating Teflon into their Nitrile material to further reduce friction. This means that lubricators are not necessary for these products.

However, a few pneumatic components still require internal lubrication to ensure smooth performance.

You have to determine what kind of maintenance your product needs and if it requires a lubricator in the first place. After that, you must only apply the lubricator to the device that requires it: you don’t need to lubricate the entire system.

Yes. As with any add-on to your pneumatic system, air filters need regular checks and maintenance to ensure that they’re working correctly. Filter maintenance is essential because the filter element traps the impurities and substrates that would have otherwise gone into the machine.

Eventually, that filter will reach its full capacity, and air will no longer easily pass through it, causing airflow and pressure drop issues. It also causes poor air quality. In turn, this leads to wasted energy, rust developing on pneumatic tools, and lubricant failure.

Replacing the filter prevents all these problems and ensures that air quality remains optimal.

There are three main types of pneumatic air filters: vapor, particulate, and coalescing. Coalescing filters remove water and aerosols. Vapor filters eliminate compressor lubricant vapors that would otherwise have ended up in the coalescing filter. Meanwhile, dry particulate filters remove particles.

Installing and replacing the filter element depends mainly on your pneumatic device’s needs. Some machines may also require more than one type of filter. It’s recommended to consult with equipment specialists or see the manufacturer’s guide to determine the appropriate type of filter needed.