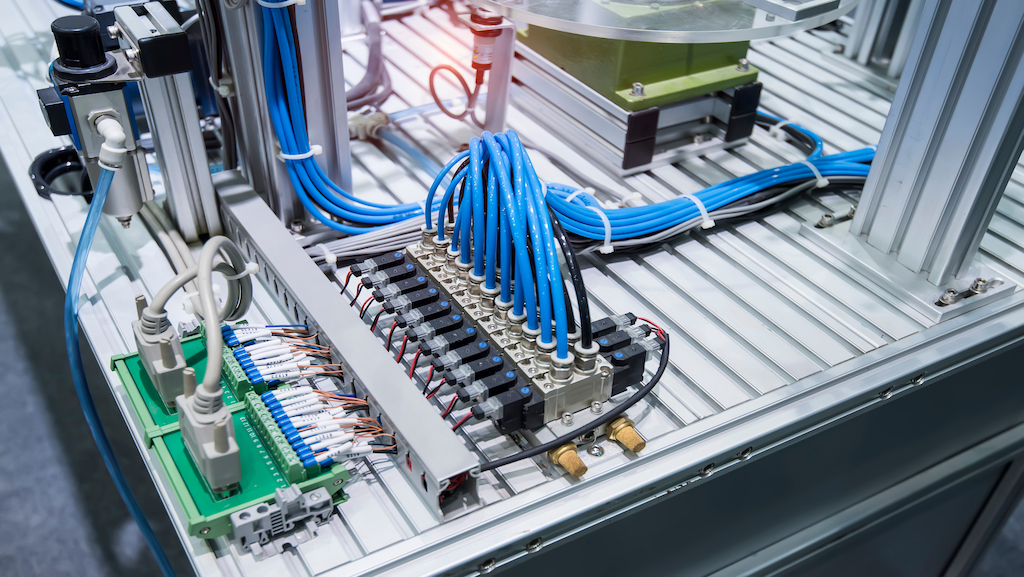

Pneumatic Fittings

Pneumatic fittings are vital components of any pneumatic system. They are the link between components, hoses, tubes, accessories, and other parts that need to be joined together.

Why You Need Pneumatic Fittings

For pneumatic equipment and machinery, the appropriate fittings create airtight seals. This is crucial for a pneumatic machine to function correctly. Incompatible or loose fittings can result in compressed air leaking. The machine won’t have the required pressure to operate correctly.

Recommended Products and Solutions

Push-in connectors or push-to-connect fittings deliver ease of use combined with secure and reliable mounting. They are made of premium, durable materials, such as nickel, brass, and stainless steel, which ensure that the fittings are highly resistant to corrosion.

Push-to-connect fittings have user-friendly release rings. Users can easily and quickly release tubes from connections, saving time and effort. They also have more surface area for grip and handling.

Along with ease of attachment and release, the push-to-connect fittings feature optimum seals through captive O-rings. These seals remain airtight and withstand high pressures, ensuring peak performance for pneumatic machines.

Push-to-connect fittings come in different styles and sizes, ensuring that there’s a fitting for every machine and connector. All of these are industrial-grade fittings, capable of withstanding numerous connections and releases, allowing for easy reconfiguration of your pneumatic systems for a long time.

Contact JHFOSTER for Top-Notch Pneumatic Fittings

Finding compatible pneumatic fittings for your equipment requires careful evaluation of the pressure and flow requirements. Reach out to our team for guidance on choosing the right fittings for your equipment. You may also fill out our online form to request more information about the fittings in our inventory.

Literature Library

Looking for additional information? Check out JHFOSTER’s Automation Library.

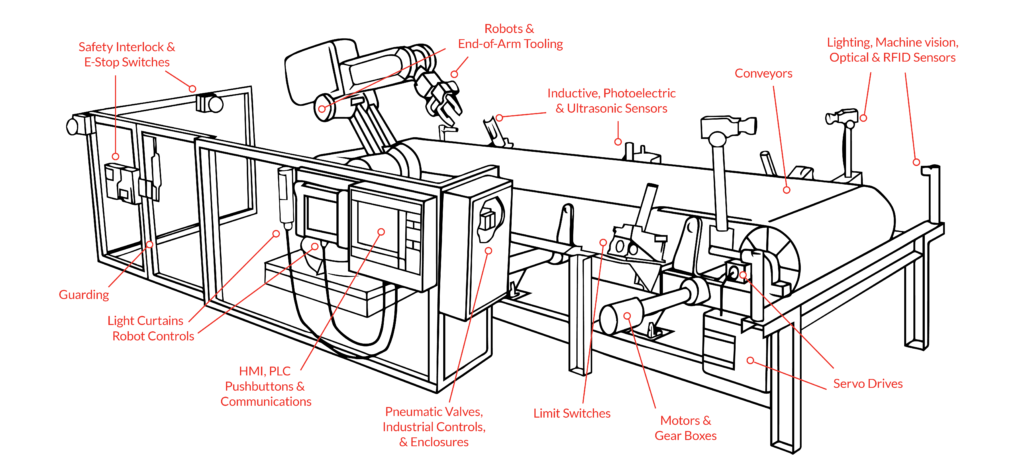

TECHNOLOGY

Motion & Mechatronics

- Rotary/Linear Motion

- Sizing/Consultation

- Motors/Drives/Control

- Robots

- Conveyors

Sensors & ID

- Presence

- Inductive/Capacitive

- RFID/Bar Code

- Safety

Data

- Networks (LAN/WAN)

- HMI/Web Panel

- Remote Access/Monitor

PRECISION MACHINING

- Horizontal Millin – 5 axis

- Vertical Milling = 5 axis

- Turning (up to 14″)

- Swiss Turning (approximately 3 – 20 mm)

- CAD Solidworks

- Gibbs & Surfcam

ELECTRO-MECHANICAL ASSEMBLY

- UL508A Certified Panel Shop

- Control Panel Build

- Enclosures

- Value Added Sub Assemblies: Pneumatic, Mechanical, Electrical, Build to Print

- Horizontal Millin – 5 axis

- Vertical Milling = 5 axis

- Turning (up to 14″)

- Swiss Turning (approvximately 3 – 20 mm)

- CAD Solidworks

- Gibbs & Surfcam

Frequently Asked Questions

Consider your machine’s:

- Working pressure

- Working temperature

- Working environment.

The fitting needs to be compatible with all the factors above so that the machine can work efficiently and without the risk of leaks. If you need help finding the correct fitting for your machine’s specifications, our specialists can advise you.

The pneumatic fitting size will depend on the vessels it will connect to. The inside and outside diameter of the tubes, hoses, and pipes your machine uses should be measured to find the most appropriate fitting.