Lubricated or Oil-Free Compressors?

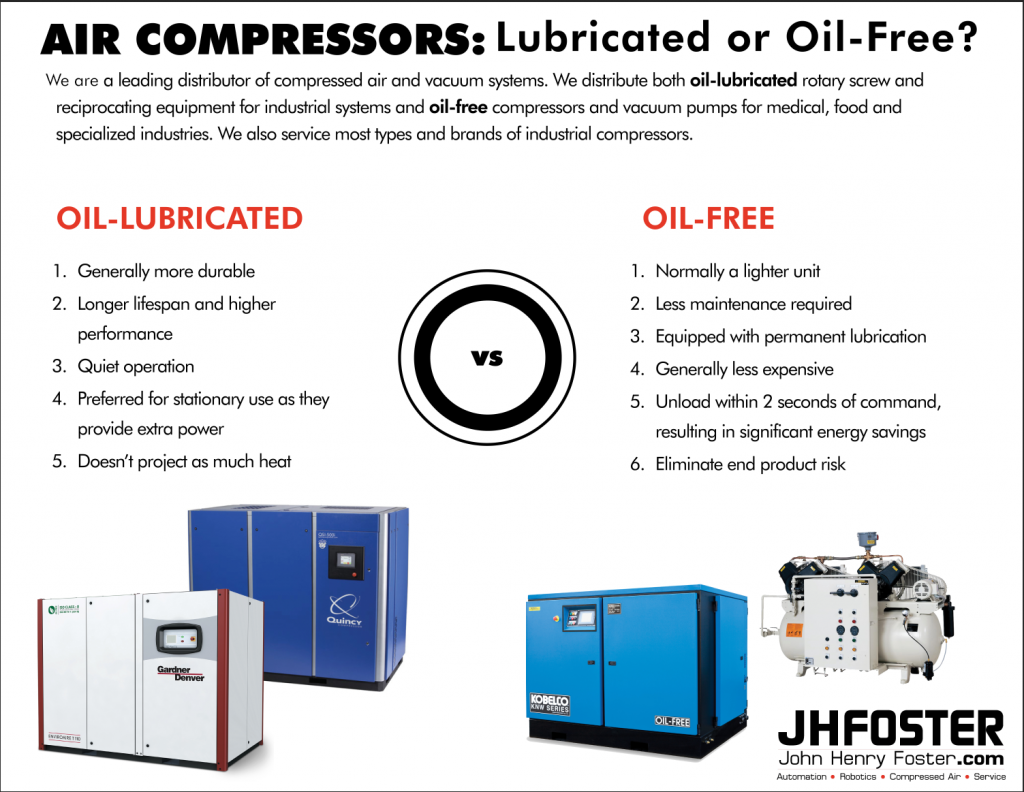

When it comes to selecting the best industrial compressor, businesses need to take into consideration what application the compressor will be used for. The best compressor for the job is generally application specific and will depend on what industry your company is in. Often, the level of air purity decides whether you need an Oil-Lubricated or Oil-Free compressor.

Oil-Flooded Compressors

Oil-flooded compressors are generally used in applications where contamination isn’t necessarily an issue. They are also used when businesses prefer to get a bit more longevity out of their machines.

Due to their oil-free status, parts tend to wear out faster in oil-free compressors because oil isn’t lubricating moving parts. Therefore, the compressor system itself will have a slightly shorter life than oil-flooded systems.

Oil-Free Compressors

Then, there is the oil-free compressor. These compressors are for industries that need a clean, pure compressor to compress air. Also, keep in mind, the higher the quality of the compressed air, the better the product and the lower the cost to produce it.

Oil-free compressors are often used in the medical field, in the food production industry, and in beverage production industries. This is due to the level of purity that oil-free compressors offer.

Analyze Your Options

It’s pretty incredible that man has found a way to take ambient air and transform it in a way that powers manufacturing plants. Further, compressed air cleans hospital room air, automates processes and is used as an everyday convenience.

With that said, do you know which type of compressor would best meet your demand? Oil-lubricated or oil-free? Unfortunately, there aren’t a whole lot of guidelines that tell you which compressor type to choose.

However, there are a few strategies that can help you determine which compressor is right for your company. First, you need to identify if there are any industrial codes or certifications necessary. In addition, identify the benefits of each unit and your job requirements. (See above in our graphic). These factors will help you determine the best compressor for your business.

Finally, these are the different types of oil-lubricated and oil-free compressors we distribute at JHFOSTER.

Oil-Lubricated Compressors

- Gardner Denver (CompAir): Rotary screw: 5-500 HP, Reciprocating: ½ – 30 HP

- Hydrovane: Rotary vane: 2-60 HP

- Quincy: Rotary screw/reciprocating: ½ – 350 HP

- Sauer Compressors USA: Reciprocating 2-4 stage high pressure compressors and boosters 100-6000 PSIG

Oil-Free Compressors

- Gardner Denver (CompAir): Water-sealed: 20 HP – 150 HP, Rotary screw: 100 HP – 400 HP, Reciprocating: 3/4 HP – 15 HP, Scroll: 2 HP – 40 HP

- Kobelco: Rotary screw: 20 HP – 500 HP

- Powerex: Super quiet scroll and reciprocating: 3 HP – 40 HP

- Quincy: Scroll: 2 HP – 30 HP

- Thomas: Diaphragm, rotary vane, linear, articulating piston, WOB-L piston

VIEW OUR FULL OIL-FREE PRODUCT LINE

Contact Us

Our team of experts are positioned to support your productivity and efficiency needs with our versatile products and services. Please contact us today at 651.452.8452 or email us to learn more about our line of air compressors, vacuum equipment, engineering and design capabilities, or any of our product offerings.