Your Ultimate Guide to Medical-grade Air Compressors

The medical industry is no doubt busier than ever. The effects of COVID-19 have changed the medical industry forever. Efficiency, sterility, and cleanliness are at an all-time high of importance. Clinics are trying to ensure that their patients are kept healthy and that nothing gets in their way of healing. The question is: how can you ensure this while powering medical equipment with air compressors? The answer is medical-grade air compressors like the oil-free variety.

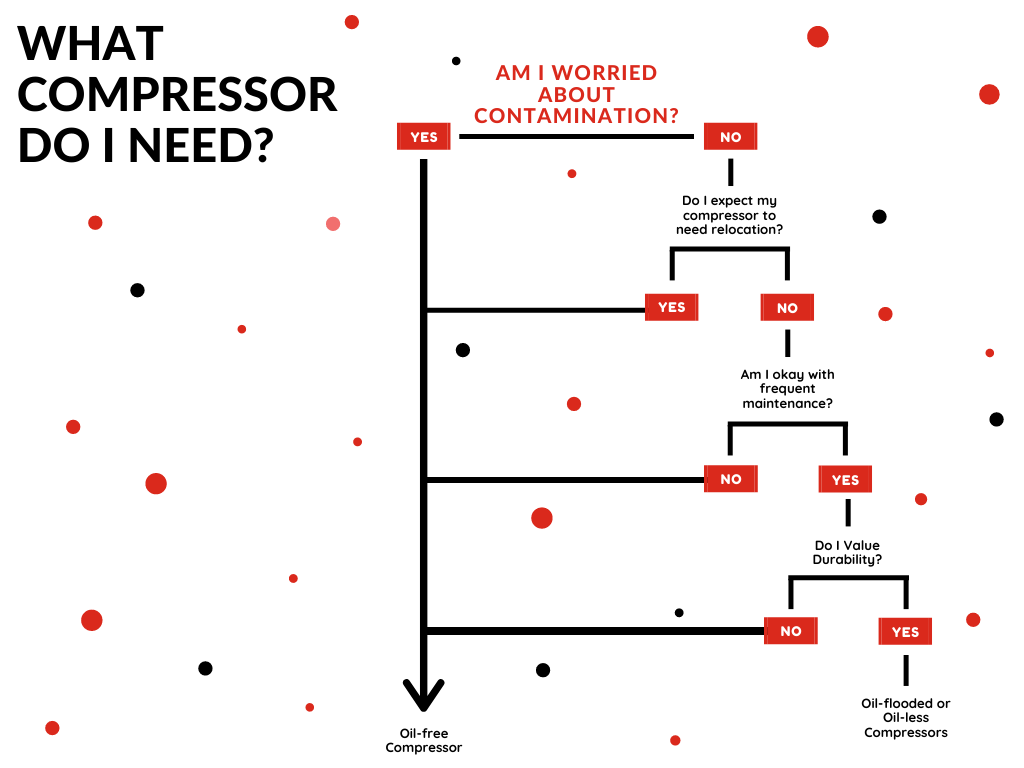

Identifying the Right Air Compressor

Well, there is a bottom line here. Oil-flooded and oil-less compressors risk contamination. There’s just no way around it. In some applications, this may not matter as much. However, when an air compressor is housed in a medical clinic, you do not want to risk any chance of contamination anywhere onsite. Even when you are dealing with powering medical devices, you can’t take any shortcuts or risks.

This is why the medical industry has turned specifically to medical air compressors in the form of the oil-free grade.

What types of applications can oil-free compressors power?

- Patient Breathing

- Blood Analyzing

- Powering Hand-held Medical Tools

- Air Filtration in the Duct System

- Sterilization of Equipment

What Happens When My Air Compressor Experiences Breakdown?

When your compressor breaks down, any application it is being used for ceases to operate unless you have a backup system. Below we are going to list our suggestions for handling breakdowns and precautions to take to make sure it doesn’t happen in the first place.

Perform Regular Service and Maintenance

Just like your car, your compressor will need continual service and maintenance. Your car likely needs a routine change of wiper blades once they wear down. Your compressor may need new parts, too!

Make sure your maintenance team has schedules created, outlining when they need to service air compressors. You can also keep a backup system on standby to step in for any malfunctions that occur from missed maintenance.

Make Sure You Have a Maintenance Crew

That leads us to the next point. Make sure you have a maintenance crew! This may be a general maintenance staff member that has experience with air compressors. Make sure that your maintenance staff member or team stays up to date on best maintenance practices for medical-grade compressors.

However, what if you don’t have a staff member or team dedicated to maintaining and servicing your compressor? If this is the case, make sure you have a service subscription with a company that focuses on servicing air compressors. Many companies have 24-hour Emergency Service that will help ensure your compressor stays running. JHFOSTER is one such company that offers this service.

You will also want to make sure that any maintenance performed is done by someone with an ASSE 6040 certification. This ensures that the person working on your system is doing so up to medical standards. Our technicians are all certified, so if you contact our service techs, you can be assured they know their stuff!

Take Extra Precautions in the Summer

The sun takes its toll on people and compressors alike. In the summer, heat can cause unexpected breakdowns and part wear-outs in your compressor system if it isn’t properly cared for.

We have a guide on how to prevent summer breakdowns. However, to summarize what you need to do:

- Home your compressor in a ventilated room

- Perform checkups on your dryer

- Change worn out parts

- Dust electrical components

- Regularly service your compressor

Contact Us

Do you have more questions on medical-grade air compressors? Contact our specialists by email or phone to ask them your questions!