What is a 2-Stage Air Compressor?

Powering your pneumatic tools and production equipment efficiently and reliably depends upon choosing the right air compressor for your application. If you’ve been exploring the options, you’ve likely come across 2-stage air compressors. This blog will explain the technology, how it works and why a 2-stage compressor might be the ideal solution for your demanding application.

How a 2-Stage Air Compressor Works

Also known as two-stage air compressors, 2-stage compressors compress air in two steps to generate higher pressures with greater efficiency than single-stage air compressors.

Two-stage compressors work as follows:

Step 1: First Stage Compression: In 2-stage piston compressors, ambient air is drawn through the air inlet into the first, larger cylinder where a piston compresses it to an intermediate pressure. In 2-stage rotary compressors, ambient air is drawn into a chamber and compressed to an intermediate pressure by the first set of synchronized rotors.

Step 2: Intercooling: In both piston and rotary 2-stage models, compressed air is sent through an intercooler after the first compression stage is complete. This cooling process reduces the temperature of the compressed air prior to entering the 2nd stage.

Step 3: Second Stage Compression: In a 2-stage piston compressor, the cooled, partially compressed air enters a second, smaller cylinder for additional compression. In a 2-stage rotary compressor, a second set of high-pressure, synchronized rotors further compresses the air. In both compressor types, the second stage compresses the air to its final pressure before it is moved to the receiver tank.

It may be helpful to think of the operation of a 2-stage air compressor like a two-person relay race where the first runner hands off midway to a fresh, second runner in order to finish the race stronger and faster.

2-Stage vs. 1-Stage Air Compressors: What’s the Difference?

The main difference between single-stage and two-stage compressors is the number of stages involved in the compression process. In single-stage models, intake air is compressed once before the compressed air is moved to the receiver tank. Two-stage air compressors subject the air to two stages of compression at increasing pressures with cooling in between each stage. This enables greater pressures, airflow and more energy efficient operation.

The following table compares the two technologies.

| Feature | Single-Stage Compressor | Two-Stage Compressor |

| Maximum Pressure (PSI) | Typically up to 135 PSI in pistons and 150psi in rotary screws. | Typically 175 PSI or higher in pistons and 150psi or higher for rotary screw. |

| Best For | Piston: Intermittent use, smaller tools, workshops. Industrial rotary screw: Continuous duty applications. | Continuous-duty applications for piston or rotary screw compressors supplying demanding industrial tools and equipment |

| Efficiency | Efficient for lower-pressure requirements | More energy efficient when generating higher pressures |

| Operation | Single stage pistons are commonly used for small, light duty applications and single stage rotary screws for large heavy duty industrial applications. | Less heat generated and work required, due to intercooling & multistage technology |

| Durability | Simple, less costly technology, very reliable when properly applied. | Two-stage pistons are designed to provide long service life in heavy-duty, industrial applications. Two-stage rotaries are commonly recommended for improved efficiency or high-pressure applications. |

What about Multi-Stage Compressors?

Air compressors are also available in 3-, 4- and 5-stage models for specialty applications that demand ultra-high pressures (typically around 2000 PSI or more), such as medical oxygen, SCUBA tanks or sensitive or precision industrial applications.

Why Your Operation Might Benefit from a 2-Stage Compressor

There are several benefits to using a 2-stage air compressor, including:

Higher, more consistent air pressure: Two-stage compressors can deliver pressures of 175 PSI to power demanding pneumatic tools and equipment without sacrificing performance or efficiency.

Greater energy efficiency: The intercooling process between the two compression stages reduces the load on the air compressor, making the generation of higher pressures less energy intensive and reducing long-term utility expenses.

Common Applications for 2-Stage piston Air Compressors

Two-stage piston air compressors are ideal when higher pressures and continuous operation are requirements. Common applications include:

Automotive: Two-stage piston compressors are used to power demanding pneumatic tools, inflate truck tires or provide the continuous pressure required for spray painting and surface finishing.

Small manufacturing operations: Metal fabrication, machining and woodworking shops.

Common Applications for 2-Stage rotary screw Air Compressors

General manufacturing: Applications such as driving pneumatic assembly line machinery and material handling equipment may benefit from the efficiency of large, 2-stage air compressors.

Aerospace and defense manufacturing: Two-stage compressors may be used in large assembly equipment and precision machining of components operations.

Food and beverage processing: Two-stage air compressors used in large factories can efficiently and effectively provide air for powering mixers, injectors, sealing and packaging machinery and bottling lines.

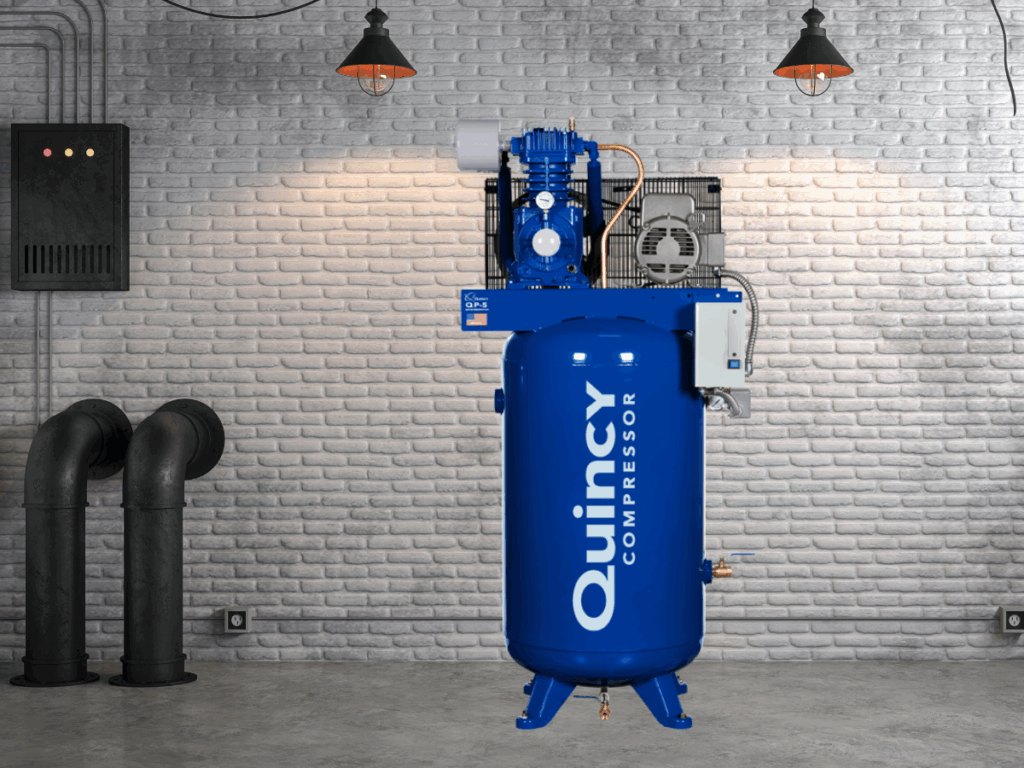

How to Identify a 2-Stage Compressor

Two-stage piston compressors will have two different-sized cylinders with the first cylinder being larger than the second with an intercooler between the two cylinders. Two-stage rotary compressors include two airends with an intercooler between them.

Find the Most Efficient and Reliable Solution for Your Needs

For applications that require constant high pressures, flows and continuous operation, a 2-stage air compressor will provide high levels of performance in an energy efficient manner. In operations with a fluctuating air demand, a variable speed drive (VSD) single or two stage compressor might offer greater energy savings.

However, the best way to determine whether a 1-stage, 2-stage or VSD compressor will be the ideal solution for your application is with a professional assessment of your unique operation. An assessment helps prevent the purchase of equipment that is not a good fit for the application or is over- or undersized, which can lead to premature failure or poor performance.

Your Partner in Compressed Air Systems

As your partner in designing, integrating and supporting your compressed air system, our experts can evaluate your needs to ensure that you get the air compression system that provides the best performance at the greatest efficiency. Contact an air compression expert or request a system evaluation today.