Boost Productivity and Efficiency with Robotic Machine Tending

Manufacturers are under pressure to increase productivity and throughput. Automation provides a powerful solution because it increases efficiency and frees skilled workers to focus on more complex, value-added tasks. Robotic machine tending, which automates repetitive, time-consuming tasks, can help your operation reach production targets by overcoming labor shortages and production bottlenecks.

What is Robotic Machine Tending?

Machine tending is the process of loading raw materials into a machine, unloading the finished parts after the cycle and restarting the process from the beginning. When performed manually, machine tending is a repetitive, physically demanding and time-consuming task.

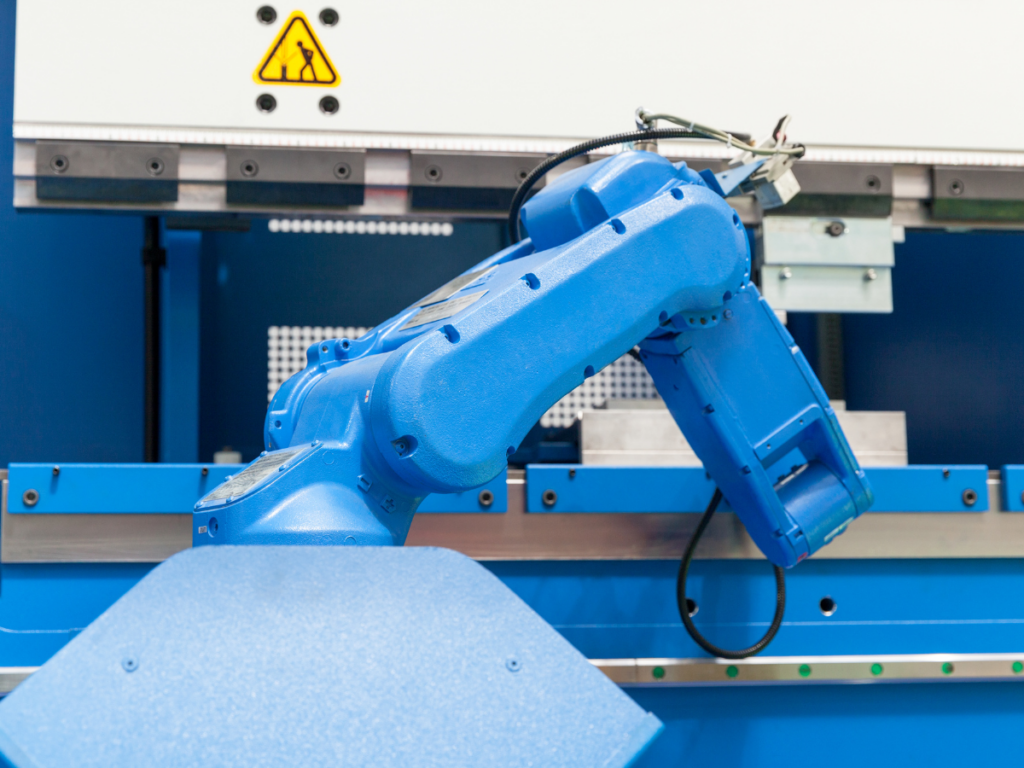

Robotic machine tending provides an advanced automation solution in which a robot performs the required tasks. These robotic systems can communicate with process machinery and can be programmed to perform multiple functions in a single, seamless application with superior precision and flexibility.

Tasks Machine Tending Robots Can Perform

- Picking raw materials and precisely placing them into machines

- Operating machine doors

- Removing finished parts

- Performing post-processing tasks like cleaning, deburring or polishing

- Changing end-of-arm tooling.

Discover JHFOSTER’S robotic machine tending solutions.

4 Key Benefits of Automating Your Machine Tending Process

Automating machine tending can help you reach your production goals and will directly benefit the company’s bottom line.

Benefit 1: Increased Throughput and Efficiency

Robots operate faster than human workers and can run 24/7 without breaks, shift changes or fatigue. This improves efficiency, eliminates human-induced bottlenecks and significantly increases throughput.

Benefit 2: Improved Product Quality and Consistency

Robots offer unparalleled accuracy and repeatability, ensuring parts will be loaded the same way every time. This minimizes issues related to human error, resulting in less waste and rework and providing higher quality products.

Benefit 3: Enhanced Workplace Safety

Machine tending is not only dull, but machine hazards and the repetitive bending, lifting and twisting motions associated with machine tending can cause workplace injuries. Automating machine tending tasks removes workers from potentially hazardous machinery and eliminates repetitive motion injuries.

Benefit 4: Reduced Operational Costs

By increasing efficiency, reducing scrap and waste and minimizing workplace injuries, robotic machine tending allows businesses to lower operational expenses. It also addresses the high costs associated with sourcing, training and retaining labor for non-value-added manual jobs.

Common Applications for Machine Tending Automation

While machine tending is most common in CNC machine shops, its applications are widespread across many industries, including automotive, aerospace, electronics, medical and general manufacturing.

Primary applications include:

- CNC machine tending (mills, lathes, presses)

- Injection and compression molding

- Stamping, punching and forging

- Grinding

- Welding

- Furnace tending

Key Steps for Successful CNC Machine Tending Integration

Setting up an automated CNC tending cell, which includes an industrial robot or cobot, mounting, the CNC machine, part feeding systems and a controller, is complex. Successful integration requires careful planning.

Step 1: Select the right robot: Consider payload, reach and whether a collaborative or industrial robot is the best fit.

Step 2: Choose the mounting configuration: Decide whether a stand, cart or ceiling mount will be most suitable for the workspace and will maximize the robot’s effectiveness.

Step 3: Define the workflow: Map out every task the robot must perform, from picking the part to placing it in the vice to removing the finished product.

Step 4: Integrate with CNC operations: For maximum efficiency, carefully plan how the robot will interact with the machine, including operating vices and opening and closing doors.

Step 5: Establish communication: Determine the best way for the robot and machine to communicate, whether through simple push buttons or more complex direct integration with the control system.

Step 6: Prioritize Safety and Conduct a Risk Assessment: Perform a thorough risk assessment to identify potential hazards associated with the robot, part handling, and CNC operations. Implement appropriate safeguarding measures such as light curtains, interlocks, or area scanners to protect operators. This step ensures compliance with safety standards and helps prevent costly accidents or downtime once the system is running

Work Smarter with JHFOSTER Robotic Machine Tending Solutions

Robotic machine tending is the key to unlocking greater productivity, efficiency and safety in your operations. As your experienced automation partner, JHFOSTER is ready to guide you through every stage of your machine tending project from initial evaluation to final integration to support. Request a quote today.