Top 5 Motion Control Trends Shaping Automation in 2025 and Beyond

As industries pursue higher efficiency, precision, and adaptability, motion control is no longer just a supporting technology, it’s a driving force in next-gen automation. At JHFOSTER, we help manufacturers stay ahead by providing motion solutions from industry leaders like IMI.

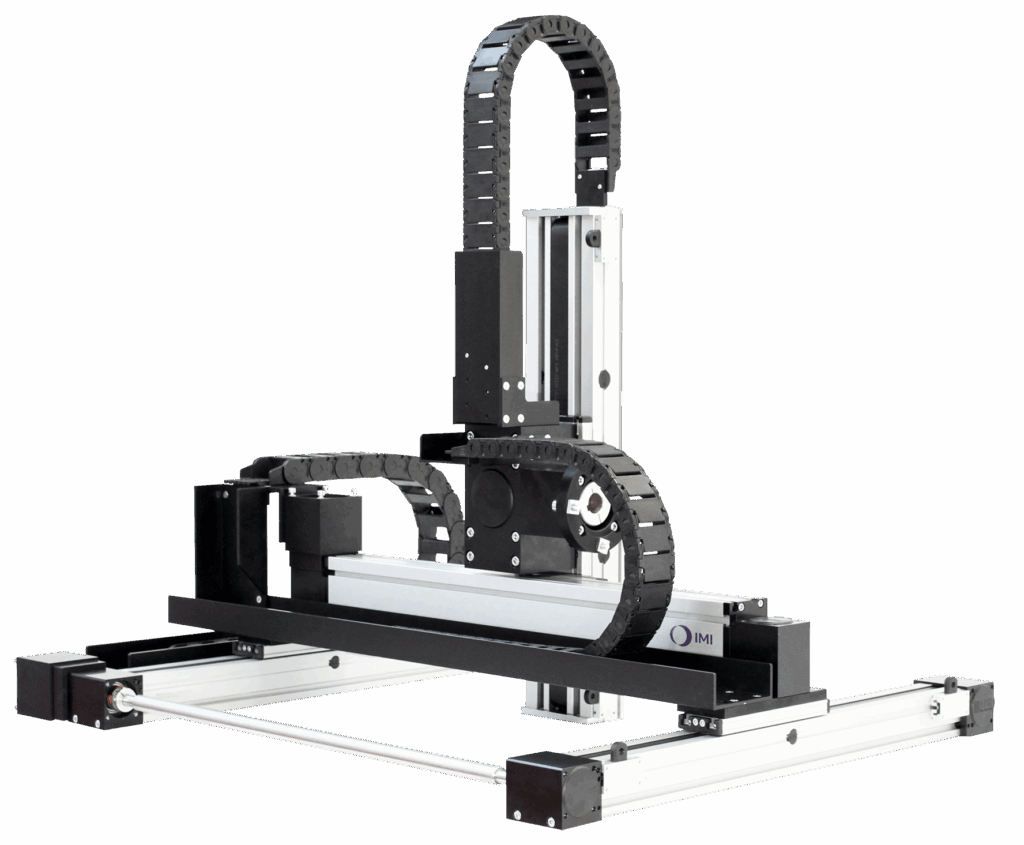

From intelligent actuators to compact, energy-efficient systems, today’s motion technology is smarter, smaller, and more connected. Here are the top five motion control trends redefining the future of automation and how IMI’s innovations, available through JHFOSTER, can help future-proof your operations.

1. What is intelligent motion control, and how is it changing automation?

Smart motion systems go beyond movement – they gather data, adapt, and optimize performance in real time. More manufacturers are turning to these intelligent components to reduce downtime and improve control.

IMI’s intelligent motion control solutions include:

- Smart actuators with integrated feedback

- Electronic proportional valves

- IIoT-ready devices with real-time diagnostics

These systems enable predictive maintenance, tighter control of motion profiles, and seamless integration with modern automation platforms.

Pro Insight: Predictive capabilities can prevent up to 30% of unplanned downtime

Explore IMI’s Motion Control Solutions

2. How does miniaturization improve motion control systems?

As automation extends into compact, high-density environments, motion components must deliver full functionality in smaller footprints. This is especially critical in fields like medical devices, lab automation, and electronics assembly.

IMI’s compact product lines feature:

- Space-saving valves and manifolds

- Low-profile pneumatic cylinders

- Miniaturized actuator technologies

These solutions maximize performance without increasing machine size—making them ideal for OEMs and system designers looking to do more with less.

Talk to JHFOSTER Engineers About Miniature Systems

3. How can motion control systems help reduce energy use and support sustainability?

With rising energy costs and growing environmental targets, efficient motion systems are no longer optional—they’re essential. Motion control plays a key role in reducing compressed air waste and lowering operational carbon footprints.

IMI’s sustainability-focused offerings include:

- Low-leakage valve designs

- Lightweight actuator assemblies

- Optimized FRLs and air prep units

JHFOSTER partners with customers to audit current systems and implement solutions that improve both energy performance and equipment lifespan.

Sustainability Tip: Even a 10% reduction in air leakage can result in thousands in annual energy savings.

Get a Custom Energy Efficiency Review

4. Can motion control components be customized for unique applications?

Yes. No two production lines are the same, and modularity is key to meeting exact performance requirements without long lead times or high engineering costs.

Customizable features in IMI’s product lineup include:

- Adjustable stroke lengths and force ranges

- Specialized porting and mounting configurations

- Material options for food-grade or harsh environments

Whether you’re dealing with unique force needs or challenging installation spaces, JHFOSTER can help configure a motion system that fits.

Request a Custom Configuration Today

5. How do motion control components integrate with modern automation systems?

In today’s facilities, motion systems must work in sync with PLCs, sensors, drives, and other technologies. Seamless integration from the start avoids communication issues and delays during installation.

IMI components are engineered for:

- Plug-and-play connectivity with PLCs and fieldbus protocols

- Pneumatic-electronic hybrid system compatibility

- Easy integration into multi-technology automation platforms

JHFOSTER provides hands-on support to ensure clean, cohesive system integration that works right out of the gate.

Tip: Plan motion system integration early to avoid mismatches between pneumatic and digital infrastructure.

Connect With Our Automation Integration Team

Power Your Future with IMI + JHFOSTER

Whether you’re launching a new production line or upgrading aging systems, JHFOSTER helps you deploy future-ready motion control solutions that align with your business goals.

We don’t just sell parts, we partner with you to solve complex challenges, improve operational efficiency, and prepare your systems for the demands of tomorrow.

Want to modernize your motion systems?

Let’s start a conversation.

Contact Us | Request a Motion Control Assessment

Frequently Asked Questions (FAQ) About Motion Control Trends for 2025

| 1. What are the key trends in motion control for 2025? |

| The top motion control trends for 2025 include intelligent motion systems, miniaturized components, energy-efficient designs, customizable solutions, and seamless system integration. These trends are driven by the need for smarter, faster, and more sustainable automation. |

| 2. How do smart motion control systems reduce downtime? |

| Smart actuators and valves offer real-time diagnostics and feedback, allowing for predictive maintenance. This means issues can be addressed before failure occurs, significantly reducing unplanned downtime and maintenance costs. |

| 3. Why is miniaturization important in motion control? |

| Miniaturized motion components save space and allow automation in compact environments, such as medical devices, electronics assembly, and lab automation. These components offer high performance without increasing system size. |

| 4. What makes a motion control system energy-efficient? |

| Energy-efficient systems use technologies like low-leakage valves, lightweight actuators, and optimized air prep units. These designs help reduce compressed air usage, cut operating costs, and contribute to sustainability goals. |

| 5. Can I customize motion control components for my application? |

| Yes. Many motion control products, like actuators and valves, offer modular options that can be configured for specific stroke lengths, mounting styles, force outputs, or material compatibility—without long lead times. |

| 6. How do motion components integrate with PLCs and control systems? |

| Modern motion control devices are designed to be plug-and-play with PLCs, fieldbus networks, and hybrid systems. Choosing components that support your control architecture ensures reliable, scalable integration. |

| 7. What industries benefit most from these motion control innovations? |

| Industries such as medical device manufacturing, life sciences, electronics, food and beverage, and general industrial automation benefit from intelligent, compact, and energy-efficient motion technologies. |

| 8. Where can I get help designing or upgrading my motion control system? |

| JHFOSTER offers expert engineering support, product selection guidance, and integration assistance. Our team can help you design, configure, and implement motion control solutions tailored to your needs. |