The Different Types of Actuation

From start to finish, the manufacturing process is always in motion, and most of that motion is powered by one of the three common types of actuation: pneumatic, electric, or hydraulic actuators. What differentiates these power sources, and why should you use one over another?

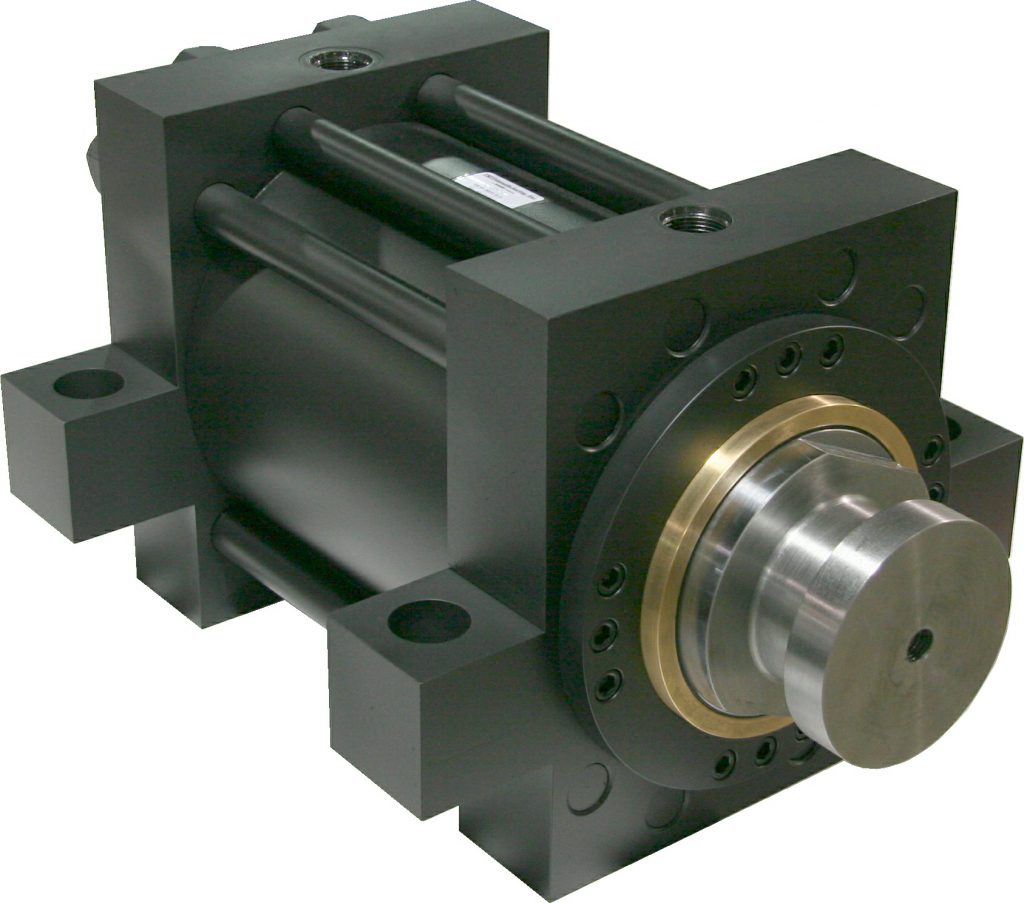

Hydraulic

One type of actuation is hydraulic. Hydraulic actuators utilize hydraulic fluid, usually a specially designed oil, to generate mechanical motion. Liquids are virtually impossible to completely compress, meaning that hydraulic actuators can produce a huge amount of force relative to their size.

On the flipside, hydraulic fluids are messy and require routine cleaning to keep machines safe and operational. Due to the weight of most liquids, hydraulic actuators are much heavier than relative pneumatic and electric actuators.

Hydraulics are commonly used in heavy duty applications such as construction and mining equipment.

Pneumatic

Pneumatic actuators employ compressed air to create motion. Compressed air is relatively cheap and easy to generate; many machines already utilize compressed air in some way, meaning pneumatic actuation is a no-brainer for some systems. Pneumatic actuators can produce a substantial amount of force with only small changes to air pressure. Small comparative footprints and a wide array of models make pneumatic actuators very attractive to many machine builders.

Compressed air as a power source can be noisy. It also requires systems of tubing, reservoirs, filters, valves, and other air treatment elements to ensure the actuators continue functioning at full capacity. Depending on the size of the application, these systems can become quite complex if not well engineered or maintained.

Pneumatics can be found in nearly every application and industry out there.

Electric

Electric actuation is a much newer technology compared to hydraulic and pneumatic options. It provides clean, quiet motion with incredible accuracy and repeatability. They require very little maintenance thanks to their reliance on electrical power over messier fluids. Many models integrate well with up-and-coming robotics and Industry 4.0 technologies.

Electric hook-ups are less common to find in pre-existing machines, so some engineers will find it difficult to integrate electric actuators into system designs. Due in part to their high-tech designs, electric actuators are also more expensive than similar hydraulic and pneumatic counterparts.

Electrics are ideal for applications that require precise movement and high tech integrations, such as pick and place, 2-axis/3-axis motion profiles, and more.

Contact Us

Still not sure which power source is the right solution for your application needs? Contact us today to receive information and guidance from our team of experts.