The Biggest Trends in Manufacturing Automation for 2023

In recent years, industries worldwide have seen the benefits of including automation in their manufacturing process. The demand for manufacturing automation will continue to rise.

The benefits include reduced expenses, better product quality and increases in productivity. One of the most notable manufacturing automation trends involves making technologies easier to program and deploy. Automated machinery is becoming more widely used and more advanced. As technology becomes more readily available, best practices for new systems are being honed. Showing returns on investment from manufacturing automation is getting easier. As 2023 continues, more companies are going to want to leverage the best in automation.

Advanced Safety Equipment

Employee safety will continue to be a priority. Advanced safety technology will be more widely available. Smart helmets are among the safety equipment that will be more readily available. These helmets have sensors to monitor the vital signs of workers. They have GPS trackers to help locate workers in case of an emergency. Smart helmets use sensors and artificial intelligence cameras to record information about the user’s surroundings. This includes thermal data and valve readings. These helmets can show stored information to the wearer including worker instructions and safety guidelines. An exoskeleton is another example of advanced safety equipment. It is a protective body covering designed to assist workers with lifting and other physically demanding tasks. Exoskeletons can amplify, reinforce, or augment the performance of a worker’s body.

Skilled Worker Shortages

So far in 2023, there have not been enough skilled workers to meet with demand. There will be a shortage of professional developers in the artificial intelligence area. There will be a dearth of project managers and trained analysts for automation projects. Manufacturers will be partnering with automation companies for support. Industry analysts say skills shortages will persist in 2023. Companies will be handling challenges such as having the right talent in place within their facilities. Some manufacturing automation trends center on increasing productivity. Typically, manufacturers will need to get more done with fewer workers. Due to the current shortage of workers, prospective manufacturing employees have some leverage. They are using this leverage to encourage manufacturers to provide improved work environments. Among the workplace conditions they want are wellness programs, flexible hours, higher wages, and advancement opportunities.

Increased Use of Robot Workers

Industrial trend analysts believe 2023 will be a year driven by turnkey robotics solutions. Manufacturing leaders are becoming more open to using automation.They are seeing that it is easier than in past years to take advantage of automation in the manufacturing industry. Labor and skill shortages will likely force more manufacturers to invest in robots. Robotic work can add to the accuracy and precision of the workflow process. Typically, they increase product quality and consistency while improving workflow process efficiency, especially when performing repetitive tasks.

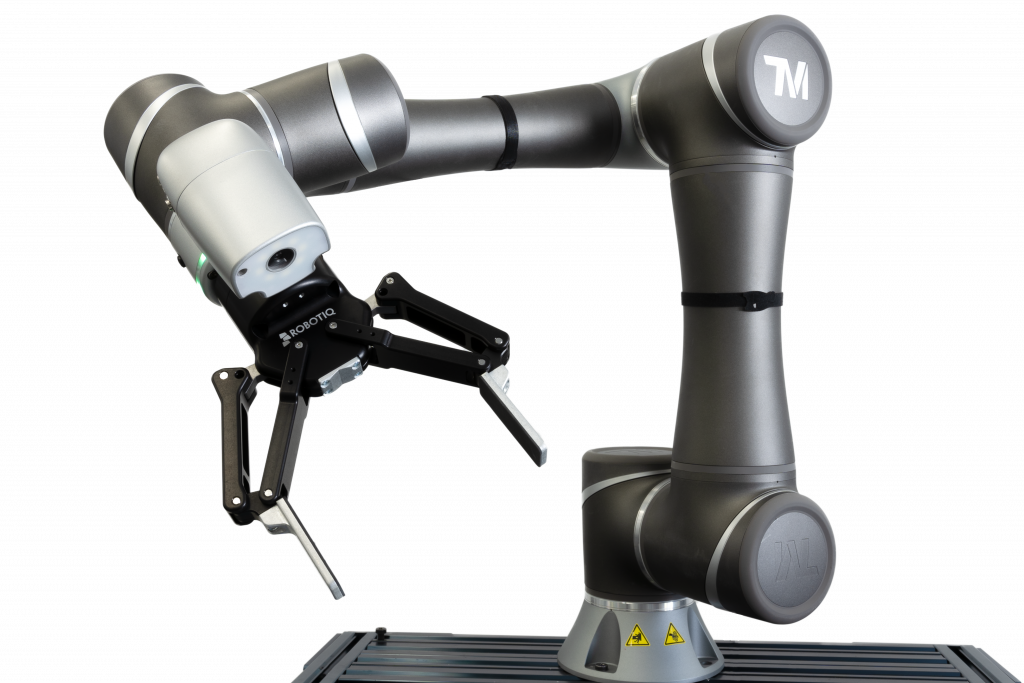

Increased Use of Cobots (Collaborative Robots)

Due to ease of programming and ability to work alongside employees in many applications when using their unique safety features, collaborative robots can help increase productivity and make factories more versatile. They can be used in almost unlimited applications ranging from assembly, sorting, pick & place, grinding and polishing, quality control and inspection to name a few. Cobots can allow a single worker to do more with less and reduce the number of workers needed to perform the same specific operation resulting in increased production, efficiency and improved quality

The use of Warehouse Drones is Increasing

Drones are rising in popularity in manufacturing, among other industries. They provide companies with the ability to work more efficiently. Drones can transport equipment and supplies from one place to another so there is less stress and potential injury to manual laborers. They can be used for production by delivering small pieces and parts from one line to another. They are useful in hazardous environments. They eliminate the need for workers to be exposed to safety hazards. Uses for drones include managing inventory, collecting data, and delivering products. They can hover over warehouse inventories, scanning items to monitor how many are in stock.

Who can I contact about the needs of my business?

At JHFOSTER we are committed to learning about your business and helping you to resolve your manufacturing issues. JHFOSTER can provide you with products that suit your needs. Our expertise is in working with our clients to help them achieve optimal efficiency in their facilities. One of our technicians can provide you with the information that it takes for you to do your job effectively and efficiently. We are a leading distributor of automated systems and robotics. A JHFOSTER representative is available at 855.688.0043.