Reasons to Upgrade Factory Equipment to Industry 4.0 Tech

You’ve likely heard the term “Industry 4.0” being tossed around in manufacturing circles. Maybe you’ve looked into bringing such technologies into your factory operations and are actively doing so as you read this post. Or maybe you’re taking more of a “wait and see” approach to observe how this whole concept shakes out. If you’re among the latter group, we’d urge you to reconsider — or else you could risk falling far behind your competition sooner rather than later.

You see, Industry 4.0 isn’t something that’s on the horizon or that will become a significant focus down the line in the years to come. It’s something that’s already here and being implemented and utilized by the firms that are serious about increasing their market share and delivering a better overall product or service. If you’re not up on all of the benefits that Industry 4.0 stands to offer, we’d urge you to start researching the technology and making plans to integrate such into your shop floor equipment as you’re able. Yes, there’s always a cost associated with any type of equipment upgrade, but as you’ll see from reading this post, the upfront cost is able to be more than offset by the long-term gains of implementing such technology. Yes, the return on investment has the potential to be significant. Read on for more information about why it just makes sense to upgrade your factory equipment to Industry 4.0.

Industry 4.0 Explained

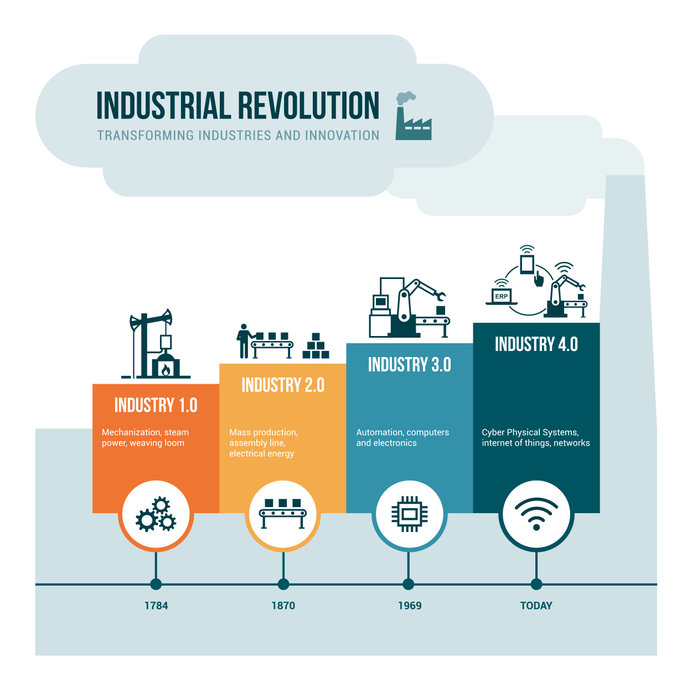

Let’s begin this post by first discussing just what Industry 4.0 is so you have an idea of why it’s beneficial to upgrade factory equipment to such standards. Industry 4.0 essentially refers to the ongoing fourth industrial revolution. However, unlike previous industrial revolutions, this one is being driven by advances in smart technology and connectivity. In other words, this fourth revolution is being driven by the likes of artificial intelligence, robotics, automation, the Internet of Things (IoT) and enhanced connectivity. In a manufacturing environment, it’s characterized by all equipment and machinery essentially “talking” with each other to realize never before seen efficiency improvements as well as significant energy savings.

While many have already implemented Industry 4.0 practices into their environments, it’s worth noting that this fourth revolution is still largely a work in progress. That is, it is evolving and will continue to evolve as technology does.

Why Upgrade Factory Equipment to Industry 4.0?

Work Smarter, Not Harder

The concept of working smarter, not harder isn’t a new one in business. But despite it being a catchy phrase, few truly live it. That’s one of the big benefits of adopting Industry 4.0 technologies in your manufacturing environment. By doing so, all of your equipment can become interconnected, delivering a wealth of data that you can analyze and learn from to see how processes can be further optimized. When you upgrade your equipment to work this way, it truly enables you to work smarter and not necessarily harder. The end results are an increase in productivity and efficiency, as well as the ability to quickly diagnose any issues so that they can be resolved in a prompt manner. Industry 4.0 technologies allow you to see things in real-time, also delivering a greater degree of transparency for everyone throughout your organization.

Reduced Costs

When productivity is enhanced and processes are optimized, certainly a higher-quality end product is often the most significant byproduct. But another significant byproduct is reduced operational costs. Whether it’s through error avoidance, energy savings or eliminating waste from your manufacturing process, any cost savings realized via Industry 4.0 can be passed down to the customer or go to boost a firm’s overall bottom line. Either way, it’s a win for all parties involved.

Company Growth

Every company wants to continue to grow and expand, but the importance of doing so sustainably cannot be underestimated. That’s another big benefit of Industry 4.0 — it can create new competitive advantages for any manufacturing organization and help usher in this sustainable growth. Because you’re optimizing efficiency and working smarter, you’re bound to increase productivity, quality and get your product offerings to the market faster. As a result, you’ll continue to establish your firm as an industry leader.

Contact JHFOSTER Today

Industry 4.0 manufacturing is still largely in its evolution, but it’s here — and it’s significant for the factories that implement the technologies correctly. In a business environment where change is inevitable and the sustainability of said companies often hinges on how well they’re able to change and adapt, Industry 4.0 is something that firms should definitely consider investing in before it’s too late. The long-term benefits far outweigh any upfront costs of integrating said technology into your facility, and the competitive advantages that you’re bound to develop over your competition cannot be understated either. For more information on Industry 4.0 technologies and the potential they can have on your factory floor, contact JHFOSTER today.