How Proportional Solenoid Valves Are Used in Manufacturing

Proportional Solenoid Valves are often leveraged in manufacturing processes. They are utilized for applications where flow or output pressure requires variations, remote control and precision. Proportional Solenoid Valves are widely used in medical device manufacturing and semiconductor production. They are also utilized in life sciences product manufacturing, among other industries.

Proportional Solenoid Valves are ideal for use in the production process because of their:

- Dependability

- Cost-effectiveness

- Fast response times

- Accuracy in control of flow or pressure

- Flexibility

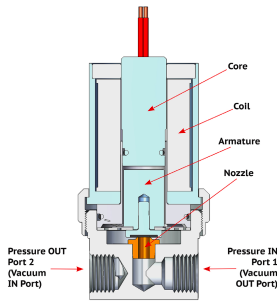

How Does a Proportional Solenoid Valve Work?

A Proportional Solenoid Valve controls fluid flow rate or pressure. It does this by adjusting the opening size within the valve. Controlled remotely, the plunger/spool opens or closes a valve position. It can be partially open – not just open or closed, hence the term “proportional.”

The regulated flow rate adjusts parameters affecting a process in a system. These parameters include pressure or flow. In an automatic control valve, the restrictor (in this valve the restrictor is a plunger/spool) is controlled by a signal from an actuator.

A solenoid is an electric coil with a moveable plunger/spool at the center. A Proportional Control Valve uses a direct solenoid or solenoid pilot as an actuator/controller for variable valve positioning. Direct solenoid control is recommended for dynamic applications.

Solenoid pilot control is a lower cost alternative for static applications. Closed loop control with feedback is also available if precise output is required in dynamic applications.

Are Proportional Solenoid Valves Adaptive?

Proportional valves are flexible. Engineers will have the capability to choose the flow rates that they need. They just need to make sure the rates are within the valve’s range. Manufacturers can provide custom variations on valve design to suit the requirements of a particular system.

What Does the Inside of a Proportional Solenoid Valve Look Like?

Proportional Solenoid Valves are components in manufacturing processes. They offer precision control of fluid/ flow rates or pressure.

This type of valve is known for their:

- Dependability

- Cost-effectiveness

- Response times

- Accuracy in control of flow or pressure

- Flexibility

How Are Proportional Solenoid Valves Used in the Production Process?

The precision of Proportional Solenoid Valves and their variable output capacity makes them indispensable for production applications. They are an integral part of manufacturing processes. These valves are utilized for applications where flow or output pressure requires variations, remote control and precision.

The capabilities of this type of valve make them a suitable option for medical device applications that require precise fluid/pneumatic flow or pressure control.

The medical device manufacturing industry uses Proportional Solenoid Valves in anesthesia and ventilator gas mixing. These valves are in ventilator patient delivery for controlled breathing. For medical components and packaging, they are ideal for leak detection.

Semiconductor manufacturers utilize Proportional Solenoid Valves for precise gas control. The life sciences field uses them in the production of pharmaceuticals. They are used in the manufacturing of biotechnology-based foods and medicines. In the consumables area this type of valve is utilized in food processing and the production of nutraceuticals.

Other uses for Proportional Solenoid Valves include:

- Leak detection

- Valves and coolant

- Braking systems

- Irrigation

- Web tensioning

- Counterbalancing

- Spraying

What Are Safety Features of Proportional Solenoid Valves?

This valve type is known for its safety features. This valve features parameter control as it can be set up on a computer. It has signal control, meaning that the valve will close if it receives an input signal less than the predetermined value. The flow of gas, fluids and air features remote control, which is another plus for safe use.

How Long Do Proportional Valves Last?

The life of a valve is dependent upon its design and level of maintenance. Typically, they do not show wear because of inherent low friction. This type of valve has low mass armatures which have no contact points.

What Are Primary Benefits of Proportional Solenoid Valves?

This type of valve can be advantageous where variable flow rates are needed. They give the user exceptional control of fluid/pneumatic flow rates or pressure. Proportional Solenoid Valves provide an elevated level of precision control for manufacturing applications.

Who can I contact if I have questions?

JHFOSTER is committed to providing solutions that increase efficiencies and exceed production demands. We reduce manufacturing costs while raising your firm’s level of success.

Contact an expert at JHFOSTER today. One of our team members would be happy to assist you in choosing the right valve for your application.