How Does a Rotary Screw Air Compressor Work?

Rotary screw air compressors deliver a modern, durable solution for high-demand industrial applications. The reliable, continuous-duty air system afforded by rotary screw compressors allows you to start working faster, smarter and more efficiently. The compressed air experts at JHFOSTER can help with the selection, installation and maintenance of your rotary screw air compressor.

How Rotary Screw Air Compressors Work

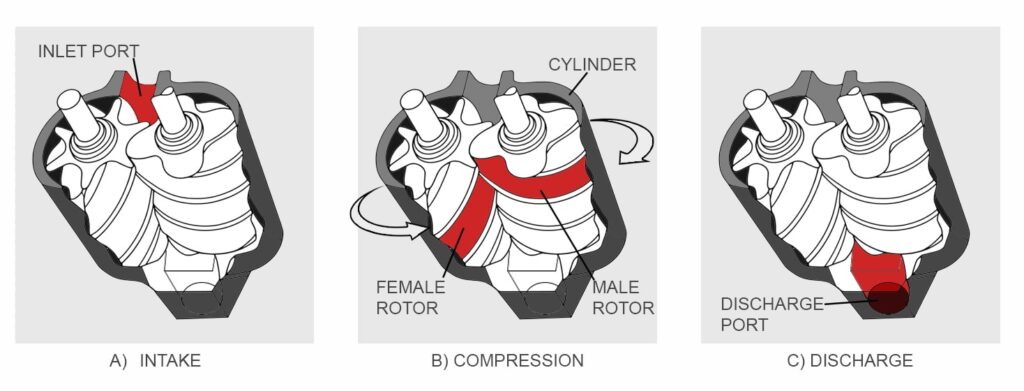

The rotary screw air compressor working principle is key to durability in heavy-duty industrial applications. In rotary screw compressors, air compression is achieved by two intermeshing, helical rotors (one male and one female) that continuously spin.

Basic operation:

- Intake: Air is drawn into the compression chamber and trapped between the rotating rotors.

- Compression: As the rotors turn, the space containing the air constantly decreases in volume, compressing the air.

- Discharge: The highly compressed air is pushed out of the airend housing.

Understanding Rotary Screw Compressor System Components

There are four integral compressor parts that enable performance and longevity of the unit.

1. Air End: As the heart of the system, the air end contains the rotors where compression takes place.

2. Drive Motor: The drive motor powers the rotors. Variable speed drive (VSD) technology continuously adjusts the motor’s speed to match the system’s air demand, maximizing efficiency.

3. Air/Oil Separator: In oil-flooded models, this component is crucial for removing lubricant from the compressed air before it enters downstream equipment.

4. Cooling System: The cooling system manages the heat that is generated during the compression process, ensuring reliability and preventing system damage.

The Advantages of a Rotary Screw Compressor

In addition to reliability, rotary screw compressors offer significant advantages, including:

True continuous duty: Unlike most piston models, rotary screw compressors are designed for continuous duty (24/7 operation). They require no cooling-off period so they support operations that have continuous air demand.

High efficiency: Rotary screw compressors equipped with VSD motors can dynamically adjust to your air needs, providing significant energy savings when compared to many fixed-speed models, reducing operational costs.

Exceptional reliability and life expectancy: With modern technology, superior design and a simple operating principle, rotary screw compressors provide consistent, reliable performance and a life expectancy of 10 to 20 (or more) years if properly maintained.

Quiet operation: The design and operation of modern rotary screw compressors make them a quieter option compared to other technologies. The lower noise levels improve the work environment and enhance worker safety.

While rotary screw compressors do have a higher initial investment than other compressor types, their reliability and efficiency often reduce long-term operational costs. Additionally, because they are so efficient when equipped with VSD, utility rebates may be available in your area, potentially offsetting some of the upfront equipment cost.

JHFOSTER: Your Compressed Air Expert

Choosing the right rotary screw compressor and maintaining it correctly are vital to your productivity. As your partner through the entire lifecycle of your unit, JHFOSTER can provide expertise from initial sizing to ongoing maintenance of your rotary screw air compressor.

Contact us today to schedule a compressed air audit to evaluate your current system needs and to find the most effective solution for your application so you can start operating smarter and more efficiently.