Choose the Right Vacuum Pump for Your Compressed Air System

We say this pretty often about choosing equipment. The saying holds true, though. Choosing the right Vacuum Pump for your Compressed Air System really depends on the application you are using it for. There are five main types of vacuum pumps. Each is suited best for a specific purpose.

So let’s break down what a vacuum pump is and what it does generally. Then, we’ll go over each pump type and when it is best used.

What is a Vacuum Pump Exactly?

A vacuum pump is an industrial device that removes gases from enclosed spaces. The purpose of this is to create a vacuum. Hence why the equipment is called a vacuum pump.

Many times people refer to a compressor and a pump as the same thing. As you well know, this isn’t really true. A pump moves liquid or gas from one place to another. A compressor, on the other hand, creates a smaller volume out of gas, then moves it somewhere else.

Types of Vacuum Pumps

Rotary Vane

Rotary Vane Pumps work by positive displacement. The pump forces a fixed amount of gas from the inlet pressure section to its discharge. These pumps have a series of vanes that are mounted to a rotor that turns within a cavity. With each vane rotation, centrifugal force extends the vanes from their slots creating compression cells.

How They Are Used

While Rotary Vane Vacuum Pumps can be used for many different applications, it is most commonly used in the transportation industry to power systems like automatic transmissions and power steering. They are also commonly used in the beverage industry for powering soft-drink dispensers and espresso machines.

Rotary Screw – Oil Flooded

These pumps are made of two parallel rotary screws that are synchronized to turn in opposite directions. The result is compression action. Compression occurs in the direction of the pump’s discharge port. Pump cooling occurs through an oil lubrication circuit that has an air-cooled heat exchanger.

How They Are Used

These vacuums are used most often in centralized systems rather than in point of use/application-specific situations. Oil-free versions are also available.

Claw

Claw vacuum pumps have two rotors that continually rotate. These rotors never come into contact with each other. The rotation moves gas along from the suction side to the pressure side creating pressure. This pressure is what ultimately compresses the gas. Cool air is brought into the compression housing to reduce the temperature before it leaves the pump.

How They Are Used

Claw Vacuum Pumps are highly versatile. They are used in many different industry applications including pick-and-place machines, plastic manufacturing, paper manufacturing, and even scientific applications. However, by far the most common use is in medical applications. These pumps are oil-free meaning the medical field doesn’t have to worry about contamination when using these pumps.

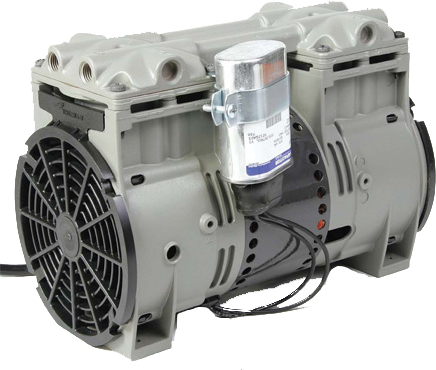

Articulated Piston

Think of an articulated piston vacuum pump like your car’s engine. While the piston moves down inside the cylinder, air is drawn into the intake valve. When the piston moves upward, this air escapes through the exhaust valve. The piston rings are then used to seal the piston to the cylinder.

How They Are Used

Articulated Piston Vacuum Pumps are tough little machines. These pumps are best used for applications that require a long-use life and high flow rates. This means they are well suited for industrial applications needing a hardy machine to power systems.

Liquid Ring

Liquid ring pumps operate similarly to rotary vane pumps in that they operate with positive displacement. The liquid ring’s pump rotates inside the pump casing. The impeller and blades are then sealed by the liquid ring. Liquid is then sucked into the compression chamber to create stability for the ring. Gas is compressed during each impeller rotation.

How They Are Used

Liquid Ring Vacuum Pumps are best for tough conditions that may require a high capacity for contaminants. These pumps also require low maintenance. The industries that these pumps support include biodiesel plants, printing companies, food and beverage applications, and plastic manufacturing.

Contact Us

If you have more questions on which vacuum pump you should be using, please contact us by email or phone. We’d be happy to help you with your selection!