Category: Uncategorized

Modular Automation is the Future of Custom Manufacturing

Traditional industrial automation offers centralized control of production lines to provide increased efficiency and other benefits for manufacturers with static production runs and demand. However, for custom manufacturing businesses or those with fluctuating demand and/or smaller runs of a variety of products, reconfiguring and reprogramming traditional automation systems for production changes can be complex, costly […]

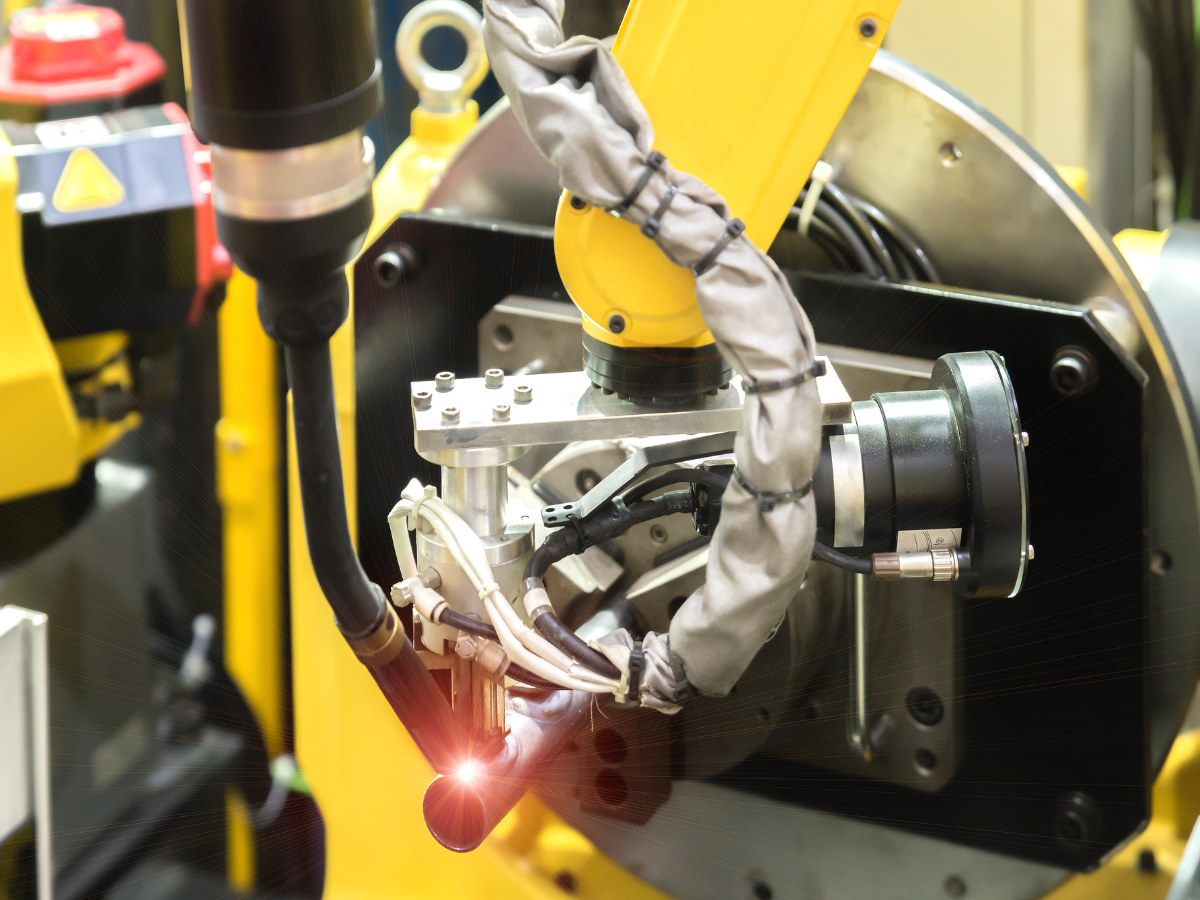

Advanced Robotics in Manufacturing: The Next-Gen Automation Solution

Traditional industrial automation and robotics have successfully been used to increase efficiency, productivity, safety and product quality for some time now. But, more recently, the addition of advanced technologies such as integrated vision systems, artificial intelligence (AI) and intuitive programming software are taking robots and cobots in manufacturing applications to the next level. This blog […]

IP67-Rated Balanced Solenoid Valves are Built for Harsh Conditions

Harsh manufacturing environments, such as those found in the food and beverage sector, call for the use of durable, waterproof, and dust-proof solenoid valves in flow control applications. IP67-rated valves can sometimes meet the criteria and can help extend the life of equipment used in challenging conditions. This blog will explore pressure balanced solenoid valves, […]

Optimizing Pneumatic System Design for the Best Performance

In pneumatic systems, pressurized air generates motion that is used to drive automated equipment, manufacturing processes and air-powered tools and devices in a reliable and cost-effective way. But to achieve top-notch performance in any application, properly designed air systems are a must. This blog will explore and explain pneumatic systems and how careful selection of […]

SCARA Robot vs. 6-Axis Robot: Which is Best For Your Application?

While industrial robots can lend speed, accuracy and greater levels of efficiency to an operation, they are not a one-size-fits-all solution. As a matter of fact, selecting the right robot for an application is critical to the success of any automation project. In this blog, we’ll compare and contrast two of the most commonly applied […]

Improve Efficiency with a Variable Speed Compressor

As manufacturers grapple with maximizing productivity while also cutting costs, increasing energy efficiency to reduce the electric bill is a growing trend. For industrial applications that have a fluctuating demand for compressed air, upgrading to a variable speed air compressor may be an effective way to improve air compressor efficiency and reduce the facility’s power […]

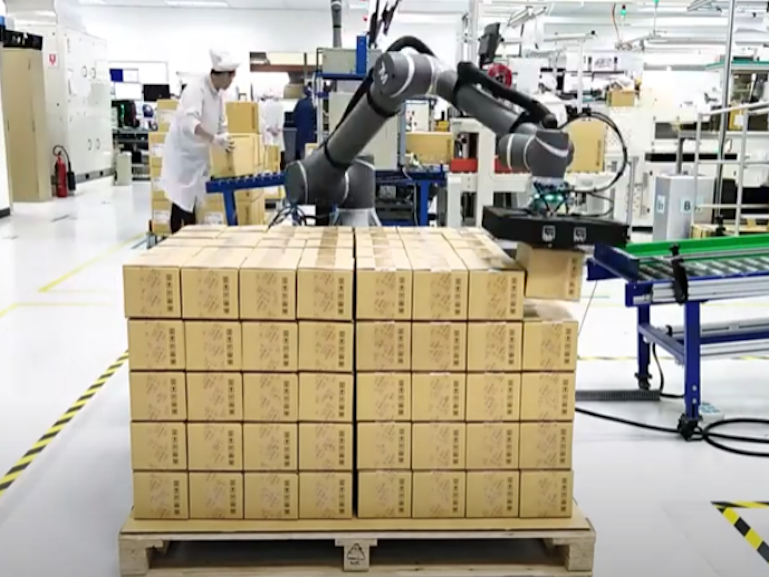

Automation Supports Cleanroom Environments

Maintaining a contamination-free cleanroom environment is crucial for electronic manufacturers and in life sciences manufacturing, among other industries, as it assures that sensitive products are produced under the purest conditions. The use of automation and robotics in these environments ensures that the cleanroom provides the necessary sanitary surroundings, while also enhancing process efficiency and product […]

The Role Actuators Play in Keeping Robots in Motion

Robotic actuators are an important component in any industrial robotic system as they convert energy into smooth and accurate robotic performance, essentially serving as the muscle behind a robot’s movements. The blog will explore the various types of actuators in robotics, the importance of robotic actuators in industrial applications, the benefits of using robot actuators […]

TM30S: Breaking Barriers in Collaborative Robots

As the use of cobots in manufacturing continues to grow, advances in robotics are giving rise to new technologies, such as Techman Robot’s TM30S, an new collaborative robot that excels in high-volume industrial tasks. This blog will explore the advantages of using robotics in manufacturing and discuss the features of the TM30S so you can […]

Is an Oil-Sealed or Dry Rotary Vane Pump Right for My Application?

Rotary vane vacuum pumps, offer reliable solutions for a broad range of food, packaging, chemical, pharmaceutical and other industrial applications. Further, because they are available as oil-lubricated and dry rotary vane pumps, these robust vacuum pump options may serve in both general and sensitive pump applications. This blog will explore the differences between oil-sealed and […]