Advances in Robotics Allow More Food Processing Applications

While robotic automation has been used in the food manufacturing industry for years, most applications have been in food packing and palletizing, rack unloading and secondary pick-and-place operations. Recent technological advances have led to the expansion of robotic equipment into many unexpected food processing and food preparation applications.

Advances in Automation for the Food Industry

Previously, robotic automation was used primarily in packing, palletizing and pick-and-place functions in the food industry for a variety of reasons. First, end of arm tooling was not gentle enough to handle delicate food items. Second, robots were not suitable for use in operations that required food-safe equipment. Third, robotic automation was not designed to withstand the harsh cleaning regimes employed in food processing facilities.

However, that has changed as more manufacturers of robotic automation are now providing food-safe robots with specialized end of arm tooling. Today, specialized robots are constructed using hygienic designs that eliminate potential crevices where bacteria or other contaminants might accumulate and they are often fabricated of stainless steel and materials that can withstand the daily caustic, high-temperature cleanings used in the food industry. Further, to avoid the risk of contamination related to accidental lubricant leakage, food-grade lubricating oils are employed. The U.S. Food and Drug Administration (FDA) has recently approved several robots and gripper technologies for use in food handling applications.

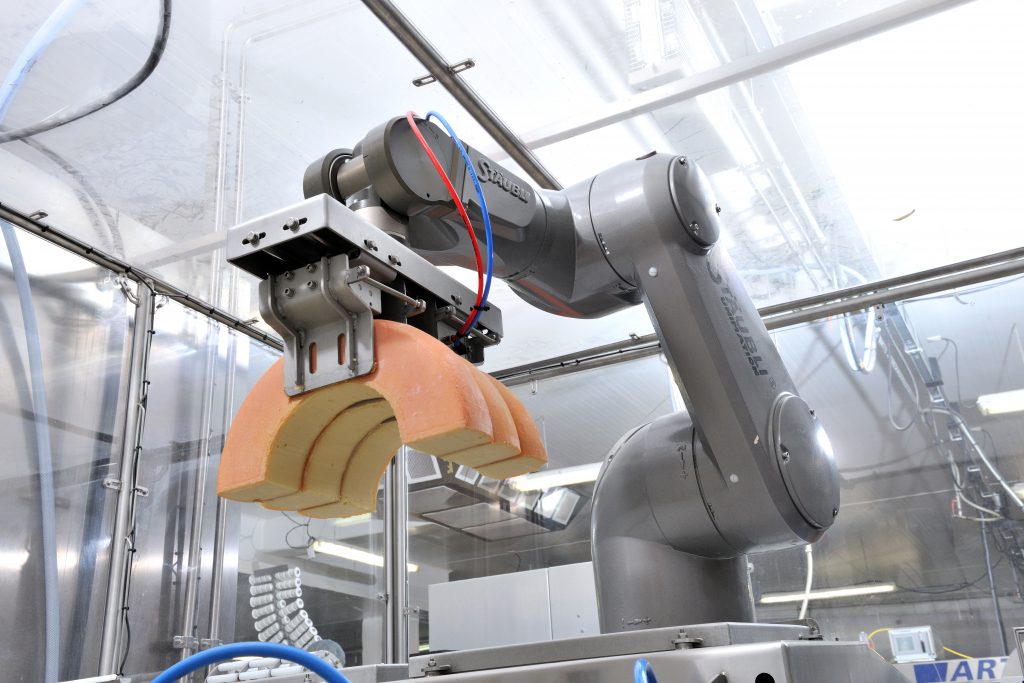

The introduction of more advanced grippers has also promoted the use of robots in applications where it was not previously possible. Today there are grippers that can handle soft, sensitive food items, such as produce and cheeses, without damaging them. Other end of arm tooling, such as vacuum grippers, suction cups and manipulation devices specially designed for the various shapes and rigidity of food items, allow more prevalent use of robots in food processing and handling applications. There are specialized “gloves” available for grippers that enable sensitive end effectors to withstand daily sanitation, as well.

Often the inclusion of machine vision along with these advanced grippers allow robots to identify, handle, pick up and/or properly orient foods of different shapes and sizes. In the past, this was a problem in the food industry because many food items are not of a standard size or shape.

Novel Food Industry Applications

Previously relegated to food applications that didn’t require much “intelligence,” sanitation or dexterity due to the shortcomings addressed above, food-grade robots are now being employed in some extraordinary and surprising food preparation applications, including:

| Meat processing/butchering | Deboning, cutting, slicing and even creating pre-made skewers are just some of the ways robots are used in meat processing. Even delicate seafood can now be deboned by robots. In addition to providing efficiency, robotic automation also increases facility safety in meat processing applications as many occur in freezers or meat lockers where it can be hazardous for employees to remain for long periods, while also eliminating knife injuries for human workers. In addition, many robots debone meat by dismantling carcasses rather than cutting meat off the bone, which prevents knife damage to improve product quality. |

| Cutting and slicing processes | Thanks to machine vision and specialized end of arm tooling, robots can now be relied upon to cut and slice delicate vegetables and other produce into standard size pieces prior to processing, canning or freezing. Robots can also be used to cut and slice delicate fish filets into uniform sizes. |

| Dairy | In addition to robots made for milking cows and collecting eggs, robots can now be employed to handle delicate items like cheese. Robots have been combined with various automated systems to accomplish tasks such as de-rinding wheels of cheese and cutting and slicing cheeses. |

| Pick and place in new applications | Once again, the development of specialized end effectors has allowed robots to handle fruits, cheeses and other delicate items for sorting or in preparation for further processing. The addition of machine vision systems with these new end of arm tooling options also allows robots to pick differently sized items like beef jerky or French toast sticks off conveyor belts and place them in packages or onto other equipment for further processing. Prior to the addition of machine vision, robots had difficulty identifying and handling items that came in a variety of sizes. |

| Sandwich assembly | Robots are currently being employed in sandwich assembly applications where they can select multiple, different items, such as bread, sausage and a precooked egg or several varieties of deli meats and other ingredients, and assemble them in the proper order to create a sandwich that will be frozen or offered as a pre-made meal. While this is an easy application for human workers, on a large scale of thousands of sandwiches per shift, it is repetitive, tedious and more time consuming to accomplish manually. |

| Bakery applications | Robots can be used for cutting and slicing bread, pre-portioning cake slices and picking and placing soft and delicate bread, buns and baked goods on conveyors or baking racks for large-scale bakery processes. |

| Product decorating/dispensing | Thanks to machine vision and advanced end effectors, robots can be employed in cake decorating processes, even those that involve intricate designs. Similar applications include adding sauce and/or toppings to pizza crusts for frozen pizzas, garnishing prepared meals and branding chocolate. While these tasks can be accomplished by humans, the efficiency of a robot is unparalleled and robots are able to create consistent patterns and designs every time, which enhances product quality. |

As these and other applications become automated throughout the food industry, it will enhance facility safety and product quality and allow human workers to contribute to more value-added tasks throughout the plant, while also helping food processors achieve more throughput thanks to the speed and efficiency of robots.

For more information on automating food processes with robots or automated systems, please contact JHFOSTER.