5 Applications of Robots That Have Revolutionized Manufacturing

Industrial automation and robotics have revolutionized the manufacturing industry as these technologies help increase efficiency, throughput and productivity, while also offsetting labor shortages, boosting facility safety and enhancing product quality. Because robots offer so many impactful benefits, they provide a competitive edge for manufacturers who strive to produce more product at a lower cost.

While different types of robots have been applied successfully to a myriad of applications ranging from dicing food to dispensing adhesives to filling warehouse orders, this blog will showcase 5 common industrial applications for robots that can be applied to virtually any production line with dramatic efficiency-boosting and cost-cutting benefits that have revolutionized the manufacturing industry.

The Advantages of Industrial Automation and Robotics

Before discussing common applications of robotics, it’s important to understand the key benefits that industrial robots bring to the table in almost every function to which they are applied.

Increased efficiency

Industrial robots are designed and built to operate at high speeds so they complete tasks significantly faster than human workers. In addition to boosting the speed of the process, robots work continuously without breaks and without becoming fatigued, further increasing productivity and output. And, because their high speeds allow them to keep pace with the task at hand, the application of robotics often eliminates troublesome bottlenecks. All these factors come together to provide greater efficiencies and higher levels of throughput for the entire production line.

Enhanced facility safety

Since industrial robots can safely replace human workers in areas that are considered high-risk environments, the application of robotics reduces the health and safety risks associated with working in hazardous locations. In addition, robots can be applied to tasks that require heavy lifting, bending and twisting or those that require the handling of sharp objects, decreasing instances of repetitive motion and other injuries.

Better product quality

Because robots are programmed to perform a task or sequence of tasks to exact specifications, they provide higher levels of accuracy and precision than human workers. In addition, robots manage tasks in the same manner every time, eliminating instances of human error or variations between employees and ensuring that products are reliably manufactured to the same specifications every time. These attributes ensure product quality.

Minimized costs

The installation of robots encourages cost savings by increasing efficiency, reducing waste associated with products that do not meet quality standards and minimizing costs associated with accidents and injuries in the plant.

When the advantages of industrial automation and robotics are spelled out, it’s easy to see why there is a growing trend toward installing robots on the plant floor.

5 Common Industrial Applications of Robotics

So, without further ado, here are five common robot applications that have revolutionized the manufacturing industry:

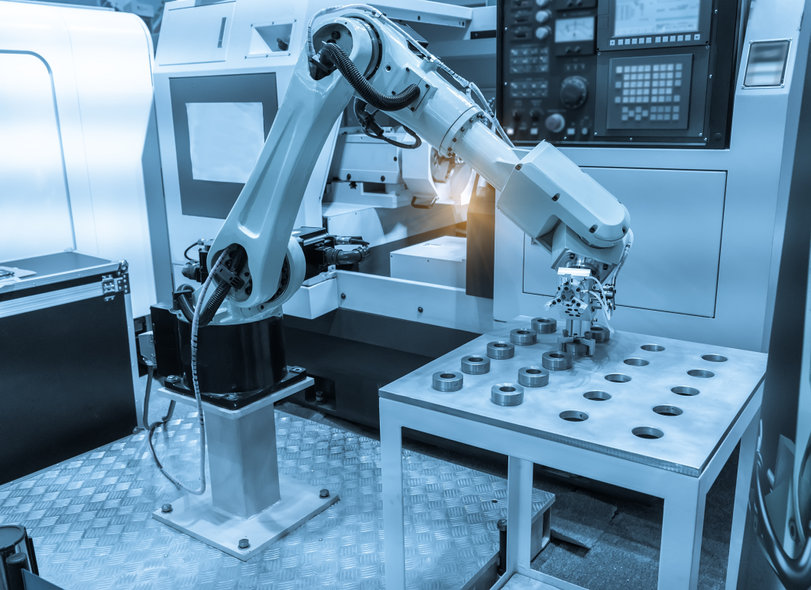

- Assembly and Sub-Assembly: The addition of robotic assembly solutions helps to eliminate bottlenecks, as well as wasted product and materials, because robots equipped with grippers offer great dexterity and can be programmed to work continuously at high speeds while maintaining high levels of accuracy. Robots are ideal for assembling products in industries including the automotive, electronics, medical device, food processing and other applications that necessitate high speeds and demand great levels of precision.

- Material Handling: Because robots can lift and move heavy loads at high speeds, they are ideally suited for material handling operations that require loading and unloading bulky or heavy packages of raw materials, parts or equipment on and off production lines, conveyors, packaging operations and other manufacturing floor settings. Applying robots in this manner frees up human workers to complete more value-added tasks, reduces the risk of workplace injuries and speeds up the entire process.

- Welding: Typically a labor intensive, dangerous and highly specialized task, welding is an ideal application of robotics. Robots can be programmed to perform arc, TIG, MIG, plasma or spot welding in automotive manufacturing or other industrial applications. Using robots in welding applications helps reduce risks to human workers who can be burned or inhale fumes, while also ensuring that the task is completed to exact specifications.

- Picking, Packing and Palletizing: Almost every industry requires the picking, packing and palletizing of their goods. This can be a time-consuming and labor-intensive job for human employees and carries a high risk of causing musculoskeletal injuries due to the associated repetitive motions. Individual pick and place robots can be used for bin picking, packing robots can be applied to packing lines and palletizing robots can be added to palletizing operations, or a single robot can be programmed to provide a sequence of operations that involve picking products, packing them and then loading them to a pallet for storage or shipment. Using robots for these operations reduces injuries, enhances efficiency, prevents bottlenecks, minimizes errors and frees workers to perform value-added tasks elsewhere in the facility.

- Quality Control/Inspection: Robots can be programmed to select and hold a component or product in front of a stationary camera for inspection or hold a camera and move it around the object so that images can be used for inspection purposes. More recently, the integration of machine vision technology and industrial robots have been applied to quality control and inspection operations, where the robot can be programmed to pick up an object and use integrated machine vision technology to “see” and analyze the object to ensure that it meets quality specifications. The same robot can be programmed to place the object back on the conveyor if it passes inspection or move it to another area if it is not up to standards. The addition of robotics in this industrial application goes a long way toward increasing product quality as robotic inspection is less subjective than human inspection and machine vision has a greater ability to accurately detect miniscule flaws than does the human eye.

While different types of robots may be used for a wide variety of industrial applications such as painting; machine tending; cutting grinding and deburring; spraying; end of line packaging; and other activities in a variety of industrial settings, these five common use cases are proven solutions that are likely to provide a quick return on investment as they greatly enhance efficiency, productivity, safety and product quality in almost any manufacturing operation. JHFOSTER is standing by to assist you with the application of robotics in your facility.