Month: May 2025

Revolutionize Facility Cleaning with an Industrial Robot Vacuum

Manually cleaning the floors in a manufacturing plant, warehouse or any other large industrial facility is a time-consuming, but necessary evil. However, industrial robotic vacuum cleaners can get the job done quickly and effectively, freeing employees to perform more value-added tasks around the facility. This blog will explore the ways in which industrial robot vacuums […]

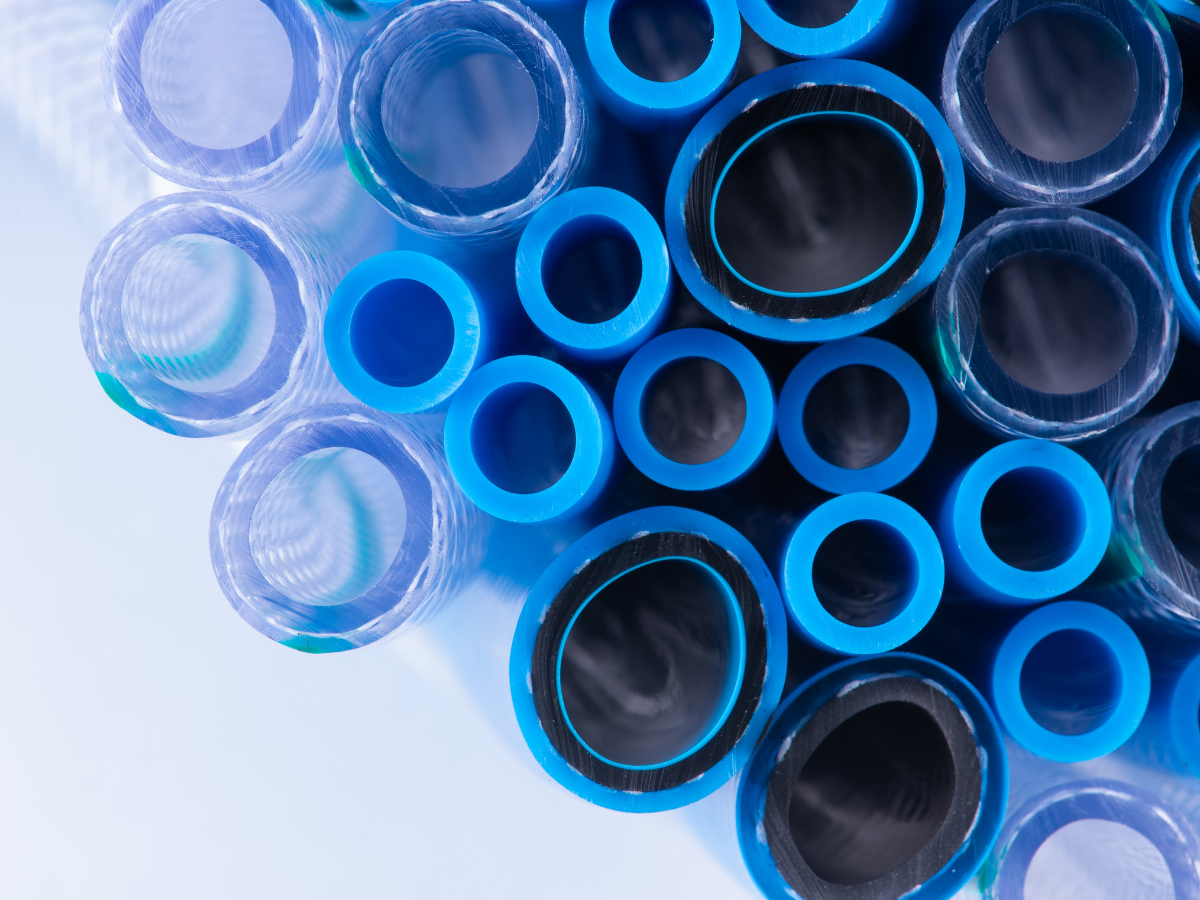

Choosing the Right Compressed Air Tubing for Pneumatic Applications

Compressed air is used in thousands of applications in industry. And, while much focus is placed on the big-ticket components within pneumatic systems, compressed air tubing isn’t something that gets much attention. Despite this, it is an essential part of pneumatic systems because it delivers air from the main compressed air distribution system to where […]

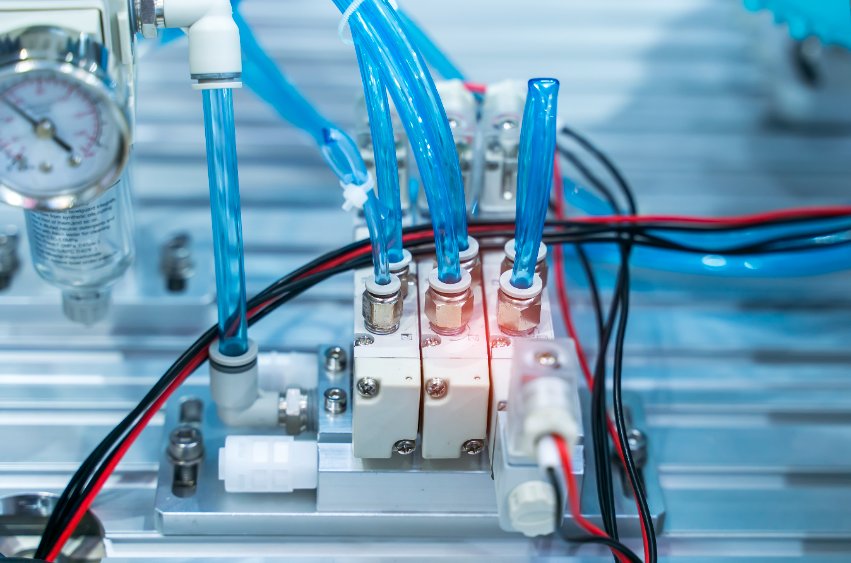

Boost Machine Efficiency with Pneumatic Valves

Pneumatic systems play an essential role in today’s manufacturing industry. Pneumatically driven equipment includes critical process equipment, automated systems, manufacturing machinery, packaging and bottling lines, material handling machines and conveyors, industrial robots, machine tools and more. The pneumatic systems that drive industrial equipment operate using air pressure, but for pneumatic systems to be effective, there […]

6 Benefits of a Closed-Loop Air Compressor Cooling System

During daily operation, air compressors generate a lot of heat that can damage nearby equipment, injure employees and have a negative impact on finished products. For water cooled compressor installations, an air compressor cooling system is an essential component because it removes excess heat to ensure consistent, safe and efficient air compressor performance. When selecting […]

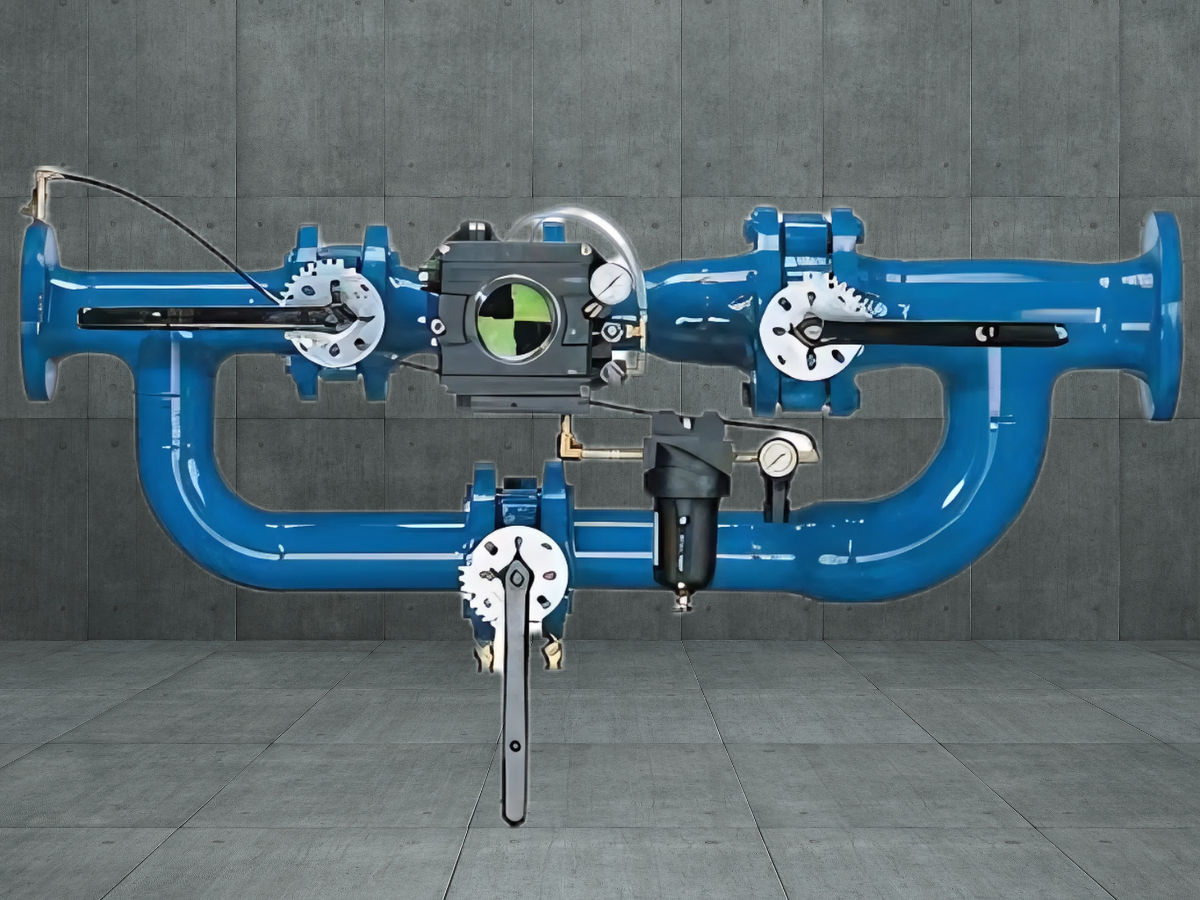

6 Reasons to Avoid Galvanized Pipe for Compressed Air Lines

Piping is a critical component of the compressed air delivery system as its purpose is to efficiently and safely transport air to the points of use, such as pneumatic tools, machinery and automation. For this reason, compressed air pipe must be tough enough to withstand high pressures, resist corrosion and be easy to install and […]

7 Ways Pressure Flow Controls Optimize Pneumatic Systems

While most facilities with properly sized air compressors should have an adequate supply of air to power their automated pneumatic systems, problems may arise during fluctuations in demand and times of peak usage when air demand exceeds capacity, causing unstable system pressure. In response to fluctuations, the pneumatic system can overcompensate and boost system pressure […]

5 Ways to Use SCADA Automation for Compressed Air Monitoring

Compressor monitoring is a great way to optimize compressor efficiency and coordinate maintenance plans. And, when operating a multi-compressor installation, users may find they need a more centralized compressed air monitoring control platform. Fortunately, Supervisory Control and Data Acquisition (SCADA) systems, which combine hardware and software technologies for the monitoring and control of industrial equipment […]

Proper Equipment and Compressed Air Quality Testing Assure Clean Air

High-quality compressed air is a necessity in most industries – and some in particular, such as food and beverage, pharmaceuticals and medical device manufacturing, must meet stringent ISO quality testing guidelines to safeguard the purity of their compressed air. Installing top-notch air compressors and components and regularly conducting industrial air quality testing will help ensure […]