Month: April 2025

Top Safety Considerations for Robotic Systems Integration

When planning a robot or automation integration project, most businesses focus on the anticipated productivity gains; however, because robots and automated equipment are fast-moving machines and are often located in the busiest areas of the facility, industrial robot safety should receive equal attention in order to keep the workplace as efficient and safe as possible. […]

Designing the Ideal Environment for Your Air Compressor Room

While selecting the right industrial air compressor is critical for efficient and effective performance, it is only part of the equation. The compressor room environment, air compressor system design and compressor installation also play a crucial role in the operation of the compressed air system. Important considerations for air compressor room design, system design and […]

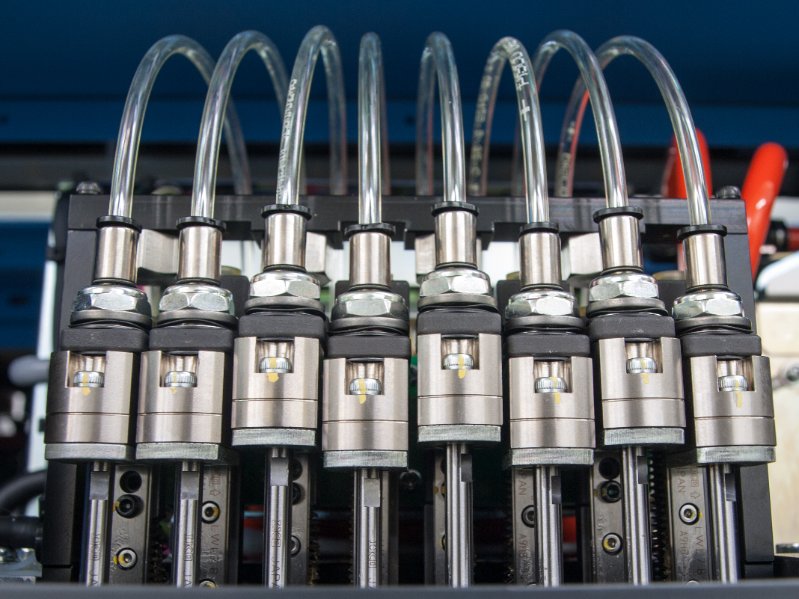

Optimizing Pneumatic System Design for the Best Performance

In pneumatic systems, pressurized air generates motion that is used to drive automated equipment, manufacturing processes and air-powered tools and devices in a reliable and cost-effective way. But to achieve top-notch performance in any application, properly designed air systems are a must. This blog will explore and explain pneumatic systems and how careful selection of […]

Understanding Air Compressor Duty Cycle Optimizes Performance

Duty cycle is a term that may come up when sizing an industrial air compressor. Although there is no standard definition used by air compressor manufacturers to rate air compressor duty cycle, understanding a unit’s duty cycle can go a long way toward ensuring that the compressor offers the correct size and performance for the […]

7 Considerations for Choosing the Best Robot End of Arm Tooling

Automating with robots and cobots can greatly increase the efficiency of a manufacturing operation. And, when properly chosen, the right robot grippers or tooling can further improve the performance of automated systems because outfitting a robot with the most appropriate end of arm tooling (EOAT) allows for a more precise robotic grip and enables more […]

Comparing Types of Vacuum Pumps, Benefits and Applications

Because vacuum pumps are used throughout the manufacturing sector, there are many types of vacuum pumps available to accommodate the wide range of industrial applications. While choosing the right vacuum pump can be challenging, selecting the most suitable technology is critical to achieving the best operational efficiency and performance. To simplify the selection process, we’ll […]

Five Ways Proof-of-Concept Testing Prevents Costly Failures

Before any large investments are made in industrial automation projects, management will likely want a deeper understanding of the application, the equipment, the engineering design, the benefits and the automation ROI. One way to provide this critical information is to conduct a preliminary demonstration that verifies that the project will increase efficiency, productivity, safety and/or […]

Five Reasons to Use Proportional Valves for Precise Flow Control

In pneumatic applications where the output may vary, a proportional valve can be a great solution because proportional valves are designed to change the output pressure or flow to match that of the input to provide a consistent output performance. With a fast, precise response to changes, air proportional valves quickly achieve a stable flow […]