Month: September 2024

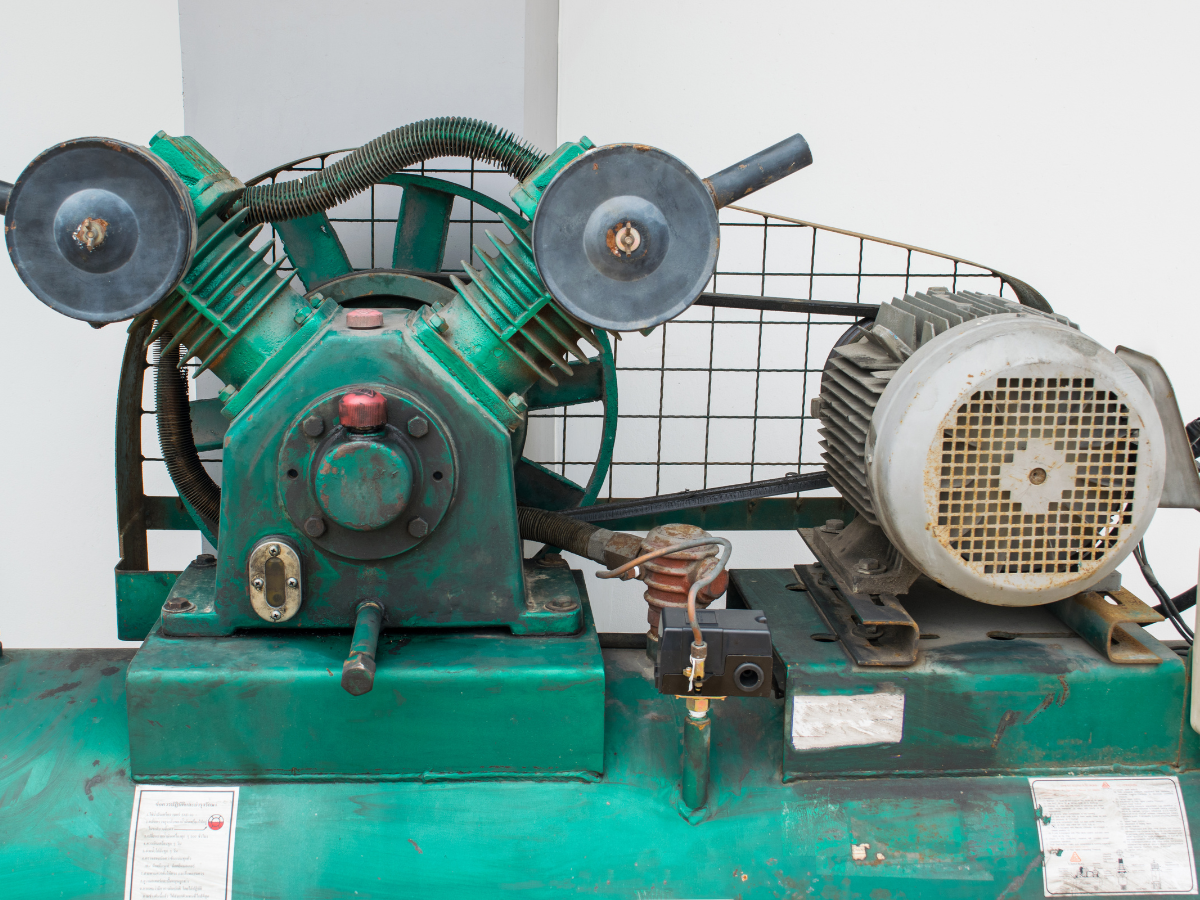

The Anatomy of Reciprocating Compressors

Air compressors are integral to most facilities where compressed air is used to power pneumatic tools and machinery and may be used directly in the manufacturing of products. Because there are so many different applications and facilities, there are several types of air compressors available to suit various needs. Here we will explore reciprocating compressors, […]

Compressed Air Audits Optimize Systems and Provide Quick ROI

Every dollar counts these days, so manufacturers are seeking ways to slash unnecessary spending. Because compressed air systems consume a lot of energy, optimization via a compressed air audit that zeroes in on areas of waste and provides recommendations aimed at lowering compressed air system energy consumption can provide significant savings with a quick return […]

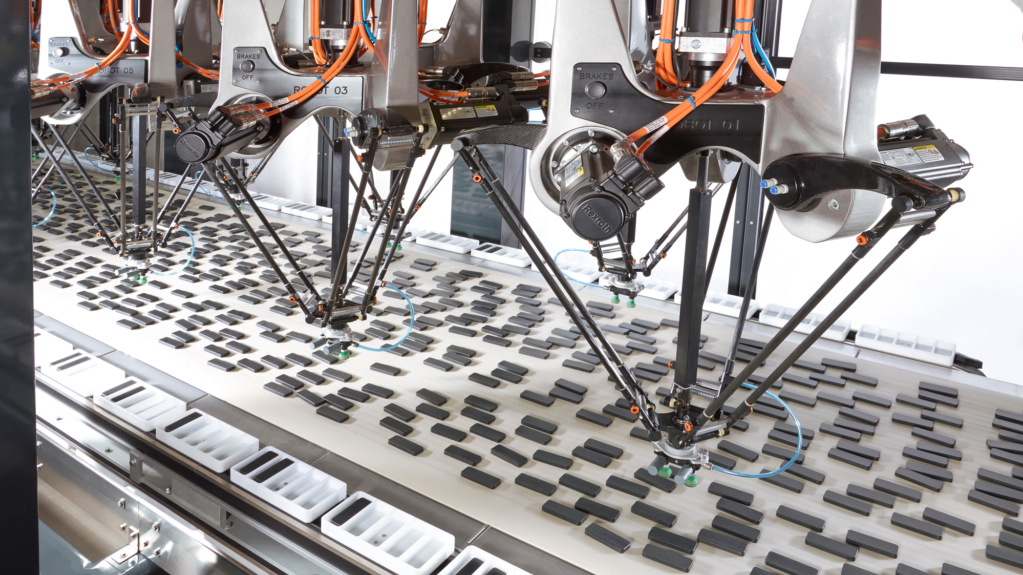

The Role of Robotic Arms in Modern Manufacturing

Robotic arms serve as the highly efficient “hands” of automated machinery in manufacturing operations. Developed to make tasks that were previously managed by human employees significantly faster, more accurate, highly repeatable and safer when properly integrated, robotic arms have revolutionized the modern manufacturing industry. This blog will explore the benefits and mechanics of robotic arms, as […]

Achieving ISO 8573-1 Compliance for Compressed Air Quality

Compressed air is a staple in industry and is used for everything from powering air-operated tools and equipment to processing and packaging food and other products. While many facilities are concerned about the energy efficiency and performance of their compressed air system as it directly impacts the bottom line and productivity of the plant, compressed […]

Choosing the Right PLC Programming Language for Your Automation Projects

While there are many PLC programming languages available for industrial automation projects, two of the most commonly used are ladder logic and function block diagram (FBD). Choosing which to use often comes down to personal preference or experience with one language or the other; however, each PLC language has advantages and disadvantages, which this blog […]

How to Size Compressed Air Piping

The compressed air piping system has a direct impact on the overall performance and efficiency of an industrial air compression system, making proper sizing of air compressor lines especially critical in system design and operation. Inaccurate compressed air pipe sizing will result in inefficient – and expensive – delivery of the air from the compressor […]

Reduce Waste and Increase Efficiency with Lean Manufacturing Techniques

In today’s highly competitive manufacturing environment, many businesses are considering employing lean manufacturing techniques to reduce waste and operating costs while improving product quality and efficiency. But what is really involved in lean manufacturing, what are the advantages and how is it implemented? This blog will discuss the principles of lean manufacturing systems, the types […]

Versatile Applications of Air Compressors Between 5 and 15 HP

A lot of attention is given to large air compressors – and for good reason: they serve as the heartbeat of industrial facilities as they power robotics end of arm tooling, automated air-powered equipment and industrial tools. However, there are a lot of applications that can be served by smaller units, such as 5 hp […]