Month: January 2024

10 Impactful Benefits of Proper Safety Guarding

Industrial facilities are active places and host a variety of risks – from slips and falls to hazardous chemical use and storage to traveling forklifts to machinery with moving parts – that can injure or potentially kill employees. Accidents caused by these and other dangers can not only incapacitate workers, but they can also result […]

Advanced Scan Tunnels Boost the Performance of Package Handling Operations

Due to a lasting uptick in online shopping and home delivery, packaging facilities, warehouses, e-commerce businesses and distribution and fulfillment centers continue to feel pressure to boost efficiency and sort more packages each day while reducing costs and maintaining high levels of accuracy. Advances in scan tunnel technologies, such as the ability to quickly read […]

Reap the Benefits of Asset Monitoring with a Simplified Solution

Smart manufacturers know that monitoring plant assets is essential to maximizing productivity, minimizing downtime and optimizing equipment usage. Fortunately, current solutions drastically reduce the time and effort needed to conduct effective asset monitoring, making the benefits easily accessible to manufacturers big and small. This blog will highlight the advantages of asset monitoring, discuss use cases […]

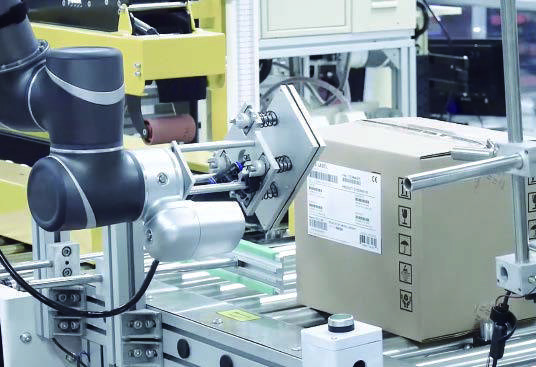

Automation Optimizes Medical Device Packaging and Palletizing

Just as in the manufacturing of medical devices, end-of-line packaging and palletizing of products intended for patient healthcare must also meet strict governmental regulations. At the same time, to remain competitive, packaging and palletizing of these sensitive products must be done efficiently and cost effectively. Fortunately, there are automated options available that not only boost […]

Automated Machine Tending Improves Medical Manufacturing

While all manufacturers need to improve efficiency and cut costs to remain competitive, the stakes are higher for medical manufacturers as they also need to maintain tighter manufacturing tolerances and adhere to stricter regulations regarding sterility, safety and consistency. Automated machine tending can help medical manufacturers tick all the necessary boxes while also boosting speed […]

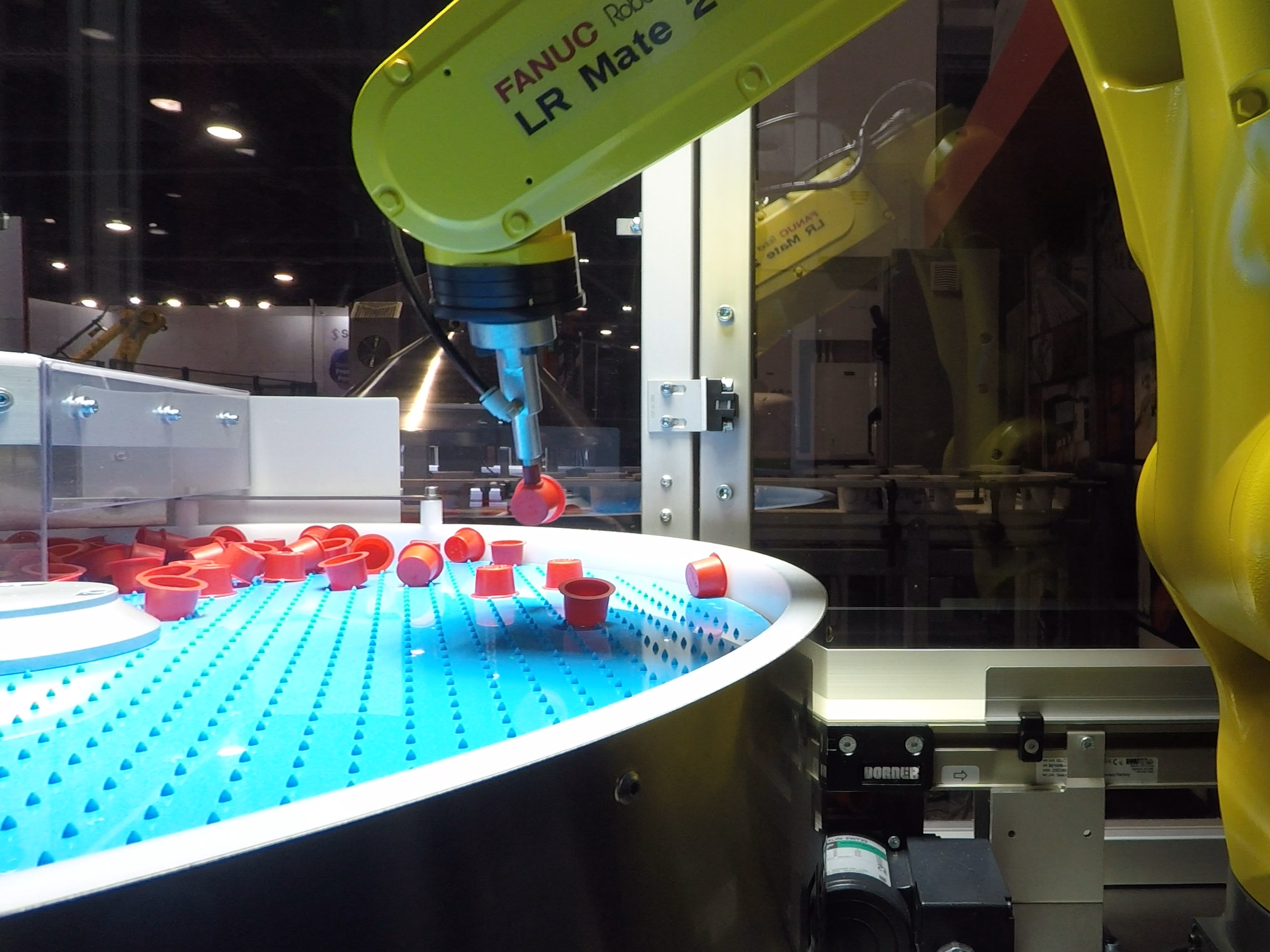

The Automated Flex Feeder System Advantages over Bowl Feeders

Faced with mounting pressure to improve efficiency, accuracy and quality, many manufacturers employ automated feeding systems to further boost throughput and reduce the burden on manual laborers. Automated feeding systems enhance productivity because they quickly separate bulk parts and place them in the proper orientation so they are consistently fed onto an assembly or production […]

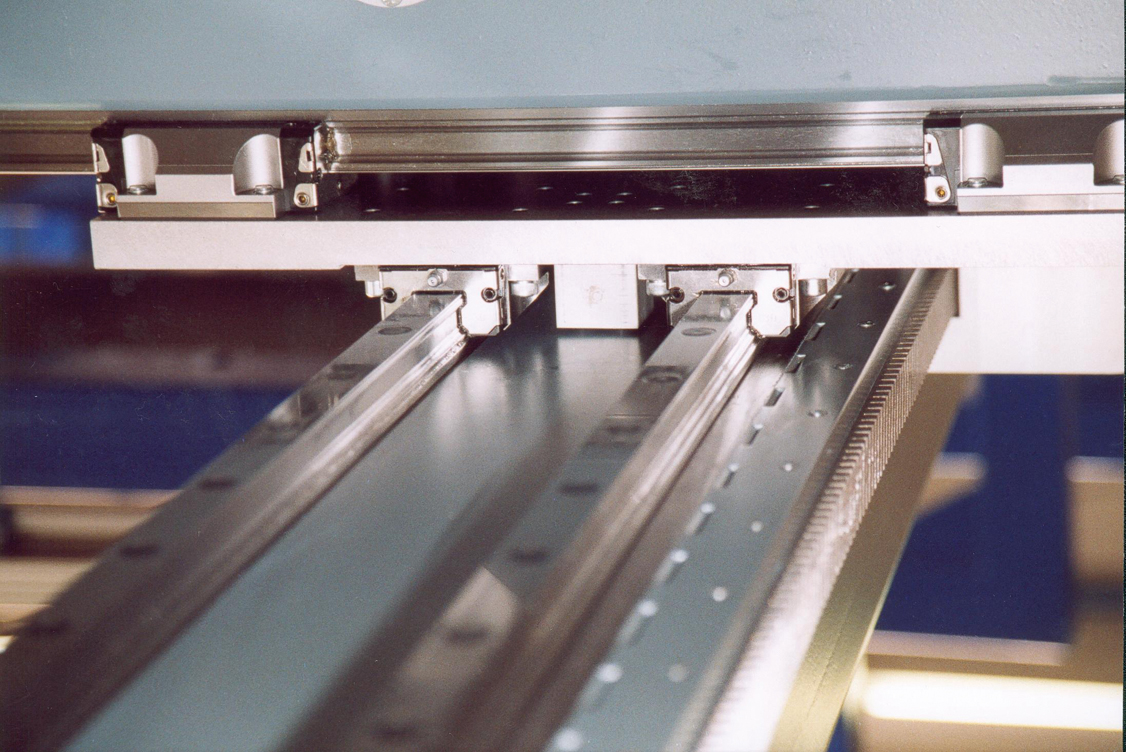

A “Straight” Forward Reference on Linear Guides

Linear guides are mechanical systems used to support and carry loads, while also ensuring straight and level linear movement of components within a wide variety of devices and machinery. While there are many types of linear guides, the goal of any linear guide system is the same: to provide smooth, low-friction motion in applications that […]

The Next Wave: Industry 5.0 Encourages Human-Centric Automation

By now most manufacturers are familiar with and, likely, active participants in Industry 4.0, which combines Internet of Things (IoT)-based technologies, automation and data analysis to squeeze every last drop of productivity from the factory. The next wave – the Fifth Industrial Revolution (Industry 5.0) – builds upon this foundation of sensors, automation and Big […]

Actuators: Creating Movement in Manufacturing

The factory floor in most manufacturing facilities is a very active place. From the front door to the back, there is likely a whirlwind of motion and movement as automated machinery transports, picks, cuts, stamps, assembles, processes, produces and packages products. While it may seem like all of this productivity is controlled with the touch […]