Month: March 2022

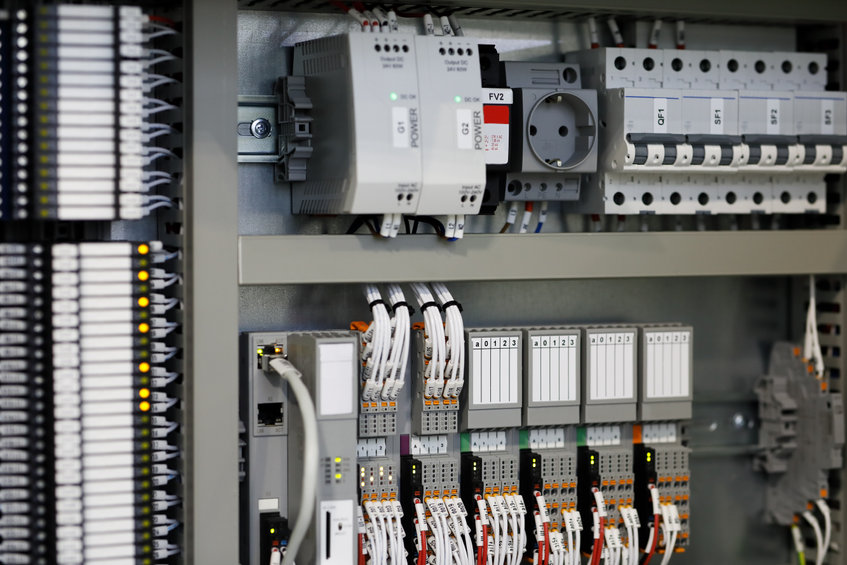

A Guide to Electrical Control Panels

If a product came from an automated assembly line, then an electrical control panel was involved in controlling it. This means anyone reading this has encountered a product made with the help of a control panel. An electrical control panel is a system of several electrical devices that control and monitor the mechanical functions of […]

When Do Air Compressors Need Filters?

Seventy percent of all manufacturers use some type of compressed air system. Air compressors produce tighter, and more pressurized air to generate a steady stream of airflow. This airflow is then used to power a variety of tools, assembly lines, and pneumatic equipment. Compressed air is crucial to many industrial and manufacturing processes. If contaminated, […]

Why and How Industrial Automation Is the Future

Put simply, industrial automation is the future. With increased labor needs due to product demand and open positions, automation is the answer for many industries. From manufacturing to breweries, automation is proving to be the ideal coworker for many employees. Rather than taking jobs, automation is filling the need for dirty, dull, and dangerous jobs […]

How to Build Your Automation Roadmap in 7 Steps

There is no question that automation is becoming increasingly essential for businesses across different industries. According to Forbes, companies continue to increase their investment in automation technologies for operations, customer service, finance, and other processes. Automation is being maximized for a wide range of benefits, including increased productivity, improved safety, and better product development. However, […]

How to Remove Contaminants in Compressed Air

Today, virtually all industrial chemical processes use or interact with compressed air systems. Air compression is required in most processes, whether to add texture to products, dry sterilized equipment, divert items and ingredients along the assembly line, or perform a whole range of other tasks. Throughout all these processes that use compressed air systems, contamination […]

Saving Energy With Pneumatic Valves and Smart Sensors in Packaging Lines

Written by the specialists at Emerson. It’s estimated that more than a third of greenhouse gas emissions are produced by food systems, with packaging processes responsible for around 5.4% of that. To reduce — and ultimately eliminate — emissions, consumer packaged goods (CPGs) companies are setting decarbonization targets. As CPGs take action and move toward […]

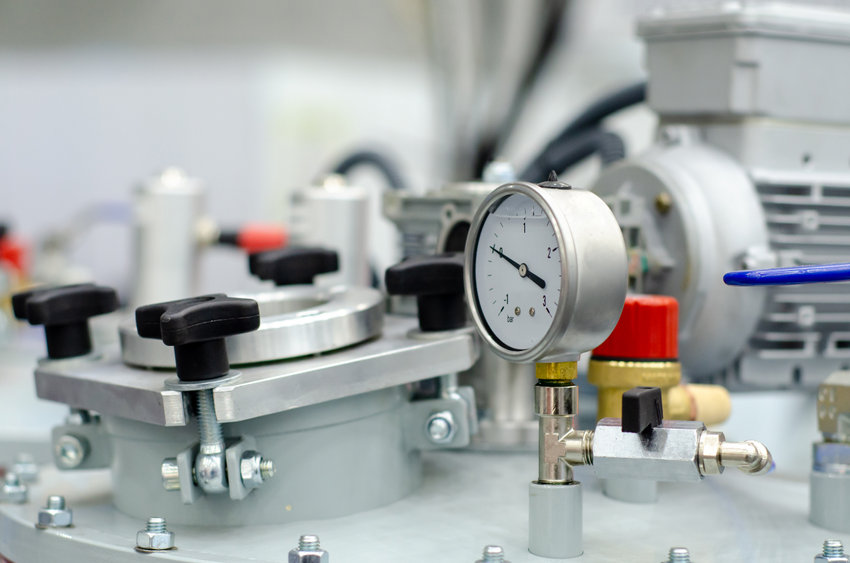

The Different Types of Industrial Air Compressors

Compressed air is an essential energy source for the industrial sector. It is often used to power pneumatic tools and automate key equipment. According to the U.S. Department of Energy, approximately 10% of the electricity consumed by an industrial facility is used to generate compressed air. For some plants, compressed air generation may account for […]

The Dangers of Dysfunctional Actuators

Actuators help streamline manufacturing processes while lowering production costs. However, issues and defects in these components can jeopardize the entire production line and result in severe downtime. In manufacturing, downtime can translate to significant financial losses. It is estimated that downtime causes every factory to lose at least 5% of productivity, with some factories losing […]

Maximizing Efficiency in Motion Control Systems

Experts predict that by 2025, 10-15% of jobs in three sectors, namely transportation, manufacturing, and retail trade, will have high potential for automation. As more companies adopt automated processes and technologies, the demand for motion control systems in factories and production lines has grown exponentially. Motion control systems make sure that products are assembled successfully […]

Why and How To Perform A Vacuum Audit

Vacuum holds material in place, gathers up solids and liquids, provides transport, and keeps chambers and enclosures free from gases that would affect process performance. It’s essential in many production operations and a system that’s performing badly will impact costs and quality. Regular vacuum audits provide insight into how a system is running and identify […]