Tailoring Injection Molding Solutions for the Food and Beverage Industry

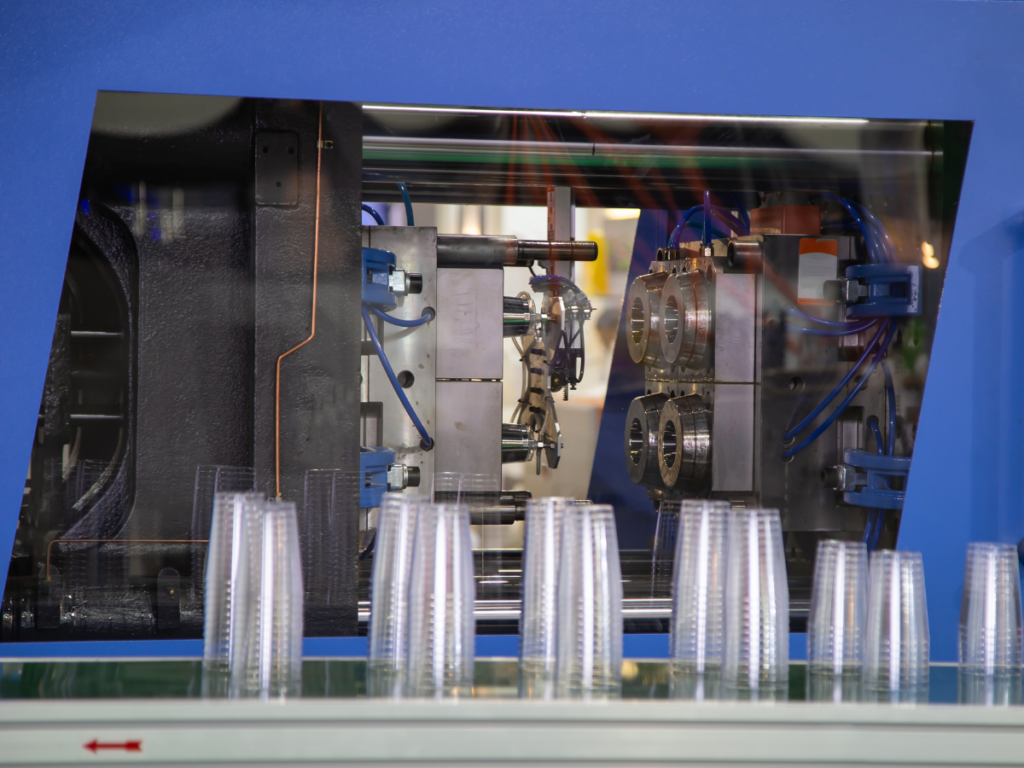

From juice bottles to peanut butter jars, injection molded products are found throughout the food and beverage industry. The unique needs of this manufacturing sector, as well as current food and beverage industry trends, make food processing an ideal candidate for customized plastic injection molding machinery and plastic injection molding tooling.

Injection Molding Solutions Solve Food and Beverage Challenges

Injection molding techniques are widely used in the processing and packaging of food and beverages because injection molded plastics protect and preserve foods during shipping and when on the shelves, while the process itself provides an extremely efficient method for mass producing food-safe bottles, jars and containers that meet the demands of today’s sustainability trends.

Here are a few ways in which injection molding solutions solve food and beverage industry challenges:

| Increased efficiency | Plastic injection molding machines offer efficient high volume production of containers and bottles used throughout the food and beverage industry and do so in a cost-effective way, allowing processors to increase throughput and save revenue. Increased diversity of product: Because there are many different food products, there is a need for creating bottles and packing in a range of shapes, colors and materials. Injection molding machines can be used to safely create food-safe plastic caps, bottles and containers that are transparent or offered in a variety of colors, depending on the needs of the application. Injection molded plastic products can be made to be temperature resistant for food preparation or storage, as well as impact resistant to safely preserve contents during shipment and storage. |

| Promote sustainability | One of the hottest food and beverage industry trends at the moment is sustainability, both in packaging and processing. Injection molding solutions tend to be eco-friendly as they reduce waste during the process. The ability to injection mold plastics that are recyclable, biodegradable or compostable further supports the industry’s sustainability efforts. And, because the proper packaging protects and preserves the food it contains, it also helps reduce food waste by ensuring products reach consumers without damage or spoilage. |

| Ensure compliance | Plastic injection molding companies that regularly work with food and beverage processors have experience in providing injection molded plastic products that meet necessary specifications and Food and Drug Administration (FDA) regulations regarding food processing practices and food-safe plastic materials to help ensure compliance. |

Injection Molding Solutions Used for Food Processing MachineryIn addition to using injection molded bottles, caps, jars and other containers used to store, ship and serve food, injection molding solutions can be used to customize the food processing machinery itself.

Because injection molding companies are capable of producing incredibly detailed parts, the technique can be used to create customized solutions for food processing machinery. Injection molded plastic components can be fitted into machines that process poultry, fish or meat, as well as conveyor belts that move bulk products through the facility or finished products along bottling or packaging lines. This is especially helpful when handling delicate food items, as injection molded machinery components tend to provide gentler handling than the metal parts they replace on food processing machinery.

Tailoring Plastic Injection Molding Solutions for the Food and Beverage Industry

In order for food and beverage manufacturers to achieve the benefits provided by injection molding techniques, they may need to tailor injection molding machinery to suit their individual purposes. Often this involves integrating customized solutions, such as feeder systems for insert molding or robots that are capable of high-speed parts removal from plastic injection molding machinery.

Integrators with injection molding machinery and food and beverage industry experience, such as DevLinks, a Tavoron company, can assist with tailoring and customizing injection molding solutions to meet the demands of any food and beverage application. Reach out to JHFOSTER, a Tavoron company, today to learn more about the ways injection molding can help meet the needs and overcome the challenges of the food and beverage industry.