How to Select the Right Gearbox for Your Application

With many different gearbox types available, selecting the right one can be a challenge but the most suitable gearbox for your application will provide the most efficient and cost-effective performance. Proper gearbox selection requires determining how the gearbox must perform and how it will be mounted. This blog outlines the selection process.

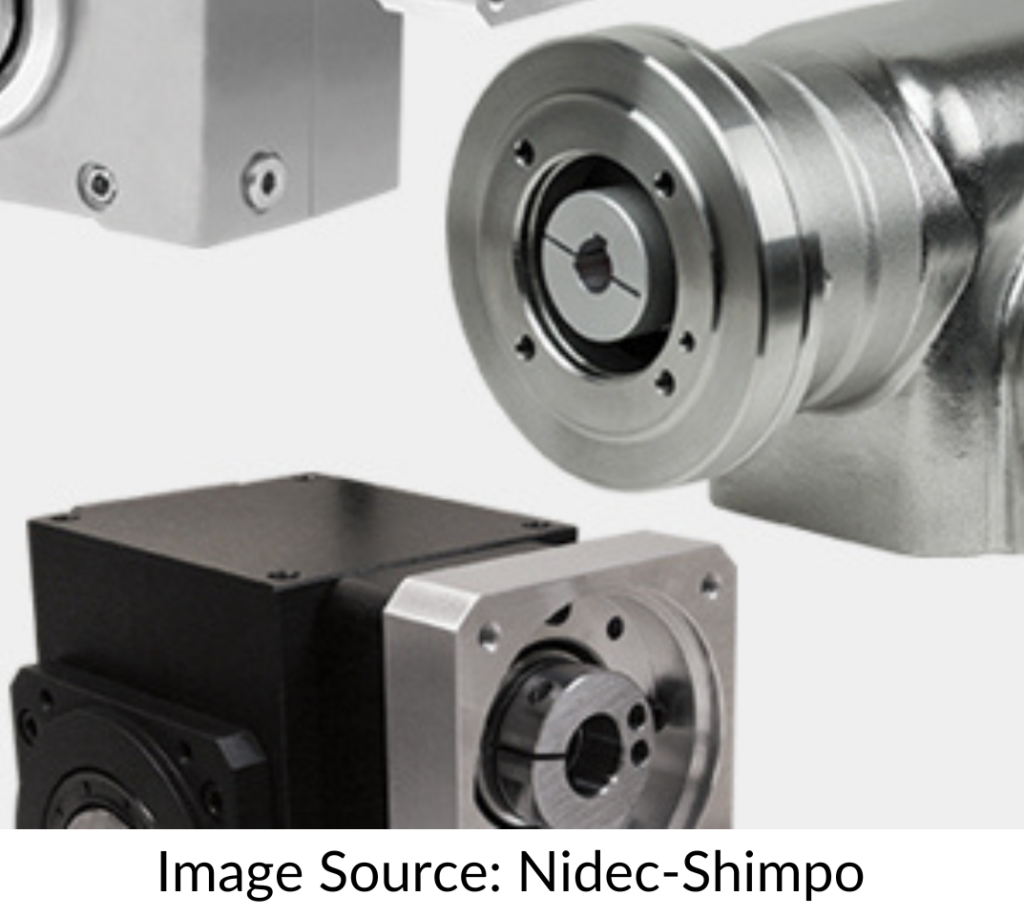

Gearbox Types

Industrial gearboxes are devices that transmit mechanical power. They are used in a wide variety of industrial equipment. They are comprised of an enclosed housing containing a series of gears, shafts, and bearings. They provide smooth, precise changes in speed, torque, or direction. They are found in various industries such as manufacturing, automotive, food and beverage, pharmaceutical, material handling, printing, and others.

The most common types include:

Helical Gearbox: This gearbox has gear teeth that are cut at an angle, which prolongs the contact between the teeth during operation to reduce noise and vibration and allows the input and output shafts to be either parallel or perpendicular.

Coaxial Helical Inline Gearbox: This type of gearbox has parallel shafts and compound helical gears and is used in applications where a large range of speeds and torques are required, such as automobile transmissions.

Spiral Bevel Gearbox: The spiral bevel gearbox has perpendicular input and output shafts and curved gear teeth that are cut on a slope, allowing them to run more smoothly than others.

Planetary Gearbox

This gearbox contains a central “sun” gear surrounded by several “planet” gears inside of an outer ring gear with internal teeth. Because the power is spread out equally between the gears, this type of gearbox can achieve very high torque or very high speed in a very small package.

Worm Gearbox: This type of gearbox features a worm wheel with teeth that mesh with a screw-like worm. They produce very high torque and only allow power to flow from input to output.

Gearbox Selection Steps

- Identify Output Style: Determine if you need the input shaft and output shaft to be parallel, co-linear, at different angles, and/or on different planes. Also, decide if you need a sprocket, toothed pinion, pulley, or other items on the output shaft. Most of these items create a high radial load.

- Consider Shaft/Hollow Bore Size and Features Options might include keying, splining, shear pinning, tapering, static grounding, etc.

- Determine Load Type: Non-uniform loads and high-shock loads often require a higher service factor because they increase wear on gears and bearings.

- Determine Load Values: Calculate the axial (thrust) loads and radial (overhung) loads that will be acting on the output shaft of the gearbox and check the gearbox manufacturer’s catalog to find one that can withstand them.

- Analyze Gearbox Mounting Needs: Most gearbox manufacturers offer a range of mounting configurations. Some of the most common mounting options include mounting feet for either above or below the body of the gearbox, hollow outputs, and many different input and output configurations. Housing styles may limit how a unit is mounted, so custom frames or brackets may be needed.

- Define the Service Factor: The service factor is defined by the AGMA (American Gear Manufacturers Association) as the ratio between a specific gearbox’s rated horsepower and the horsepower demanded by the application. It is based on the conditions of the application, the type of gearbox, and the expected hours of operation per day.

- Evaluate Temperature and Environment: This will determine if special sealing materials and corrosion-resistant materials are needed, and it will help determine lubrication requirements.

- Other Considerations: Sometimes manufacturers must ship the gearbox without lubricant due to regulations about the transportation of hazardous materials, and some manufacturers may offer to integrate a motor onto the gearbox and ship the assembly as a single unit.

While it is a lot of information to consider, improper selection of a gearbox may result in a gearbox that is overkill in the best-case scenario or one that fails prematurely in the worst case. Proper selection will result in optimal operation and long service life in the application.

For help sizing and selecting a gearbox, please reach out to an expert at JHFOSTER.