Overcome Human-Robot Collaboration Challenges with an Expert Partner

Human-robot collaboration (HRC) is a powerful way to improve productivity, efficiency and safety, but integrating robots into a human workforce presents unique challenges. As your experienced automation partner, JHFOSTER can help you navigate HRC integration complexities so you can start operating smarter and more efficiently.

What Is Human-Robot Collaboration (HRC)?

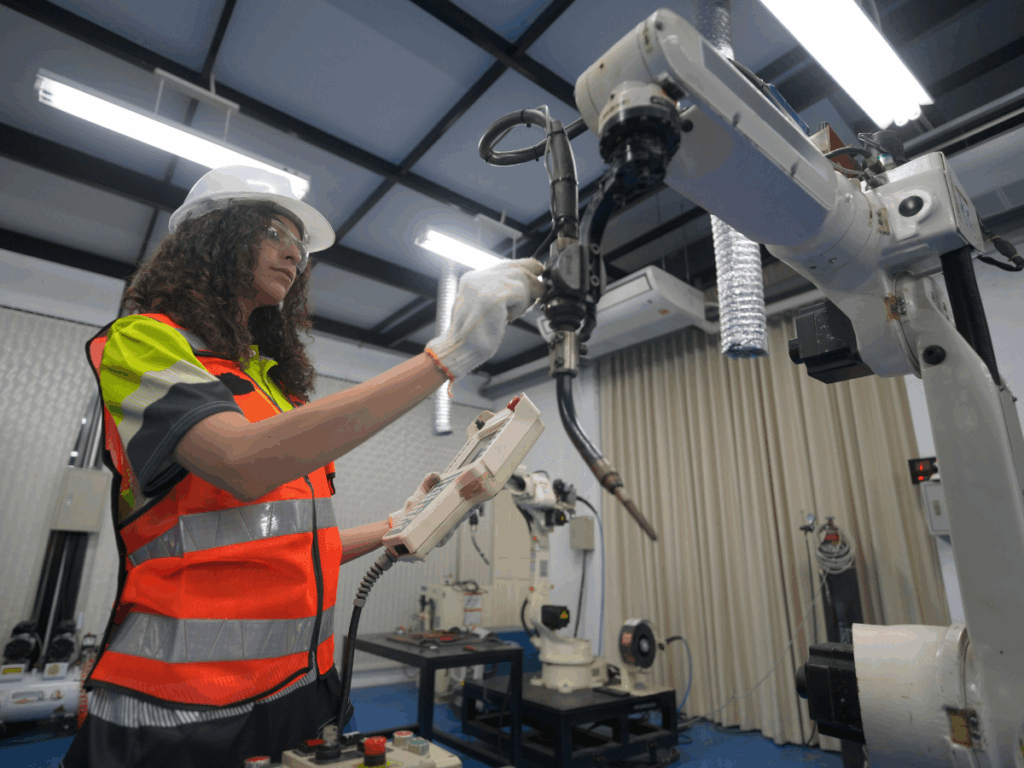

HRC is a process in which humans and robots share a workspace to complete tasks, combining the robot’s strength, speed and precision with human intelligence, dexterity and problem-solving skills.

Collaborative robots, or cobots, are robots that are specially designed for safe operation around humans to enable productivity-enhancing human-robot collaboration. Although cobots feature built-in safety functions that allow them to work alongside people without traditional safety fencing, conducting a risk assessment is still required.

4 Key Challenges in Human-Robot Collaboration and How We Solve Them

Increased efficiency, higher quality and a better safety record are all benefits of HRC, but successful installation depends on overcoming several key challenges. As your automation partner, JHFOSTER provides tailored solutions for each challenge.

Ensuring Worker Safety and Compliance

The Challenge: The primary concern in any HRC application is ensuring the safety of your employees. Without proper management, you risk injuries and failure to comply with safety standards.

The JHFOSTER Solution: We help you build a safe system from the ground up and understand the difference between collaborative robots with built-in safety features like power and force limiting and industrial robots that require external safety equipment like fencing and sensors. As your partner, we ensure your application is designed to meet all necessary safety standards because safety depends on the entire process, not just the robot.

Fostering Worker Acceptance and Trust

The Challenge: Employees may be hesitant or fearful of working with robots, worrying about their safety and job security. This can lead to low morale and slow adoption.

The JHFOSTER Solution: We help you frame automation as a tool that empowers your workforce. HRC applications are designed to take over dull, dirty and dangerous tasks, freeing skilled workers for more valuable and engaging roles. We provide the training and support needed to ensure that your team feels confident and safe working alongside their new robotic counterparts.

Optimizing Workplace Ergonomics and Safety

The Challenge: Simply placing a robot next to a human isn’t enough. A poorly designed workspace can create bottlenecks, force awkward movements and reduce the efficiency you are trying to gain.

The JHFOSTER Solution: Our automation experts evaluate your entire workflow. We help you design a dedicated collaboration space that optimizes the flow of work for both your employees and the robot. By engineering the layout for seamless interaction, we ensure your HRC system enhances productivity and creates a more ergonomic environment for your team.

Successful Integration and Production Monitoring

The Challenge: Integrating a robot into an existing production line can be complex. Ensuring it communicates correctly with other machinery and effectively performs its task requires specialized expertise.

The JHFOSTER Solution: We are your partner through the entire lifecycle: Evaluate. Design. Integrate. Support. Our engineers have decades of experience integrating customized automation solutions. We handle the entire installation process, ensure all components work together seamlessly and provide the support you need to keep your system running at peak performance.

Industries and Applications Benefiting from HRC

Adoption of HRC is widespread across many industries and in many applications because human-robot collaboration boosts productivity, safety and product quality.

Industries that benefit from HRC include:

- General manufacturing

- Medical device manufacturing

- Food and beverage manufacturing

- Warehousing

- Automotive manufacturing

- Agriculture

Applications that gain efficiency with HRC include:

- Pick and place: Bin picking, sorting and kitting.

- Material handling: Placing objects on or removing objects from conveyors.

- Machine tending: Loading raw materials and unloading finished parts.

- Assembly: Assembling components as they move along the production line.

- Packaging and palletizing: Placing finished goods into packages. Stacking items onto pallets.

- Quality inspection: Holding items in front of a camera for inspection. If equipped with machine vision and machine learning, recognizing patterns for quality control.

- Dispensing: Applying adhesives, sealants and paints.

- Welding: Providing high-quality welds.

Your Partner for a Safer, More Productive Workforce

JHFOSTER is more than a distributor. We are your robotic and automation partner, supporting businesses with cobot integration. We provide the expertise and end-to-end support to ensure your investment in human-robot collaboration is safe, productive and profitable. Ready to make your workplace safer and more efficient? Connect with a JHFOSTER robotics specialist to learn more about how HRC can increase your profits. Get a quote today.