Can Robots Lower Labor Costs and Solve Labor Shortage For Your Company?

Over the last 50 years the cost of labor in manufacturing has risen steadily. The willingness of many people to perform highly repetitive tasks on assembly lines has decreased. As a result, labor shortages have increased. Can robots lower labor costs and solve labor shortages?

Where Can I Save Costs?

With robotic automation products, you benefit from these key cost saving features;

- Top Quality – High quality products provide consistency and precision allowing significant savings.

- Avoid Waste – Robots perform with exact accuracy, saving valuable materials.

- Space Efficiency – Industrial robots compact bases fit in confined spaces saving valuable floor space.

- Production – Reducing production time increases profits.

- Labor-Cost – Repetitive tasks can be given to robots making manufacturing more efficient and cost-effective. This lowers chance of strain injuries caused by repeaintg motions.

- Safe – Robots provide safe work environments along with fewer mistakes. They can perform dangerous and dirty jobs that humans aren’t safe performing.

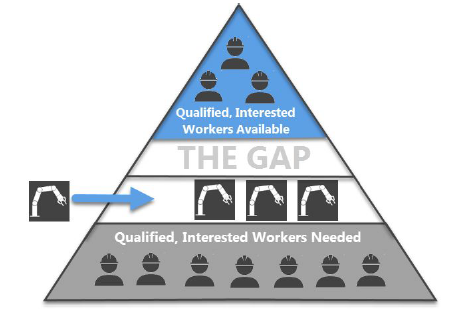

How Robots Solve Labor Shortages

You can’t stop people from retiring, of course, but that

doesn’t mean there’s nothing to be done. In fact, old manual assembly lines have already been largely replaced by automation. However, many places still exist to automate the tasks people don’t want to do or aren’t well suited for. That’s where robots come in.

Collaborative robots solve labor shortages. Furthermore, they are a great example of new automation options that can help solve some labor shortage problems. By automating those tasks, you’ll free up those workers to take on other jobs that are harder to fill.

Robotic ROI

The equivalent hourly cost of robot labor has steadily declined. One thing that’s not often discussed with collaborative robots is their ability to provide quicker return on investment (ROI) than their heavier, more dangerous industrial counterparts. Furthermore, collaborative robots are traditionally cheaper than industrial robots, and still provide a much faster ROI when accounting for this fact.

Our selection of collaborative robots gives you all the advantages of advanced robotic automation. Further, our robots don’t have any of the traditional added costs associated with robot programming, set-up, and dedicated, shielded work cells. Finally, robotic automation is affordable for small and medium sized enterprises.

The main challenge for manufacturing plants and industries is the desire to increase production output while lowering costs. As a manufacturing manager or engineer, this concept is probably part of every work conversation you have. However, incorporating robotic systems can help you solve these problems, and in addition, robots can lower your labor costs.

Be Prepared for a “New Problem”

Old problem: Dull, dirty jobs no one wants to do.

New problem: Working with robots might require more technical skills. Fortunately, many cobots are easy for people to use, even if they don’t have experience with robots. Cobots with touch-pads can be programmed simply and intuitively—no coding knowledge needed. As a result, now an unpleasant job can become “cool,” thanks to a robotic helper!

How You Can Fill the Gap: Problems and the Cobot Solution

Problem: Dull, repeating movements.

Example solution: To save the human from movements that cause repetitive strain injuries, use a cobot to place several screws on a line, and then have a human worker do the final screwing task or verification.

Problem: Dirty jobs.

Example solution: A cobot could get rid of a toxic product such as glue or other chemicals.

Problem: Dangerous tasks.

Example solution: A cobot could tend a machine that needs extra care, such as unloading a brake press.

Calculate Your Savings Now

JHFOSTER distributes robotic lines and robotic accessories to help you leverage your production costs and streamline your automation applications. Our ROI Calculator shows the potential savings of incorporating a robot verses manual labor for production. Calculate your savings now or learn more on ways to increase production output while maintaining costs as low as possible. Also, our team of experts are positioned to support your productivity and efficiency needs with this versatile product. Please contact us today at 651.452.8452 or email us to learn more about this or any of our product offerings.

Robotic Systems & Labor Shortage FAQ’s

1. Pick and Place

2. Injection Molding

3. CNC

4. Packaging and Palletizing

5. Quality Inspection

6. Assembly

7. Polishing

8. Machine Tending

9. Screw Driving

10. Lab Analysis and Testing

11. Gluing, Dispensing and Welding

12. Your Industrial Robot Application

Robots are easily programmable without the necessity for pricey programmers. Your first robot could be up-and-running in only half day because no customer coding is needed. In addition, JHFOSTER offers onsite training so you can get to know your robot quickly and affordably.

Collaborative robots are safe to work with because of their many safety features. In fact, safety zones allow for robots to work at a slower speed while humans and other objects are in the area, and work faster when no human life or objects are in its vicinity. The patented safety system also monitors for eight safety factors: joint position and speed, TCP position, orientation, speed and force, momentum and force of the robot.

[printfriendly]