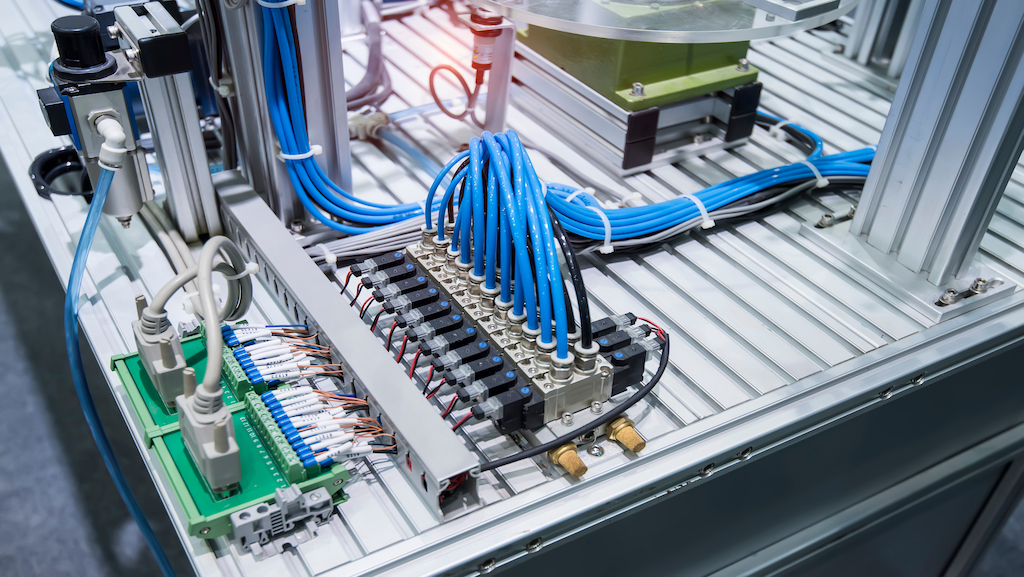

Pneumatic Control Valves

A lot of things can go wrong in pneumatic systems. Potential causes could be incorrect components, poor air quality, or lack of maintenance. These issues can be time-consuming and costly. Choosing the most effective parts is more than just considering their applications.

One integral component that should not be overlooked are pneumatic valves. Not only do they control the direction of airflow in critical operations in the system, but they are also a possible source of issues, especially if they are not of good quality.

Issues with pneumatic control valves can lead to more costly problems all over the system. By reading this, you are already taking the first step in avoiding this problem — because choosing the right air valve starts with choosing the right valve manufacturer.

At JHFOSTER, we provide a wide range of reliable pneumatic valves for an array of applications.

What Is a Pneumatic Valve?

Electric pneumatic air control valves are the components responsible for regulating the rate, pressure, and amount of compressed air that passes through a pneumatic system.

Pneumatic air valves perform a guiding and dosing function via regulating and locking elements. They’re controlled by special mechanical, pneumatic, or electromagnetic signals.

Pneumatic control valves can perform all kinds of tasks in varied complexities. They can be customized according to the specific application. Each type of valve is characterized by the possible mechanism positions and the number of ports or flow lines.

Which industries use pneumatic valves?

Air control valves are typically constructed from high-quality materials such as aluminum, stainless steel, and carbon steel. They are widely used in all types of manufacturing as well as packaging, automotive assembly, food and beverage processes and more.

A variety of industrial and manufacturing processes involve the precise movement and flow direction of hazardous fluids and chemicals. Strong, powerful systems that can operate under heavy payloads are required to achieve this and pneumatic valves help these systems maintain precise movements even in intricate pipe networks.

What Are the Types of Pneumatic Valves?

There are several types of pneumatic control valves, and deciding which one to use depends on the application. They may be categorized according to the number of exit or entry points or according to the number of airflow paths. There are also mechanical, electric, or air-operated valves. Here are a few examples of the possible classifications:

• Two-, three-, or four-way directional valves – These pneumatic valves are usually classified based on the number of ports they have. Each port serves a unique purpose – whether it be inlet, exhaust, or outlet.

• Open or closed resting state valves – Valves with normally open or normally closed functions can serve to regulate airflow when in their resting(unactuated) state. Normally closed will not allow any airflow through whereas normally open will allow airflow through.

• Valves that use spring offset mechanism – Some pneumatic control valves have a spring mechanism that is used to close or open ports when the valve is in its unactuated state. These springs often work to return the valve to its prior position.

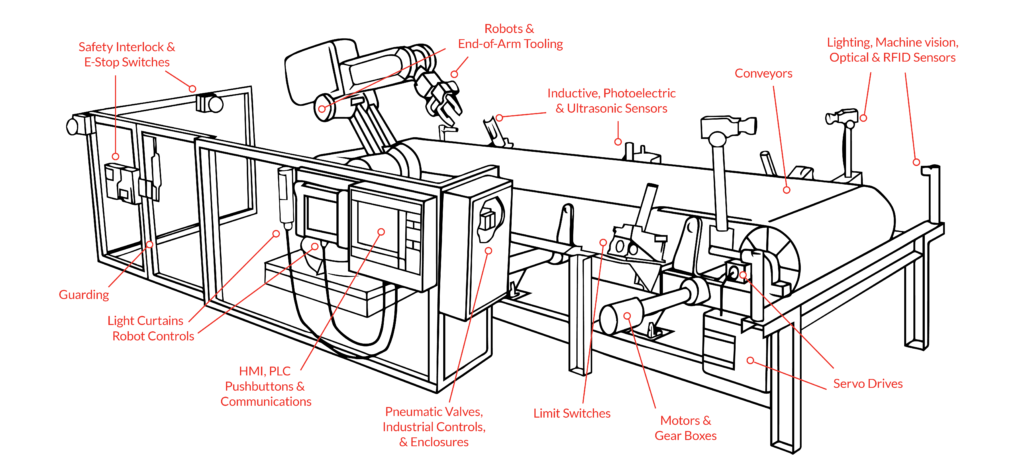

Other Recommended Solutions

Pneumatic and other systems in your manufacturing operations can be complex and overwhelming. The JHFOSTER team can be your partner in choosing the right components, in the right systems, for the right applications every time.

Expect us to invest in understanding your business to better recommend solutions that are in line with your needs and objectives.

JHFOSTER: Your Partner in Pneumatic Control Valves

If you want an effective, fully customizable industrial system, our team at JHFOSTER is here to be your partner in pneumatic valves. Over the years, we have worked with clients across industries and have provided everything from air control valves and other integral components to entire systems. This experience has given us insights into the inner workings of most systems, insights that will serve you during our time working together.

Our strength as an air control valve distributor comes from our willingness to help you overcome inefficiencies and unnecessary costs using systems that are designed for your unique use case. We value relationships with our clients since your success is also ours.Whether you need a specific air operated valve or are looking around for the best one for your system, you can click here to get a quote.

Automation Library

Maximize the benefits of automation for your manufacturing operation by getting to know the systems, applications, and components that make up your processes. The more in-depth understanding you have of automation can lead to more efficient, productive, and even durable systems

Visit our automation library for more resources and to learn more.

TECHNOLOGY

Motion & Mechatronics

- Rotary/Linear Motion

- Sizing/Consultation

- Motors/Drives/Control

- Robots

- Conveyors

Sensors & ID

- Presence

- Inductive/Capacitive

- RFID/Bar Code

- Safety

Data

- Networks (LAN/WAN)

- HMI/Web Panel

- Remote Access/Monitor

PRECISION MACHINING

- Horizontal Millin – 5 axis

- Vertical Milling = 5 axis

- Turning (up to 14″)

- Swiss Turning (approximately 3 – 20 mm)

- CAD Solidworks

- Gibbs & Surfcam

ELECTRO-MECHANICAL ASSEMBLY

- UL508A Certified Panel Shop

- Control Panel Build

- Enclosures

- Value Added Sub Assemblies: Pneumatic, Mechanical, Electrical, Build to Print

- Horizontal Millin – 5 axis

- Vertical Milling = 5 axis

- Turning (up to 14″)

- Swiss Turning (approvximately 3 – 20 mm)

- CAD Solidworks

- Gibbs & Surfcam

Frequently Asked Questions

First, make sure the valve is compatible with the media and pressure passing through it. Other things to consider include the method of valve actuation, the return method that will take the valve back to its original state, flow capacity, and valve configuration.

Pneumatic control valves come in different sizes and specific functions. JHFOSTER can help you select the type best suited for your requirements.

Automated systems boost efficiency and productivity while helping to lower overall operational costs. Automated technologies also help eliminate bottlenecks that result in lost time and revenue, giving you back vital resources to grow your business and improve market performance.

Request More Information