Use Demand (Dry) Storage for an Efficient Compressed Air System

This post will focus on a type of supply-side storage: demand (dry) storage. Before diving in, remember that you should consider control and demand storage as separate storage solutions based on their purpose.

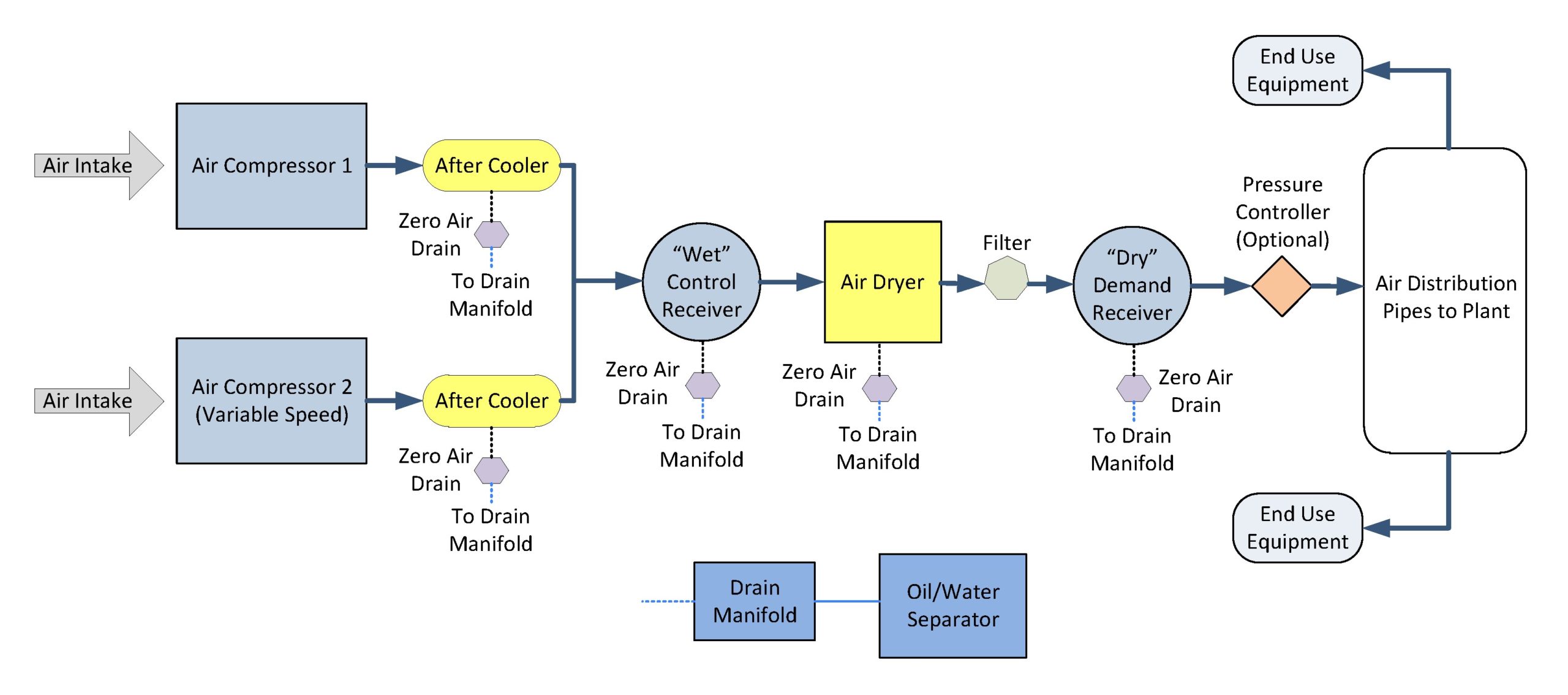

When using control (wet) storage in your system, the main goal should be improving the efficiency of the compressor controls. Other issues such as moisture removal or supplementing demand storage should be considered after efficiency. Engineered separation and condensate drain systems better achieve moisture removal than demand storage.

Using control storage instead of demand storage may seem logical, however, control storage remains unfiltered and wet. This increases intermittent flow levels and could exceed the capacity of air preparation equipment. As a result, the distribution system receives unfiltered and wet air.

Is Demand Storage Right for You?

Definition of Demand Storage

The easy definition of demand storage is a pre-conditioned volume of compressed air located on the supply side of the system. Generally, the intentional creation of a pressure differential at a level above system pressure creates usable air storage.

Should You Consider Demand Storage?

It is not a question of will a compressed air system function without demand storage, it is a question of how well. If reliability, productivity, and efficiency are not your focus, then a compressed air system can operate without demand storage. Many industrial plants operate without demand storage today. As a result, these plants usually show one or more of the following signs:

- Operating at a higher system pressure than necessary

- Increased system air demand

- More on-line compressor horsepower than needed

- Excessive fluctuation in system pressure levels

- High maintenance costs

Compressor manufacturers design compressor controls to first and foremost protect the compressor. Only then do they attempt to satisfy the discharge pressure setting. In some cases, they design for limited part-load efficiency and networking capability.

Without demand storage, the controls of an air compressor are required to react to support all demand events in the time frame which they occur within the compressed air system. This was not the original intent of compressor controls.

It does not matter what type of compressor or compressor control is used, the expectation of reacting effectively and efficiently to the changes that may occur in a compressed air system is impractical. With the proper amount of demand storage applied to the air system, the benefits should include:

- Lower and consistent system pressure

- Reduction in system air demand levels

- Reduction in on-line horsepower

- Improvement in overall system efficiency

- Consistent quality of compressed air

- Reduction in maintenance costs

The Role Demand Regulation (Flow Controller) Plays in the Creation of Demand Storage

One of the most important factors of demand storage creation is the intentional production of a significant pressure differential. If we rely only on naturally occurring pressure drop, very little if any, demand storage will be generated. For example, a 1000-gallon receiver with a 2 psid will produce only 18 cf of demand storage. Point of use regulation could be used as an alternative to demand regulation in the creation of demand storage if each point of use was properly regulated at its lowest effective pressure level.

Statistics and experience have shown, however, that less than 50% of point of use applications have regulators installed and many of those are adjusted incorrectly. Installation of demand regulation (flow controller) along with a storage receiver ensures an effective generation of demand storage.

The application of a flow controller allows the system designer to not only create a pressure differential but also a separation between the supply and demand sides of the compressed air system. No longer is it the responsibility of the compressor controls to react to each demand event in the system. The concern is only to maintain demand storage. Supporting demand events now becomes the responsibility of the flow controller along with demand storage.

This allows the system designer to more effectively control the rate of change and reaction time within the compressed air system by controlling the expansion of air across the flow controller. More importantly, the individual can achieve this at a greater speed and capacity level than on-line horsepower alone.

Determining the Amount of Demand Storage Required

Determining the amount of demand storage needed varies due to system dynamics and constraints, as well as, additional requirements of the system. System considerations might also dictate the need for other storage concepts.

You must use engineering principles to design the application of demand storage. Without a thorough audit of the system, the results might not meet expectations. After all, you would not want to over or under create demand storage. Correctly performed audits should identify the optimum amount of demand storage needed to produce the results you expect.

How Much Demand Storage Do I Need?

The information needed to determine the amount of demand storage required would include:

Minimum System Pressure Required

A properly performed audit should include the demand side as well as the supply side of the compressed air system. Each compressed air user should be individually evaluated for the minimum required system pressure. It is common that the perceived pressure need is higher than necessary due to conductance issues that occur most often within 10 ft. of the compressed air user. You must address these issues to find the true minimum pressure requirement.

Pressure limitations of the air compressors

Confirm the design pressure range of each compressor in the system. If it is a load/no load control, what are the cut in and cut out pressures? If you are using a type of compressor network control system, identify the lowest pressure level expected within the parameters of the control system. *

Size and duration of demand side events

What is the magnitude, cycle time, and duration of the demand event? The longer the event duration, the shorter the recovery time, and the greater the magnitude of the event, the more problematic it becomes to utilize only demand storage.

Time required for trim machines to start and load

If there is a multi-compressor installation where one or more compressors will be considered for trim, it is critical to know how long it will take a compressor to reload or come online. This is especially critical for larger horsepower compressors such as centrifugal, where the time needed to go from an off position to a loaded position could be more than one minute. Other considerations would be a control permissive that would delay start-up or reloading sequences.

Supply side pressure drop

The available useful differential between the storage vessel, flow controller, and the volume of the storage receiver itself determines the capacity to create demand storage. Once the pressure capability at the discharge of the compressor is identified, two factors must be considered:

- Virtually all compressed air systems have purification equipment (i.e. filters, valves, and air dryers) installed between the compressor discharge and the storage vessel. Purification equipment is a source of pressure drop that could range from 5 to 15 psi. It is critical to minimize this pressure drop as much as possible as it will reduce the differential that is possible in the creation of demand storage.

- A 3-5 psig differential should be maintained between supply pressure and the system pressure setting on the demand regulator. If the upstream pressure and the system pressure at the demand regulator equalize, the compressed air system goes dynamic with the supply side tracking the demand side and system pressure control is lost.

Summary

The goal of this article is to provide basic information on the definition, purpose and advantages of demand storage. However, we encourage you to reach out to specialists when attempting to increase efficiency in your compressed air system. If you would like additional information, please call or email us.

Footnotes: *VSD compressors have the advantage of being able to increase the system pressure. However, be aware that raising this pressure level above the design point will reduce the capacity of the compressor.

Adapted From 2011 Satellite Newsletter Written By Ron Nordby