Linear Guideways Enhance Modern Medical Equipment

In the healthcare industry, precise and reliable equipment is essential for...April 18, 2024

Read More

Creating Smart Factories with Automation and Integration

As more manufacturers take steps toward Industry 4.0 and the smart...April 16, 2024

Read More

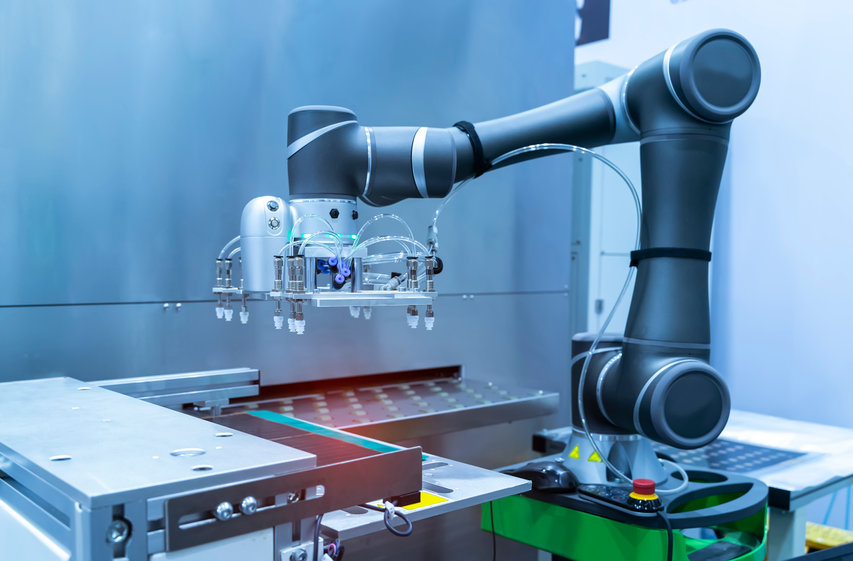

Getting the Most from a Collaborative Robot Project

Although many experts state that collaborative robots are user friendly, it...April 11, 2024

Read More

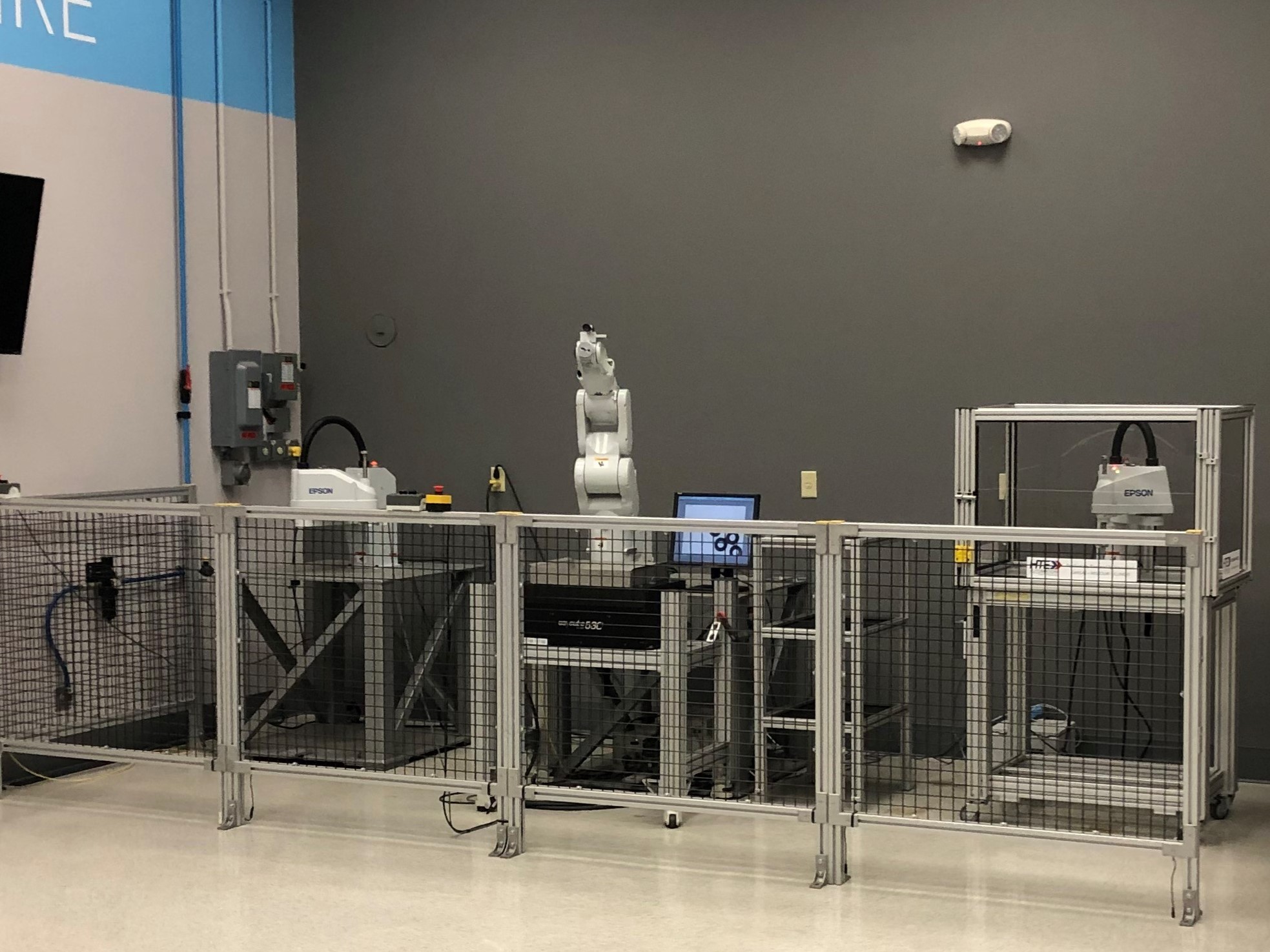

T-Slot Aluminum Framing Delivers Form and Function

Traditionally the factory floor was designed as a functional space built...April 9, 2024

Read More

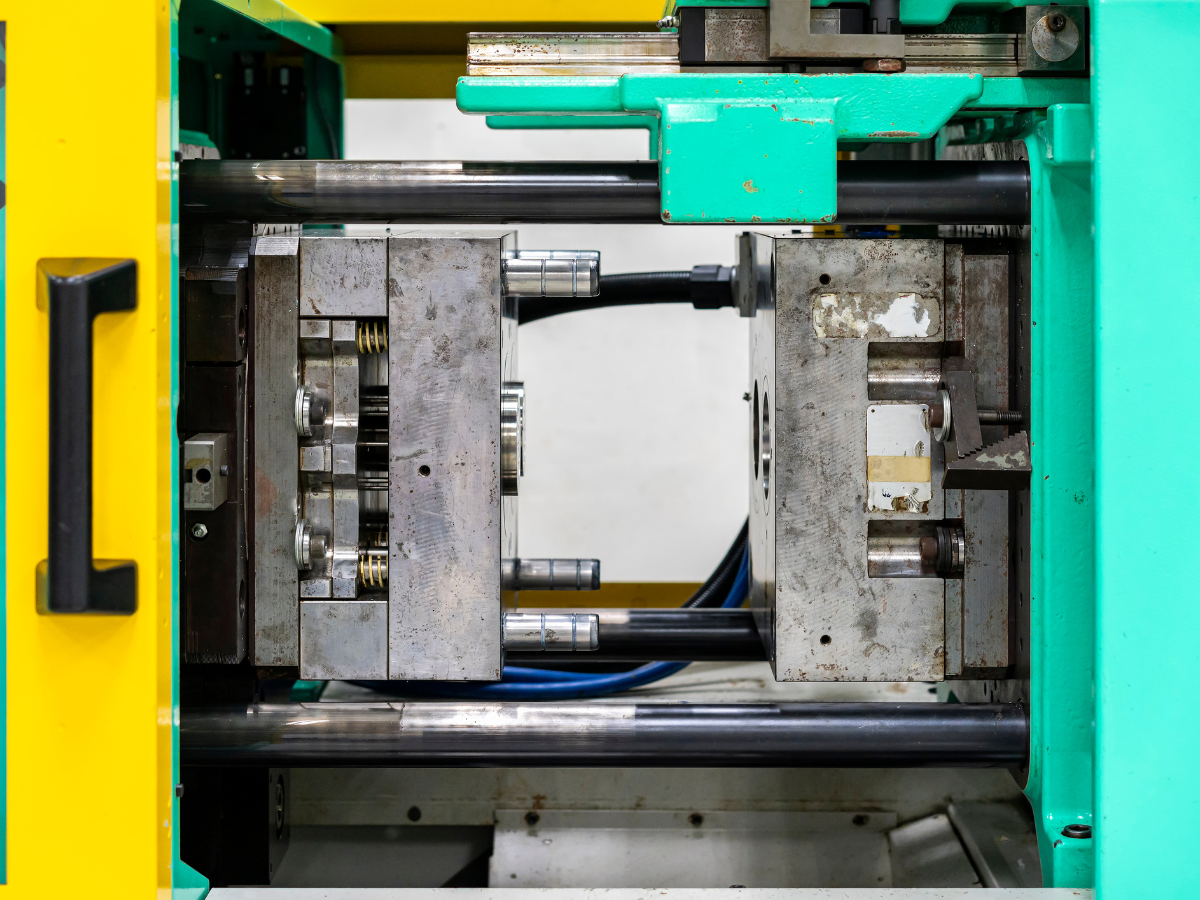

Injection Molding Techniques Call for Flexible Parts Feeding Systems

Traditional injection molding typically involves the use of volumetric and gravimetric...April 4, 2024

Read More

Automated Inspections Maximize Food and Beverage Quality Assurance

Food safety and customer satisfaction both play a vital role in...April 2, 2024

Read More

6 Benefits of Pick and Place Robots in Medical Manufacturing

Due to increasing market demand and strict governmental regulations, medical device...March 28, 2024

Read More

Oil-Free and Oil-Less Air Compressors Support Sustainability

While oil-free and oil-less air compressors were traditionally adopted by industries...March 26, 2024

Read More

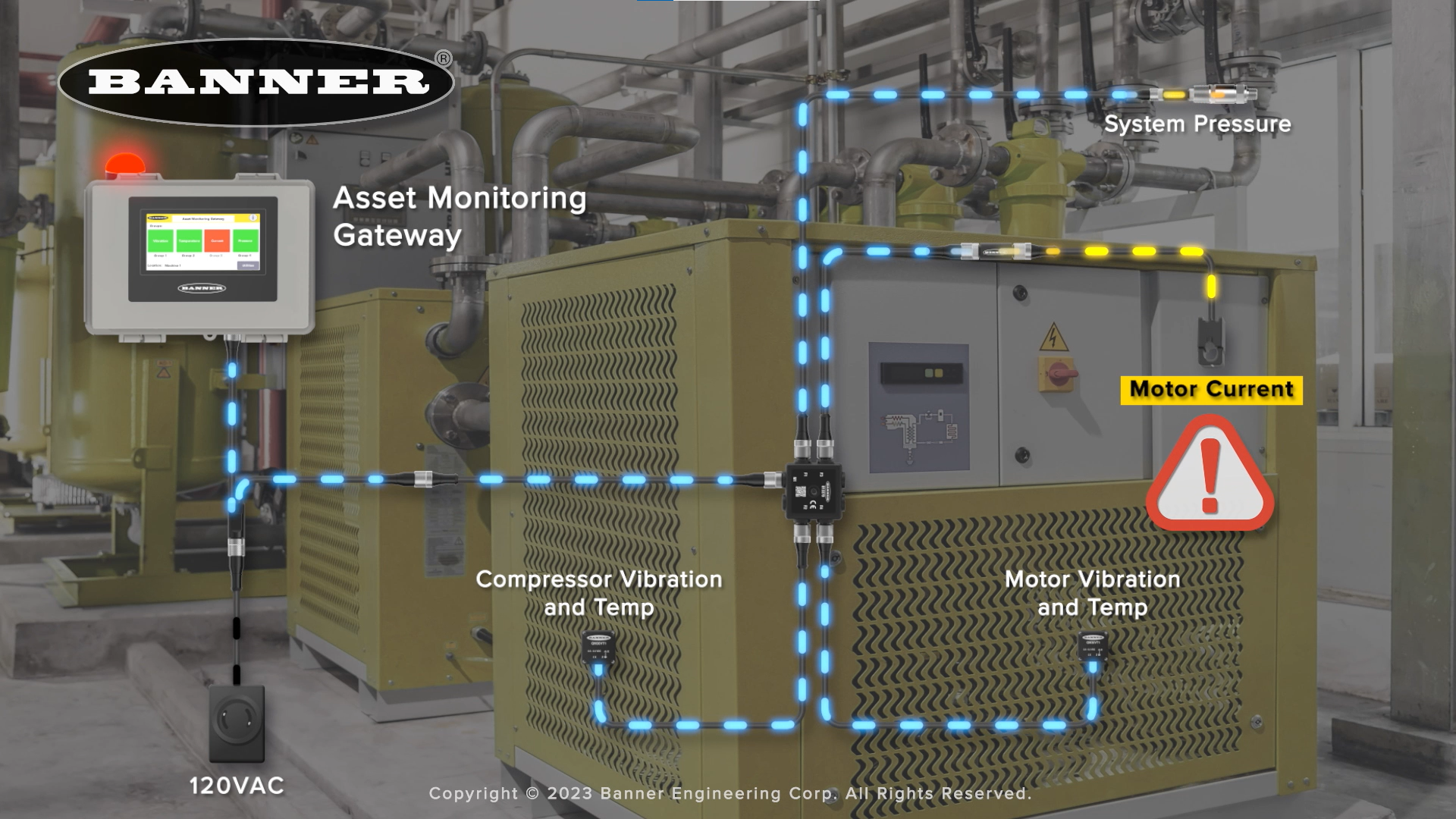

Asset Monitoring with a Simplified Solution

Traditionally, asset monitoring, the practice of collecting and analyzing data about...March 21, 2024

Read More

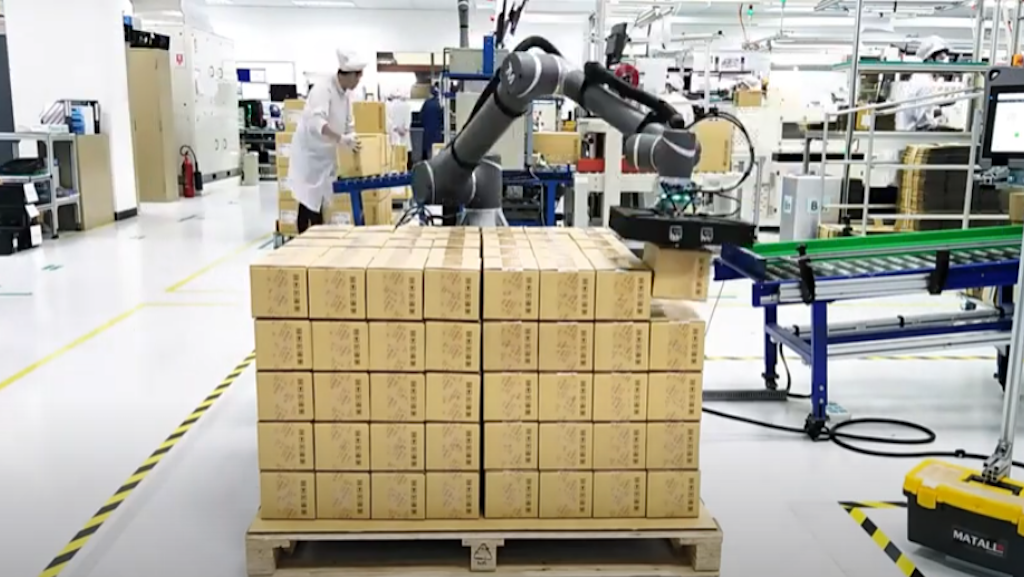

6 Benefits of Automated Palletizers in the Pharmaceutical Industry

Like most manufacturers, producers of pharmaceuticals are currently experiencing a growing...March 19, 2024

Read More