Industrial Electric Actuators

The ability to automate processes in the manufacturing industry has been a huge step taken by many companies. Although automation streamlines operations and enables them to be more time-efficient overall, parts of the automation process need to be seamless to achieve best results.

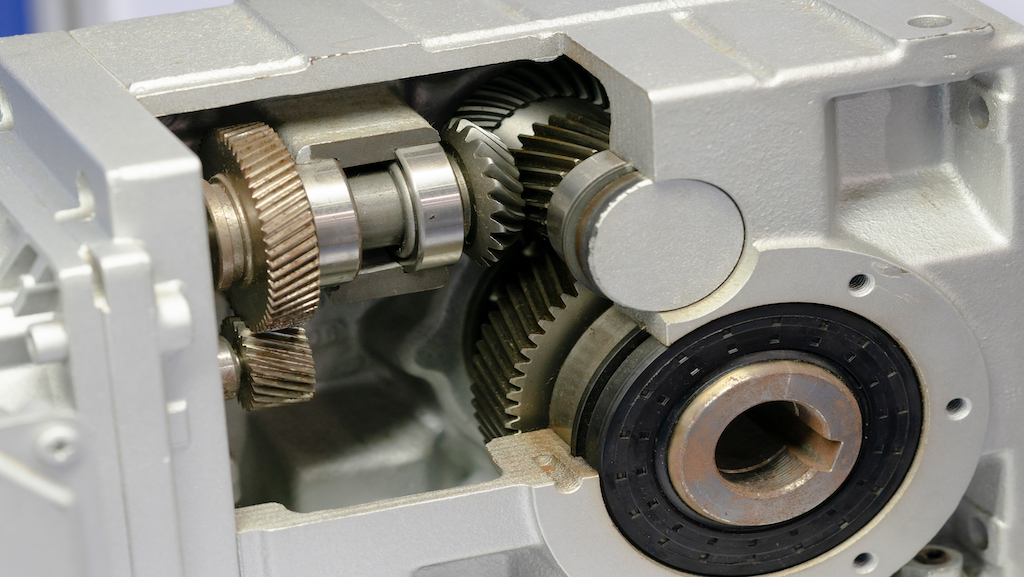

One component necessary to making this happen is electric actuators. These are actuators that convert electrical energy into mechanical torque, force, and linear motion. They are essential to the automation of certain processes of manufacturing. Industrial electric actuators are commonly used for creating the movement of a load using an electric motor to generate the needed force for the actuator and load to move. They can be powered by either direct current from a DC power supply or batteries, or alternating AC current. Electric actuators have far-reaching applications across several industries including manufacturing, agriculture, energy, food production, consumer electronics, and automotive.

The smallest electric actuators can be used in the medical device manufacturing process. Midsized actuators are often customized for different industrial uses with the largest electric actuators are used in pressing, parts clamping, punching, and many more applications. Electric cylinder actuators, or simply electric cylinders, are increasingly becoming a favorite for many industrial applications, overshadowing pneumatic actuators, for their versatility, low maintenance costs, and improved motion control.

Pneumatic vs Electric Cylinder Actuators

Electric actuators are the default choice when an application requires more precision. They have different power and temperature requirements to operate at optimal conditions. Unlike pneumatic actuators, when it comes to lower temperatures, electric actuators can thrive without the risk of condensation freezing and blocking the air supply lines.

An electric actuator is the only viable option when compressed air is not available. Most of these actuators have enclosure options that adhere to the standards set by NEMA VII. Another advantage of electric actuators is their low torque to weight ratio, which is required in some applications. At the end of the day, the needs of the application and the industry dictate which actuator is more suitable.

Recommended Products and Solutions

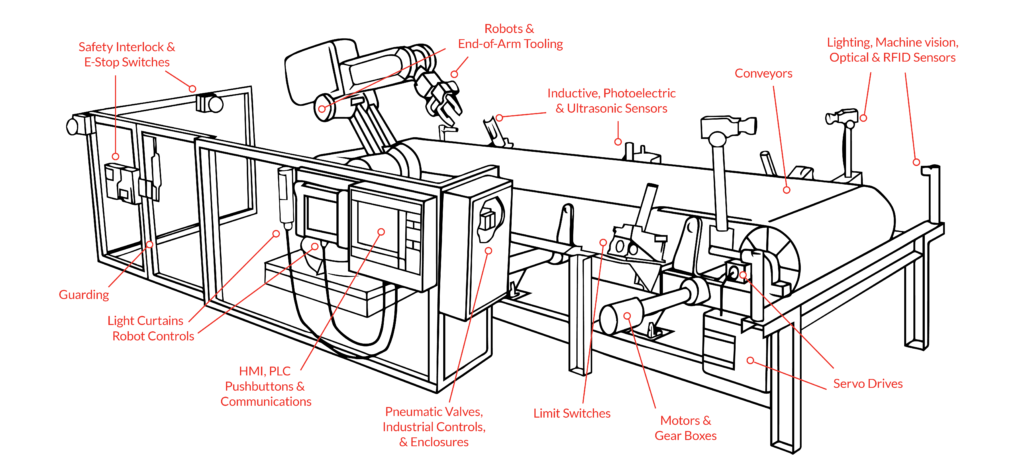

JHFOSTER distributes a wide range of control panels, speed reducers, and safety solutions, including sensors and signaling products for detection and protection.

Electric Actuators for Diverse Industries

JHFOSTER equips industrial facilities of all kinds with electric actuators to improve and streamline a variety of industrial and manufacturing applications.

- Manufacturing and Electronics – electric actuators power precise movements to improve production quality and speed. They may also be used for cutting equipment and valve operation.

- Automotive – our actuators provide the high and precise positional accuracy necessary in automotive production.

- Food and Beverage – in facilities that require higher levels of sanitation, electric cylinders are an ideal choice because they don’t contain any air or fluids that can leak, are easy to clean, and are corrosion-resistant.

- Agriculture – agricultural equipment that requires intelligent movements uses electric actuators, instead of bulkier hydraulics that can be an environmental hazard.

- Energy – electric cylinder actuators are essential to energy and cost efficiency in modern power generation, including solar energy farms.

Contact us today for inquiries.

Choose JHFOSTER Equipment

For more information about industrial electric actuators and the variety of their applications, check out our FAQ sheet.

Literature Library

Looking for additional information? Check out JHFOSTER’s Automation Library.

TECHNOLOGY

Motion & Mechatronics

- Rotary/Linear Motion

- Sizing/Consultation

- Motors/Drives/Control

- Robots

- Conveyors

Sensors & ID

- Presence

- Inductive/Capacitive

- RFID/Bar Code

- Safety

Data

- Networks (LAN/WAN)

- HMI/Web Panel

- Remote Access/Monitor

PRECISION MACHINING

- Horizontal Millin – 5 axis

- Vertical Milling = 5 axis

- Turning (up to 14″)

- Swiss Turning (approximately 3 – 20 mm)

- CAD Solidworks

- Gibbs & Surfcam

ELECTRO-MECHANICAL ASSEMBLY

- UL508A Certified Panel Shop

- Control Panel Build

- Enclosures

- Value Added Sub Assemblies: Pneumatic, Mechanical, Electrical, Build to Print

- Horizontal Millin – 5 axis

- Vertical Milling = 5 axis

- Turning (up to 14″)

- Swiss Turning (approvximately 3 – 20 mm)

- CAD Solidworks

- Gibbs & Surfcam

Frequently Asked Questions

No matter what industry you’re in, automation can help enhance your processes and eliminate a variety of common errors that result in wasted time and resources. Automating your operations yields higher productivity, increased performance, and decreased operating costs.

JHFOSTER understands that industrial electric actuator failures can happen at any time. Our technicians respond to repair calls 24 hours a day, seven days a week–including holidays. Call 855.688.0065 for all your repair and maintenance needs.

Request More Information