Category: Electric Actuators

Electric vs. Pneumatic Actuators: Which One is Right for You?

The choice between pneumatic and electric actuators is not always an easy one. However, the two technologies are so different that one can rarely be a replacement for the other. Many variations exist to meet the demands of the compressed air market. There are a few key points that can help you to decide between electric and […]

How to Select a High-Quality Industrial Electric Actuator

With the rise of robotics and automation, electric linear actuators have become an essential component in the processing equipment, assembly machinery, machine tools and robots found in almost every industrial facility. Used to convert the rotary motion of an electric motor into linear motion, electric linear actuators enable industrial equipment to do its job; however, […]

The Truth about Accuracy in Linear Actuators

When specifying a linear actuator, the first question most people ask is: “How accurate is it?” There is no simple answer and it is possible that it’s not even the right question to ask as accuracy may not be the most important parameter for a given application. While accuracy is often viewed as the most […]

Electric Linear Actuators Offer Significant Cost Savings

When selecting a linear actuator, folks often overlook electric actuators because the upfront cost is typically higher than that of fluid actuators; however, due to their precision, flexibility, energy efficiency, environmentally friendliness and low maintenance, the lifecycle cost of electric actuators is often significantly lower than that of the other options. What’s the Difference between […]

A Brief Guide to Electric Actuators

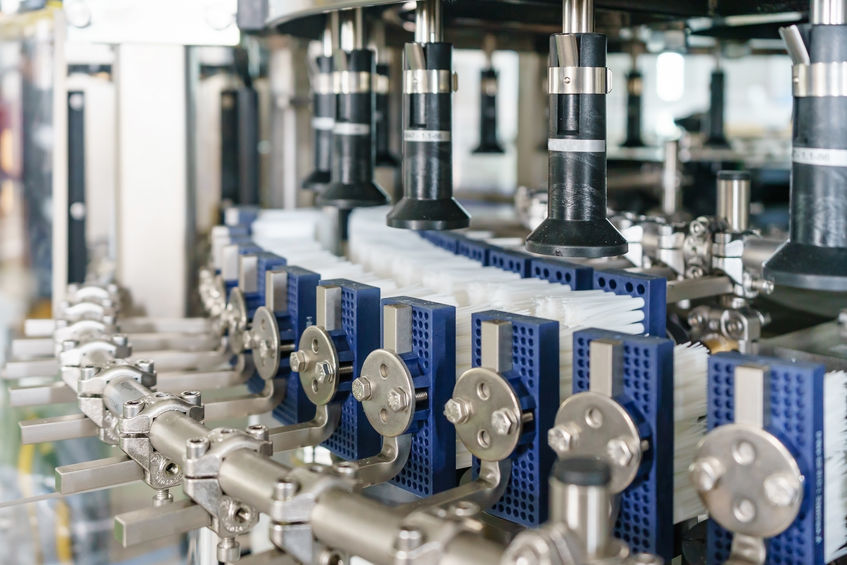

One major component that makes automation possible is electric actuators. These mechanical devices convert electricity into kinetic energy using either rotary or linear motion. Electric actuators work like other types of actuators. The only difference is that it uses electricity as its input. Electricity powers a motor, triggering specific components into motion. The final output […]

IIoT and Smart Manufacturing

Imagine a world where alerts are sent to your phone if a technology within your manufacturing plant malfunctions or requires repair. In this world, systems within your plant could also switch between manufacturing one product to another quickly and seamlessly. Different automation systems talk to each other and coordinate effectively. It sounds almost futuristic, but […]

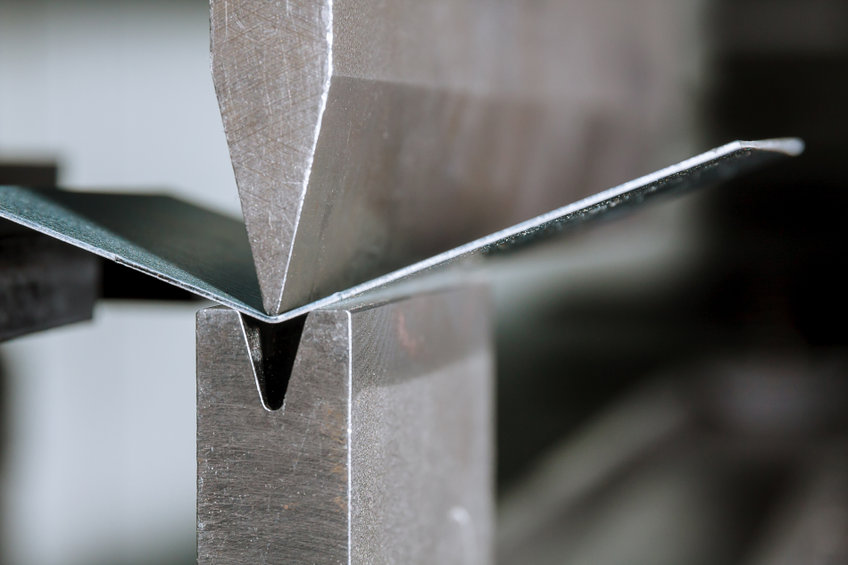

Hydraulic to Electric Actuator: Discussing The Basics

As globalization fosters more competition, manufacturers are finding ways to stay ahead by transforming many of their core processes. This includes converting from hydraulic systems to electrical ones. Both hydraulic cylinders and electric actuators provide many benefits for many linear motion applications. Hydraulics offer high force at affordable costs, while electric actuators boast the same […]

The Usual Suspects in Electric Actuator Failure

From manufacturing machinery and agricultural equipment to electric cars and robots, the electric actuator drives the modern world – literally and figuratively. This reliance is not likely to change any time soon. It means that a deeper understanding of the workings of electric actuators will become increasingly necessary. In developing this deeper understanding, learning about […]

10 Advantages of Electric Actuators

An actuator is a part of a machine or device that enables movement by converting some form of energy into mechanical force with the push of a button. There are various kinds, but the most popular are the hydraulic types which use incompressible liquid as energy. Electric linear actuators have been gaining more traction recently […]

The Dangers of Dysfunctional Actuators

Actuators help streamline manufacturing processes while lowering production costs. However, issues and defects in these components can jeopardize the entire production line and result in severe downtime. In manufacturing, downtime can translate to significant financial losses. It is estimated that downtime causes every factory to lose at least 5% of productivity, with some factories losing […]