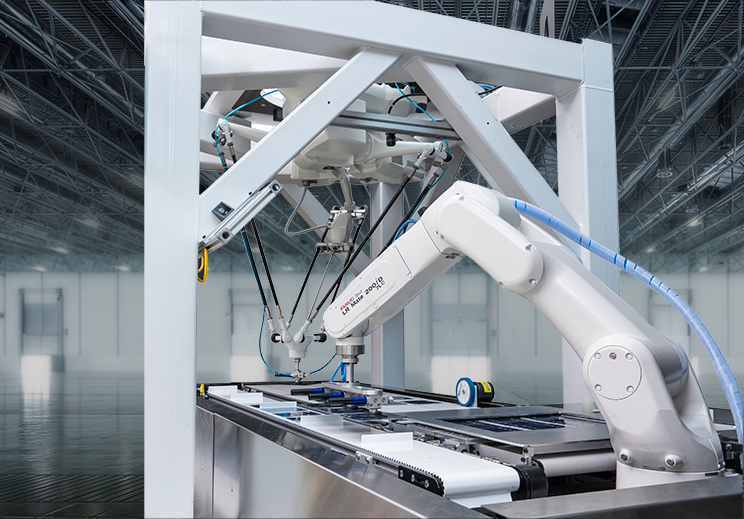

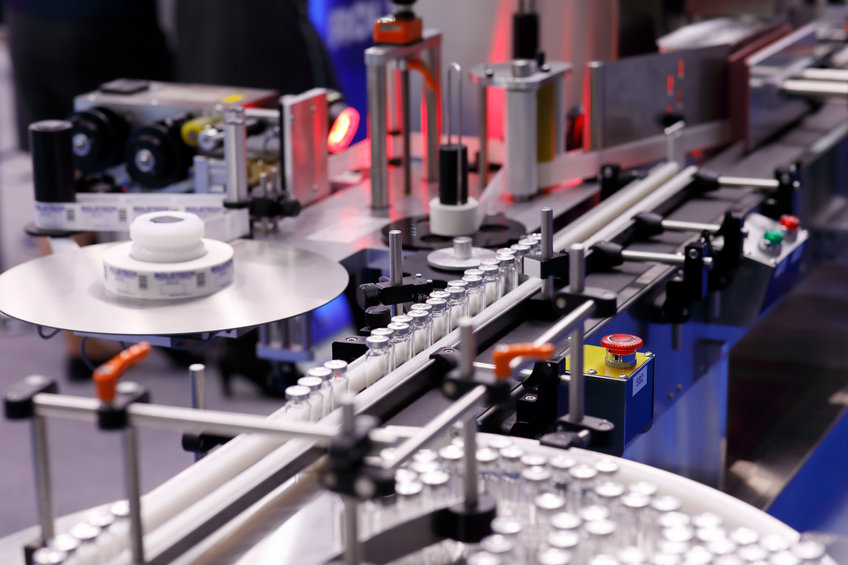

Your Partners for Automation & Robotics Solutions, Machine Components and Comprehensive Systems

JHFOSTER is redefining the possibilities of automation. Building trust, delivering innovative technology and collaborating to provide end-to-end sales, service and support – our driving motivation is to streamline the pathway to automation and deliver lasting value.

Contact us today to find the most effective solution for your needs. We will be there beside you every step of the way.

Our Divisions

Our Capabilities

Contact us today to find the most effective solution for your needs.

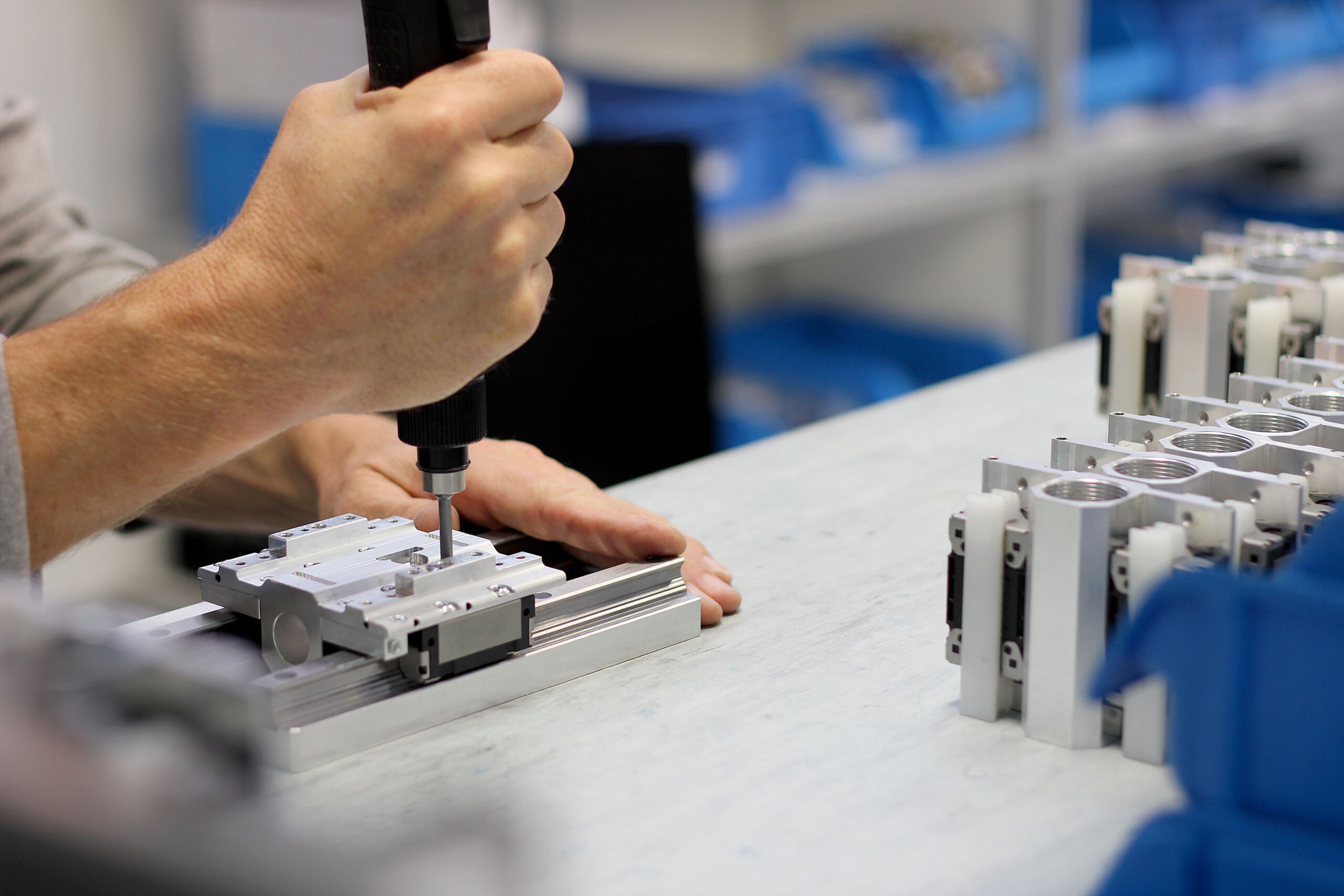

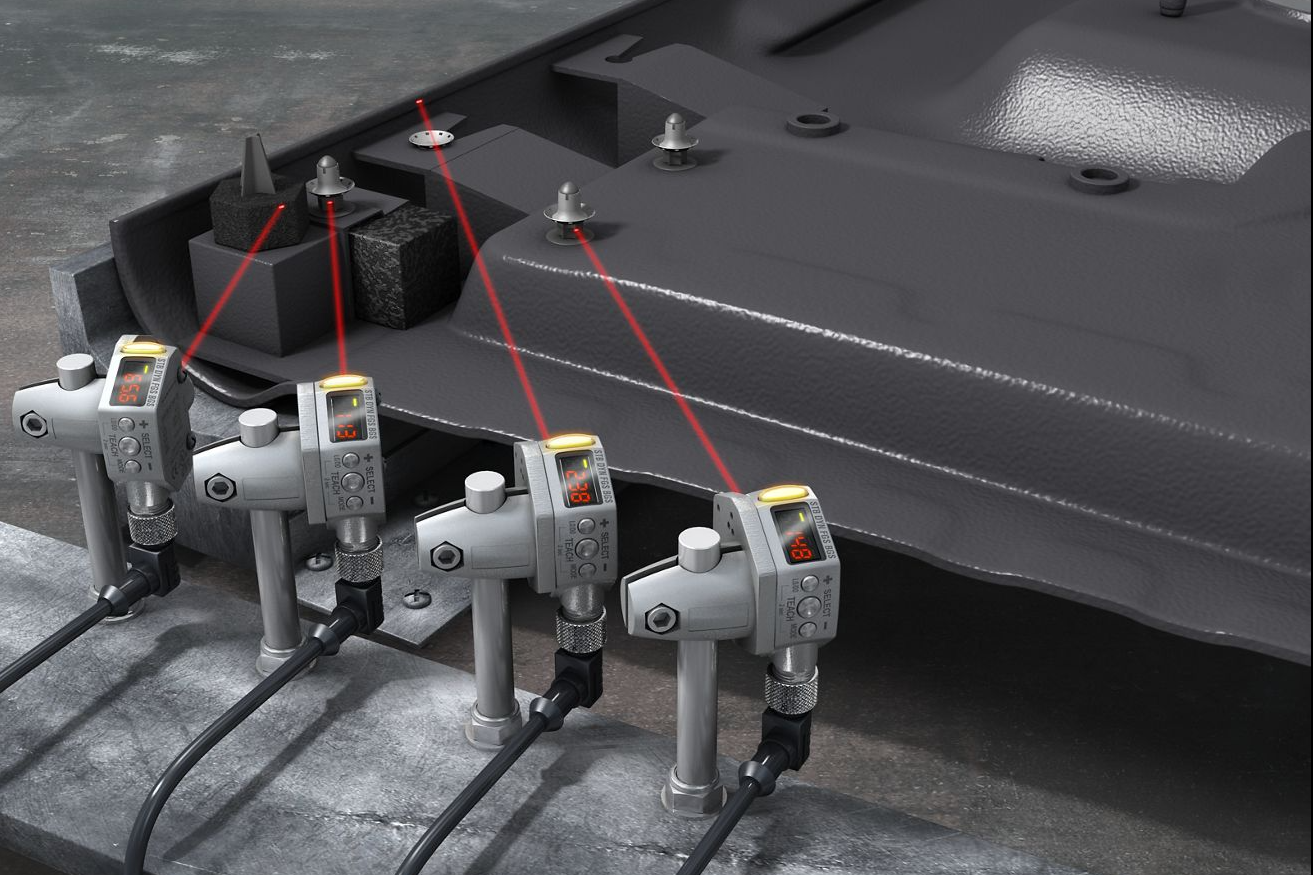

Find The Products That Will Streamline Your Business

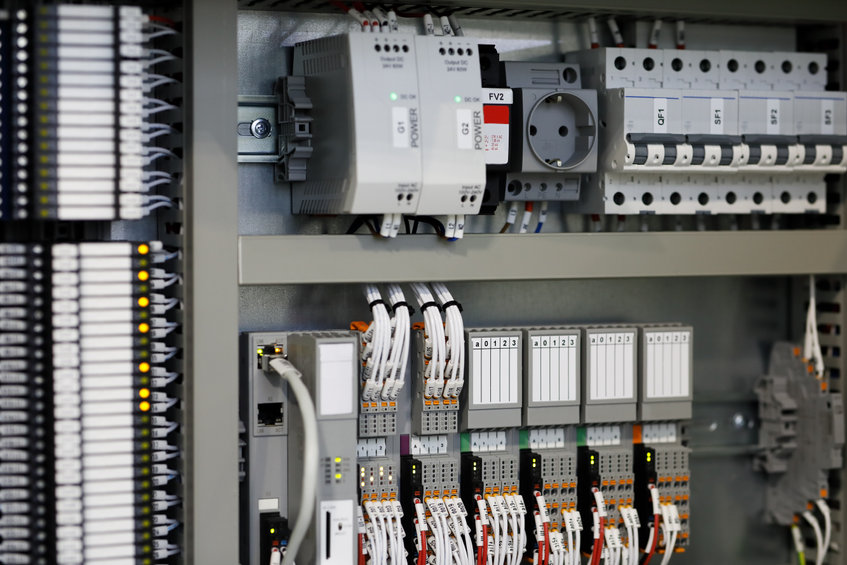

JHFOSTER offers a comprehensive and extensive suite of products from the top manufacturers in the compressed air, automation, and robotics industries, all installed, serviced, and maintained by our experienced team of technicians.

Start working faster, smarter, and more efficiently with our products and services.