Calculate Your Profit

Welcome to the Profit Calculation Library

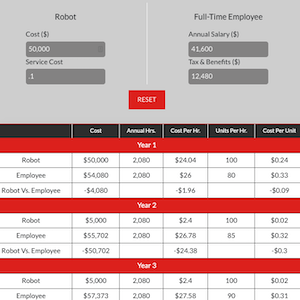

Our Profit Calculation Library is intended to help you gain a realistic estimate of potential savings from purchasing a robot, automated guided vehicle, or compressor package from JHFOSTER. We urge you to explore the possibilities of investing in our equipment through our calculators, and we are eager for you to experience first hand what has made JHFOSTER a respected name in manufacturing. If you have any questions about the projected outcomes from any of our calculators please contact us, or explore our related resources below.

Related Resources – Case Studies, Blog, Resource Library